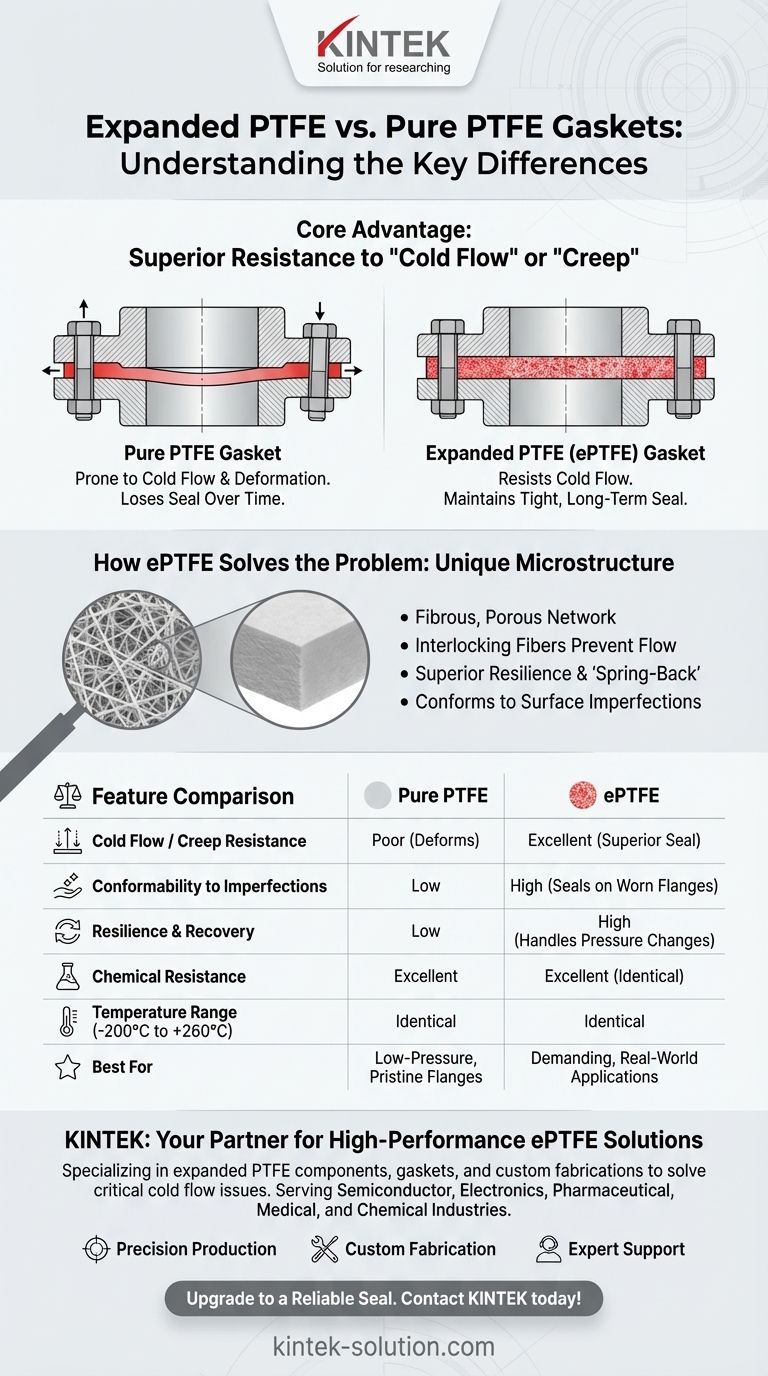

While both gaskets are made from the same base material, the primary advantage of expanded PTFE (ePTFE) is its vastly superior resistance to "cold flow" or "creep." This allows ePTFE to maintain a tight, reliable seal under pressure over long periods, especially on irregular or imperfect surfaces where pure PTFE would deform and fail. This performance difference stems from its unique porous, flexible microstructure.

The core advantage of expanded PTFE is not that it has different chemical properties, but that its specialized physical structure solves the fundamental weakness of pure PTFE. It provides the mechanical resilience and adaptability needed for a durable, real-world seal that pure PTFE's solid structure cannot offer.

The Core Problem with Pure PTFE: Cold Flow

Pure, or "virgin," PTFE is a remarkable material, but its solid structure has one significant mechanical flaw that impacts its performance as a gasket.

What is Cold Flow?

Cold flow, also known as creep, is the tendency of a solid material to slowly deform permanently under persistent mechanical stress.

For a pure PTFE gasket, this means that under the pressure of a bolted flange, the material will gradually "flow" or squeeze out from between the flange faces.

The Consequence for Sealing

This slow deformation causes a loss of the initial bolt torque. As the gasket thins and the bolts loosen, the sealing pressure drops, inevitably leading to leaks over time.

How Expanded PTFE Solves This Problem

Expanded PTFE is manufactured through a process that transforms the solid PTFE into a strong, porous, and highly fibrous microstructure. This structural difference is the key to its superior performance.

A Unique Microstructure

Unlike the solid block of pure PTFE, ePTFE consists of an interconnected web of fibers. This structure gives the material a "sponginess" and resilience that solid PTFE lacks.

Superior Creep Resistance

This fibrous web resists deformation under load. When compressed, the fibers lock together, effectively preventing the material from flowing outwards. This ensures the gasket maintains its thickness and keeps the bolts tight.

Unmatched Conformability

The soft, flexible nature of ePTFE allows it to conform perfectly to microscopic imperfections, scratches, or slight warping on flange surfaces. A rigid, pure PTFE gasket would struggle to seal these minor irregularities.

Enhanced Resilience and Recovery

Expanded PTFE has a degree of "spring-back" or memory. It can adapt to fluctuations in temperature and pressure that might cause a pure PTFE gasket to fail, maintaining a consistent seal as conditions change.

Understanding the Trade-offs

While ePTFE is superior in most demanding applications, it's essential to understand the context of its advantages.

When Pure PTFE is Sufficient

For low-pressure, non-critical applications with perfectly smooth, new, and rigid flange surfaces, a pure PTFE gasket can perform adequately and is often a more economical choice.

Chemical and Thermal Properties Remain Identical

Choosing ePTFE is a mechanical upgrade, not a chemical one. You gain physical durability without sacrificing any of the properties that make PTFE valuable in the first place.

Both gasket types share the same excellent chemical inertness against acids, bases, and solvents, as well as the same wide operational temperature range (-200°C to +260°C).

Practical Installation Advantages

The flexibility of ePTFE gaskets means they are easier to handle and install. They can often be shaped on-site, simplifying inventory and reducing the need for precise pre-cut designs.

Making the Right Choice for Your Application

Your decision should be based on the demands of the specific sealing environment.

- If your primary focus is reliability on older, worn, or slightly misaligned flanges: Expanded PTFE is the definitive choice due to its superior conformability.

- If you need a long-term seal under fluctuating temperatures or pressures: The resilience of ePTFE makes it far more reliable than pure PTFE.

- If you are sealing a high-value or hazardous substance: The superior resistance to cold flow makes ePTFE the safer, more dependable solution.

- If you have a low-pressure, stable application with pristine, new flanges: Pure PTFE may be a sufficient and more economical option.

Ultimately, choosing expanded PTFE is an investment in a more forgiving, durable, and reliable seal that actively compensates for real-world flange imperfections.

Summary Table:

| Feature | Pure PTFE Gasket | Expanded PTFE (ePTFE) Gasket |

|---|---|---|

| Cold Flow / Creep Resistance | Poor (Prone to deformation) | Excellent (Superior long-term seal) |

| Conformability to Surface Imperfections | Low | High (Seals on scratched/warped flanges) |

| Resilience & Recovery | Low | High (Handles pressure/temperature changes) |

| Chemical Resistance | Excellent | Excellent (Identical to pure PTFE) |

| Temperature Range | -200°C to +260°C | -200°C to +260°C (Identical to pure PTFE) |

| Best For | Low-pressure, pristine flange applications | Demanding, real-world sealing applications |

Need a Reliable, Long-Lasting Seal for Demanding Applications?

KINTEK specializes in manufacturing high-performance expanded PTFE (ePTFE) components, including gaskets, seals, and custom fabrications. Our ePTFE products are engineered to solve the critical weakness of cold flow, providing the durable, reliable sealing solution your operations demand.

We serve specialized industries where sealing reliability is critical, including:

- Semiconductor and Electronics Manufacturing

- Pharmaceutical and Medical Equipment

- Laboratory and Analytical Instrumentation

- Chemical Processing and Industrial Applications

Partner with KINTEK for:

- Precision Production: Ensuring consistent quality and performance.

- Custom Fabrication: From prototypes to high-volume orders, tailored to your exact specifications.

- Expert Support: Leverage our material science expertise to select the optimal sealing solution for your unique challenges.

Upgrade to a seal that won't let you down. Contact KINTEK today to discuss your ePTFE gasket and component needs!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What are the limitations of PTFE coated fasteners regarding abrasion resistance? The Trade-Off for Superior Chemical Protection

- What are the advantages of PTFE Liner in terms of weight and noise reduction? Achieve Quieter, Lighter Systems

- What role does PTFE play in industrial equipment maintenance? Extend Lifespan & Reduce Downtime

- What are some specific applications of PTFE gaskets? Sealing Solutions for Harsh Chemical & Thermal Environments

- Why are PTFE washers used in applications requiring low friction? Unlock Superior Performance with KINTEK

- Why are PTFE gaskets considered excellent for electrical insulation? Unmatched Reliability in Harsh Environments

- What do industry experts recommend for optimal sealing with PTFE gaskets? Master the 3-Pillar Strategy

- What alternative material is gaining popularity for hydrogenerator thrust bearings? PTFE for Superior Performance & Reliability