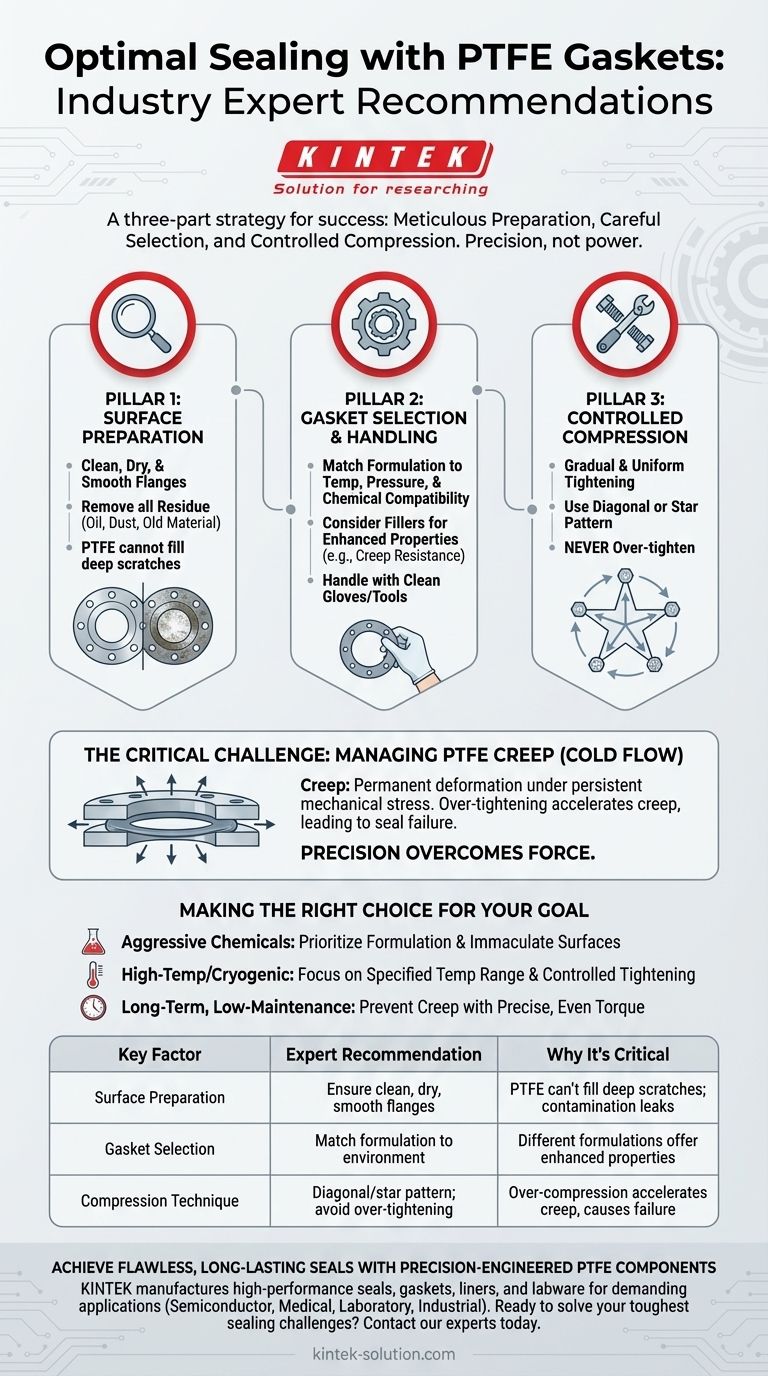

For optimal sealing with PTFE gaskets, industry experts universally recommend a three-part strategy. Success depends on meticulous flange surface preparation, the careful selection of the correct gasket formulation for the specific application, and a controlled, uniform bolt tightening procedure to apply even compression.

The core challenge with PTFE is managing its unique properties. While it offers unparalleled chemical and thermal resistance, its tendency to "creep" or cold flow under pressure means that brute force is counterproductive. A successful seal relies on precision, not power.

The Three Pillars of an Effective PTFE Seal

Achieving a durable, leak-free seal with PTFE is a systematic process. Each of the following steps is critical to counter the material's inherent properties and leverage its strengths.

Pillar 1: Flange Surface Preparation

A pristine sealing surface is non-negotiable. PTFE is a soft material that conforms well to surfaces, but it cannot fill deep scratches or overcome contamination.

Flanges must be perfectly clean, dry, and smooth. Any residue, such as oils from hands, dust, or old gasket material, can create a leak path and must be completely removed.

Pillar 2: Gasket Selection and Handling

Not all PTFE gaskets are the same. The formulation must match the demands of the environment.

Consider the application's specific temperature, pressure, and chemical compatibility requirements. Various fillers can be added to PTFE to enhance its properties, such as resistance to creep.

Handle the gasket with clean gloves or tools. Scratches or contamination from bare hands can compromise the sealing surface and lead to premature failure.

Pillar 3: Controlled and Uniform Compression

This is the most critical phase where PTFE's unique nature comes into play. The goal is to achieve a sufficient seal without over-compressing the material.

Bolts must be tightened gradually and evenly. Use a diagonal or star pattern to distribute the load uniformly across the flange face.

Never over-tighten the bolts. Excessive force will cause the PTFE to creep, leading to a loss of bolt load over time and an eventual leak.

The Critical Challenge: Managing PTFE Creep

Understanding the primary limitation of PTFE is essential for anyone aiming to create a reliable seal. Its greatest weakness is its tendency to creep.

What is Creep (Cold Flow)?

Creep, or cold flow, is the tendency of a solid material to deform permanently under the influence of persistent mechanical stress.

For a PTFE gasket, this means the material will slowly "flow" away from the high-pressure points under the flange. This process reduces the gasket's thickness, which in turn reduces the bolt load and the sealing pressure.

Why Precision Overcomes Force

The common instinct to simply tighten a leaking flange further is counterproductive with PTFE.

Applying excessive torque accelerates creep, permanently deforming the gasket and guaranteeing a future leak. The key is to apply just enough, and just the right amount of, uniform pressure to create an initial seal.

Making the Right Choice for Your Goal

Your specific objective will determine which aspect of the installation process requires the most attention.

- If your primary focus is containing aggressive chemicals: Prioritize selecting the correct PTFE formulation and ensuring immaculate flange surfaces to prevent any potential leak paths.

- If you are working with high-temperature or cryogenic applications: Verify the gasket's specified temperature range and focus on a controlled tightening procedure to manage material expansion and contraction.

- If your priority is a long-term, low-maintenance seal: The single most important factor is preventing creep by applying precise, even bolt torque and resisting the urge to over-compress.

By respecting the unique properties of PTFE through precise installation, you can achieve a seal that is virtually indestructible.

Summary Table:

| Key Factor | Expert Recommendation | Why It's Critical |

|---|---|---|

| Surface Preparation | Ensure flanges are clean, dry, and smooth. | PTFE cannot fill deep scratches; contamination creates leak paths. |

| Gasket Selection | Match PTFE formulation (e.g., filled vs. virgin) to temperature, pressure, and chemical exposure. | Different formulations offer enhanced properties like improved creep resistance. |

| Compression Technique | Use a diagonal/star pattern for uniform bolt tightening; avoid over-tightening. | Over-compression accelerates PTFE creep (cold flow), leading to seal failure. |

Achieve Flawless, Long-Lasting Seals with Precision-Engineered PTFE Components

Mastering the three pillars of PTFE sealing is essential for reliability in demanding applications. At KINTEK, we manufacture high-performance PTFE seals, gaskets, liners, and labware designed to excel in the most challenging environments, including semiconductor, medical, laboratory, and industrial processes.

Our expertise ensures every component is precision-engineered to mitigate challenges like creep, providing the durability and chemical resistance your operations demand. Whether you need a custom prototype or high-volume production, we deliver solutions tailored to your exact specifications.

Ready to solve your toughest sealing challenges? Contact our experts today to discuss your application and receive a custom solution quote.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Bottles for Diverse Industrial Applications

People Also Ask

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech