The primary alternative material gaining significant traction for hydrogenerator thrust bearings is Polytetrafluoroethylene, more commonly known as PTFE. This advanced polymer is being adopted for its ability to handle demanding operational conditions far more effectively than traditional materials.

PTFE is not just a substitute for older bearing materials; it represents a fundamental upgrade in hydrogenerator design, enabling higher efficiency and greater resilience, especially during critical system events.

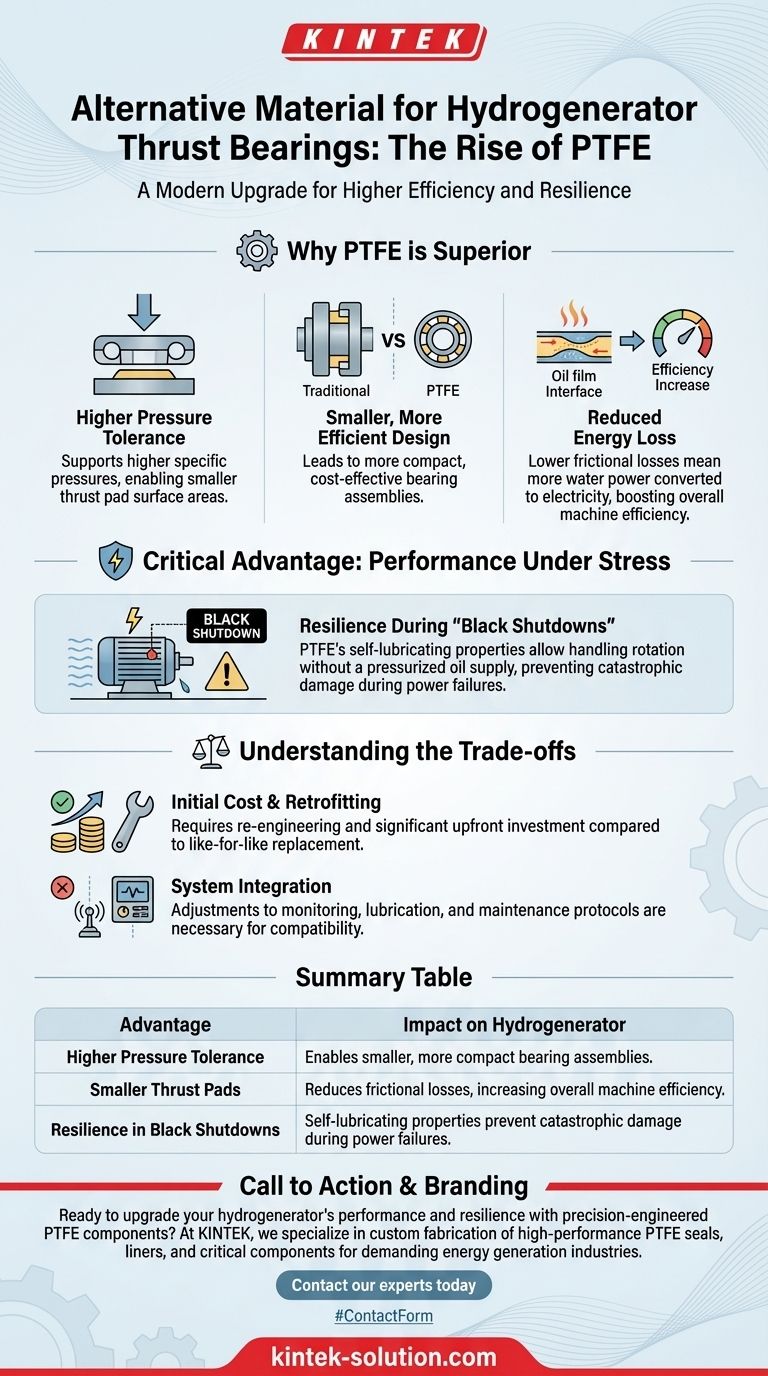

Why PTFE is a Superior Choice for Thrust Bearings

The shift towards PTFE is driven by distinct engineering advantages that directly impact a hydrogenerator's performance and reliability. It addresses long-standing limitations of conventional bearing systems.

Higher Pressure Tolerance

PTFE-faced bearings can withstand significantly higher specific pressures. This core characteristic is the foundation for its other benefits.

This allows engineers to support the same amount of thrust with a smaller surface area, fundamentally changing the design possibilities for the entire bearing assembly.

Smaller, More Efficient Design

The ability to handle more pressure means thrust pads can be made smaller. This reduction in size is a critical design advantage.

Smaller pads lead to a more compact and cost-effective bearing assembly, which can be a significant factor in both new installations and retrofits.

Reduced Energy Loss

The most direct performance benefit of smaller thrust pads is a reduction in frictional losses. Less surface area moving against the oil film means less energy is wasted as heat.

This directly translates to an increase in the overall machine efficiency, allowing the hydrogenerator to convert more water power into electricity.

The Critical Advantage: Performance Under Stress

Beyond baseline efficiency gains, PTFE proves its value most clearly during severe but occasional operational duties. Its properties provide a crucial safety and reliability margin.

Resilience During "Black Shutdowns"

A "black shutdown" occurs when a power failure cuts off the high-pressure oil pumps that normally lubricate the bearings during startup and shutdown.

PTFE bearings are exceptionally well-suited for these events. Their self-lubricating properties and material toughness allow them to handle the rotation without a pressurized oil supply, preventing catastrophic damage that could occur with traditional materials.

Understanding the Trade-offs

While PTFE offers substantial advantages, a complete technical assessment requires considering the full context of its implementation.

Initial Cost and Retrofitting

Adopting PTFE, particularly in an existing facility, is not a simple material swap. It often involves re-engineering the entire thrust bearing assembly to take full advantage of the material's properties.

This can represent a significant upfront investment compared to replacing existing components with like-for-like materials.

System Integration

The unique operating characteristics of PTFE bearings may require adjustments to monitoring and maintenance protocols. The entire lubrication system and its sensors must be compatible with the new design parameters.

Teams must be trained on the specific requirements of PTFE-based systems to ensure long-term reliability.

Making the Right Choice for Your Installation

The decision to use PTFE should be aligned with your primary operational goals for the hydrogenerator.

- If your primary focus is maximizing efficiency: The ability of PTFE to enable smaller thrust pads, which directly reduces energy loss, makes it the superior choice.

- If your primary focus is enhancing reliability and resilience: PTFE's proven capacity to handle severe duties like a black shutdown provides an essential margin of safety for critical installations.

Ultimately, adopting PTFE bearings is a strategic decision to modernize a hydrogenerator for higher performance and greater operational security.

Summary Table:

| Advantage | Impact on Hydrogenerator |

|---|---|

| Higher Pressure Tolerance | Enables smaller, more compact bearing assemblies. |

| Smaller Thrust Pads | Reduces frictional losses, increasing overall machine efficiency. |

| Resilience in Black Shutdowns | Self-lubricating properties prevent catastrophic damage during power failures. |

Ready to upgrade your hydrogenerator's performance and resilience with precision-engineered PTFE components?

At KINTEK, we specialize in the custom fabrication of high-performance PTFE seals, liners, and critical components for demanding industries like energy generation. Our expertise ensures your bearing systems achieve maximum efficiency and operational security.

Contact our experts today to discuss how our PTFE solutions can be tailored to your specific hydrogenerator needs, from prototyping to high-volume production.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What challenges arise when machining PTFE (Teflon)? Overcome Softness, Heat, and Instability

- What finishing techniques are effective for machined Teflon parts? Achieve Functional Performance and Dimensional Stability

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What design considerations are important for custom PTFE parts? Design for Performance & Reliability

- What industrial benefits do PTFE-machined parts offer? Achieve Peak Performance in Demanding Applications