To successfully bond PTFE to metal, you must use a specialized two-part epoxy adhesive, such as the Araldite AW106 / HV 953U system. However, the choice of adhesive is only one part of the solution. A strong, reliable bond is only possible when the PTFE surface is chemically etched and both the metal and PTFE surfaces are meticulously prepared before application.

The key to bonding PTFE is not found in the adhesive alone, but in a systematic process: chemically altering the non-stick PTFE surface through etching and then using a high-strength epoxy adhesive under controlled conditions.

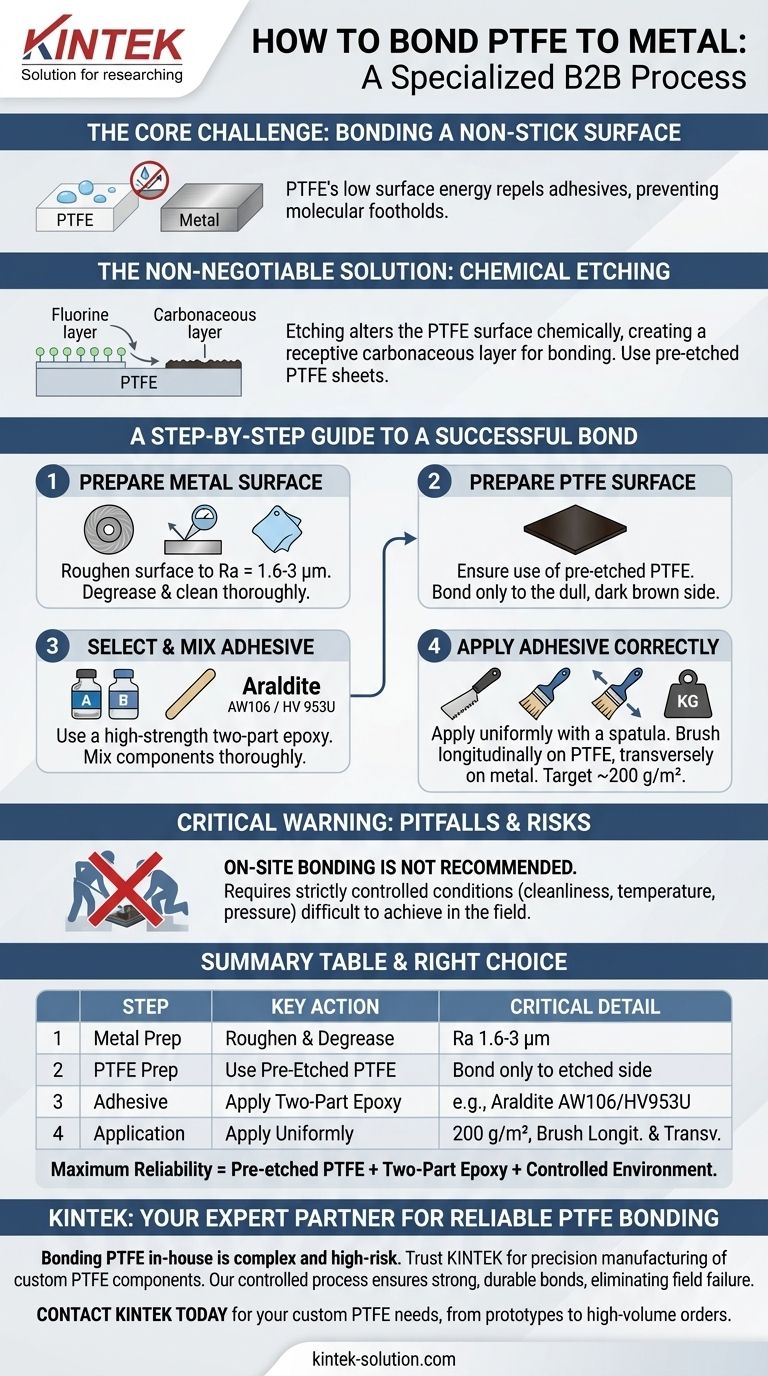

The Core Challenge: Bonding to a Non-Stick Surface

Polytetrafluoroethylene (PTFE) is engineered to have extremely low surface energy, which is what gives it its characteristic non-stick, low-friction properties. This same quality makes it incredibly difficult for adhesives to "wet" the surface and form a strong mechanical or chemical bond.

Why Standard Adhesives Fail

Most adhesives fail on untreated PTFE because they cannot find any molecular footholds to grab onto. The adhesive simply beads up on the surface rather than spreading out and adhering.

The Non-Negotiable Solution: Chemical Etching

To overcome this, the PTFE surface must be chemically modified. This is done through a process called etching.

Etching uses a chemical agent to strip fluorine atoms from the PTFE's molecular backbone, leaving a carbonaceous layer that is receptive to bonding. For reliable results, it is strongly advised to source PTFE sheets that are already pre-etched on one side from the manufacturer.

A Step-by-Step Guide to a Successful Bond

Achieving a durable bond between PTFE and metal is a precise process. Each step is critical to the final outcome.

Step 1: Prepare the Metal Surface

The metal substrate must be prepared to create an ideal surface for the adhesive. First, roughen the surface by grinding, milling, or a similar machining method.

The target surface roughness should be between Ra = 1.6 µm and Ra = 3 µm, and should not exceed Ra = 6 µm.

After machining, the surface must be thoroughly degreased and cleaned with a solvent like acetone, trichloroethylene, or perchloroethylene to remove all grit, oil, and debris.

Step 2: Prepare the PTFE Surface

Ensure you are using a PTFE sheet that has been properly etched on the bonding side. This surface will typically appear as a dull, dark brown or black layer. This is the only side that can be bonded.

Step 3: Select and Mix the Adhesive

A two-part epoxy adhesive system is recommended for its high shear strength. The combination of Araldite AW106 resin and Araldite HV 953U hardener is a proven choice for this application.

Prepare the adhesive according to the manufacturer's instructions, ensuring the components are thoroughly mixed.

Step 4: Apply the Adhesive Correctly

Using a serrated spatula, apply the mixed epoxy uniformly to both the prepared metal surface and the etched PTFE surface.

For optimal dispersion, brush the adhesive longitudinally on the PTFE and transversely on the metal. The target quantity is approximately 200 grams per square meter of bonding area.

Understanding the Pitfalls and Critical Warnings

The process requires more than just the right materials; it demands a controlled environment to succeed.

The High Risk of On-Site Bonding

Bonding PTFE to metal in the field ("site bonding") is not recommended.

This process is highly sensitive to environmental factors. Achieving a reliable bond requires strictly controlled conditions of cleanliness, temperature, and pressure that are difficult to replicate outside of a workshop environment.

Shear Strength and Bond Integrity

When done correctly, the bond created by the epoxy will be exceptionally strong. The shear value of the epoxy is actually higher than that of the PTFE material itself, ensuring the adhesive joint is not the weakest point in the assembly.

Making the Right Choice for Your Goal

Your approach should be dictated by the level of reliability and performance your project demands.

- If your primary focus is maximum reliability and bond strength: You must use pre-etched PTFE and a two-part epoxy adhesive in a controlled, clean workshop environment.

- If your primary focus is a quick field repair: Be aware that attempting to bond PTFE on-site is extremely high-risk and very likely to fail without specialized preparation and curing equipment.

Ultimately, a successful PTFE-to-metal bond is the result of a precise and disciplined system, not just a single product.

Summary Table:

| Step | Key Action | Critical Detail |

|---|---|---|

| 1. Metal Prep | Roughen & Degrease | Achieve surface roughness (Ra) of 1.6-3 µm |

| 2. PTFE Prep | Use Pre-Etched PTFE | Bond only to the dull, dark brown etched side |

| 3. Adhesive | Apply Two-Part Epoxy | Use a system like Araldite AW 106 / HV 953 U |

| 4. Application | Apply Uniformly | Target 200 g/m², brush longitudinally on PTFE, transversely on metal |

Need a reliable PTFE-to-metal component?

Bonding PTFE in-house is a complex, high-risk process. For maximum reliability and performance, trust the experts at KINTEK.

We specialize in the precision manufacturing and custom fabrication of PTFE components—including seals, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors. Our controlled manufacturing process ensures every bond is strong and durable, eliminating the risk of field failure.

Let us handle the complex bonding for you. Contact KINTEK today to discuss your custom PTFE component needs, from prototypes to high-volume orders.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What are the main applications of PTFE type Teflon? Unlock Its Versatility for Your Industry

- What are the unique properties of PTFE? The 3 Pillars Driving Demand for High-Performance Parts

- What factors should be considered when choosing between Nylon and PTFE? Select the Right Material for Your Application

- What finishing techniques are effective for machined Teflon parts? Achieve Functional Performance and Dimensional Stability

- What chemical processing applications involve PTFE-machined parts? Essential Components for Corrosive & High-Purity Systems