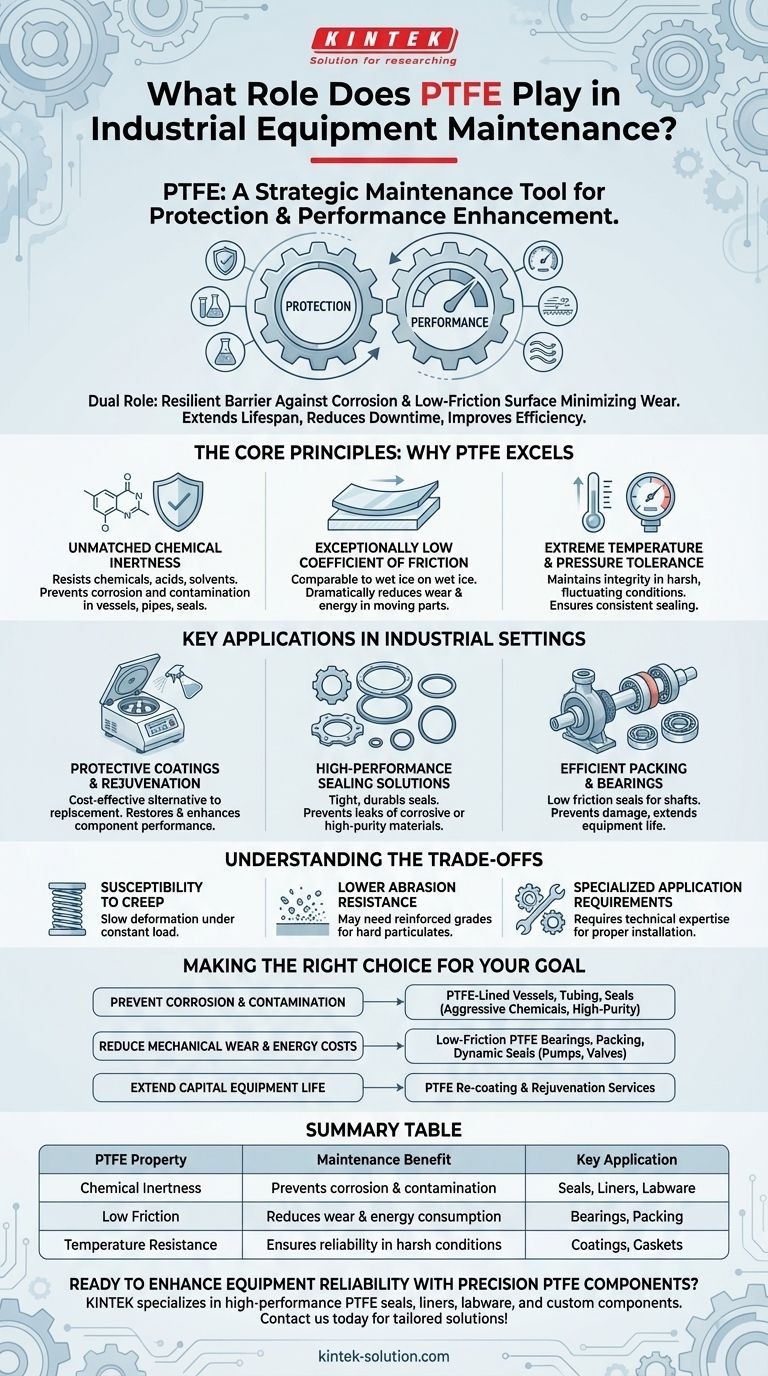

At its core, Polytetrafluoroethylene (PTFE) plays a dual role in industrial maintenance: protection and performance enhancement. It serves as a resilient barrier against chemical corrosion and a low-friction surface that minimizes mechanical wear. By leveraging these properties, maintenance professionals can significantly extend equipment lifespan, reduce operational downtime, and improve overall system efficiency.

The central takeaway is that PTFE is not just a material, but a strategic maintenance tool. Its unique combination of chemical inertness, low friction, and temperature resistance addresses the root causes of many common equipment failures, shifting maintenance from a reactive necessity to a proactive strategy for enhancing reliability.

The Core Principles: Why PTFE Excels in Maintenance

To understand PTFE's role, we must first examine the fundamental properties that make it so effective in demanding industrial environments. These characteristics work in concert to solve multiple maintenance challenges simultaneously.

Unmatched Chemical Inertness

PTFE is renowned for its resistance to nearly all industrial chemicals, acids, and solvents. This inertness is critical for preventing corrosion.

By lining vessels, pipes, and containers or by being used in seals, PTFE ensures that reactive substances do not degrade the underlying equipment. This also prevents contamination of the process fluid, which is vital in pharmaceutical and laboratory settings.

Exceptionally Low Coefficient of Friction

PTFE has one of the lowest coefficients of friction of any solid material, comparable to wet ice on wet ice. This property is a game-changer for moving parts.

In applications like bearings, seals, and packing for pumps and valves, this low friction dramatically reduces wear and tear. It also lowers the energy required to operate the equipment, leading to direct cost savings.

Extreme Temperature and Pressure Tolerance

PTFE maintains its integrity across a wide range of temperatures and pressures. This stability makes it a reliable choice for components operating in harsh or fluctuating conditions.

Its ability to perform without degrading ensures consistent sealing and performance, reducing the risk of failure in critical systems.

Key Applications in Industrial Settings

These core properties translate into several high-impact applications that are central to modern industrial maintenance and reliability programs.

Protective Coatings and Rejuvenation

One of PTFE's most direct maintenance roles is in the rejuvenation of critical equipment. Components like industrial centrifuges can be stripped of their old surfaces and re-coated with PTFE.

This process not only restores the component to its original specifications but often enhances its performance. It is a cost-effective alternative to full replacement that minimizes production downtime and extends the asset's service life.

High-Performance Sealing Solutions

PTFE is a premier material for gaskets, O-rings, and seals. Its ability to create a tight, durable seal prevents leaks of corrosive, hazardous, or high-purity materials.

Because it resists chemical attack and temperature degradation, PTFE seals last longer than those made from many other materials. This directly reduces the frequency of maintenance interventions needed to replace failed seals.

Efficient Packing and Bearings

In rotating equipment like pumps and mixers, PTFE packing is used to seal shafts. Its low-friction nature prevents damage to the shaft while providing a reliable seal, extending the life of both the packing and the equipment itself.

Reinforced versions, blended with materials like aramid or graphite, offer enhanced durability for particularly abrasive or high-pressure applications, further improving reliability.

Understanding the Trade-offs

While highly effective, PTFE is not a universal solution. An objective assessment requires acknowledging its limitations to ensure it is applied correctly.

Susceptibility to Creep

PTFE is a relatively soft material and can be subject to "creep," or slow deformation, when placed under a constant load, especially at elevated temperatures. This must be accounted for in the design of high-pressure seals and gaskets.

Lower Abrasion Resistance

Compared to metals or hard ceramics, pure PTFE can be susceptible to wear from abrasive particles. In environments with hard particulates, reinforced PTFE grades are often necessary to provide the required durability.

Specialized Application Requirements

Applying a high-performance PTFE coating or selecting the correct seal geometry is not always straightforward. It requires technical expertise to ensure proper surface preparation and installation, without which the full benefits may not be realized.

Making the Right Choice for Your Goal

To apply this knowledge effectively, align the properties of PTFE with your specific maintenance objective.

- If your primary focus is preventing corrosion and contamination: Utilize PTFE-lined vessels, tubing, and seals, especially when handling aggressive chemicals or in high-purity applications.

- If your primary focus is reducing mechanical wear and energy costs: Implement low-friction PTFE bearings, packing, and dynamic seals in pumps, valves, and other rotating equipment.

- If your primary focus is extending the life of capital equipment: Explore PTFE re-coating and rejuvenation services as a cost-effective alternative to replacing large, worn-out components.

Ultimately, integrating PTFE into your maintenance strategy is a proactive measure to enhance equipment reliability, safety, and operational efficiency.

Summary Table:

| PTFE Property | Maintenance Benefit | Key Application |

|---|---|---|

| Chemical Inertness | Prevents corrosion & contamination | Seals, Liners, Labware |

| Low Friction | Reduces wear & energy consumption | Bearings, Packing |

| Temperature Resistance | Ensures reliability in harsh conditions | Coatings, Gaskets |

Ready to enhance your equipment reliability with precision PTFE components?

KINTEK specializes in manufacturing high-performance PTFE seals, liners, labware, and custom components for the semiconductor, medical, laboratory, and industrial sectors. Our expertise in precision production and custom fabrication—from prototypes to high-volume orders—ensures you get solutions tailored to your specific maintenance challenges.

Contact us today to discuss how our PTFE products can extend your equipment's lifespan and reduce operational downtime!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs