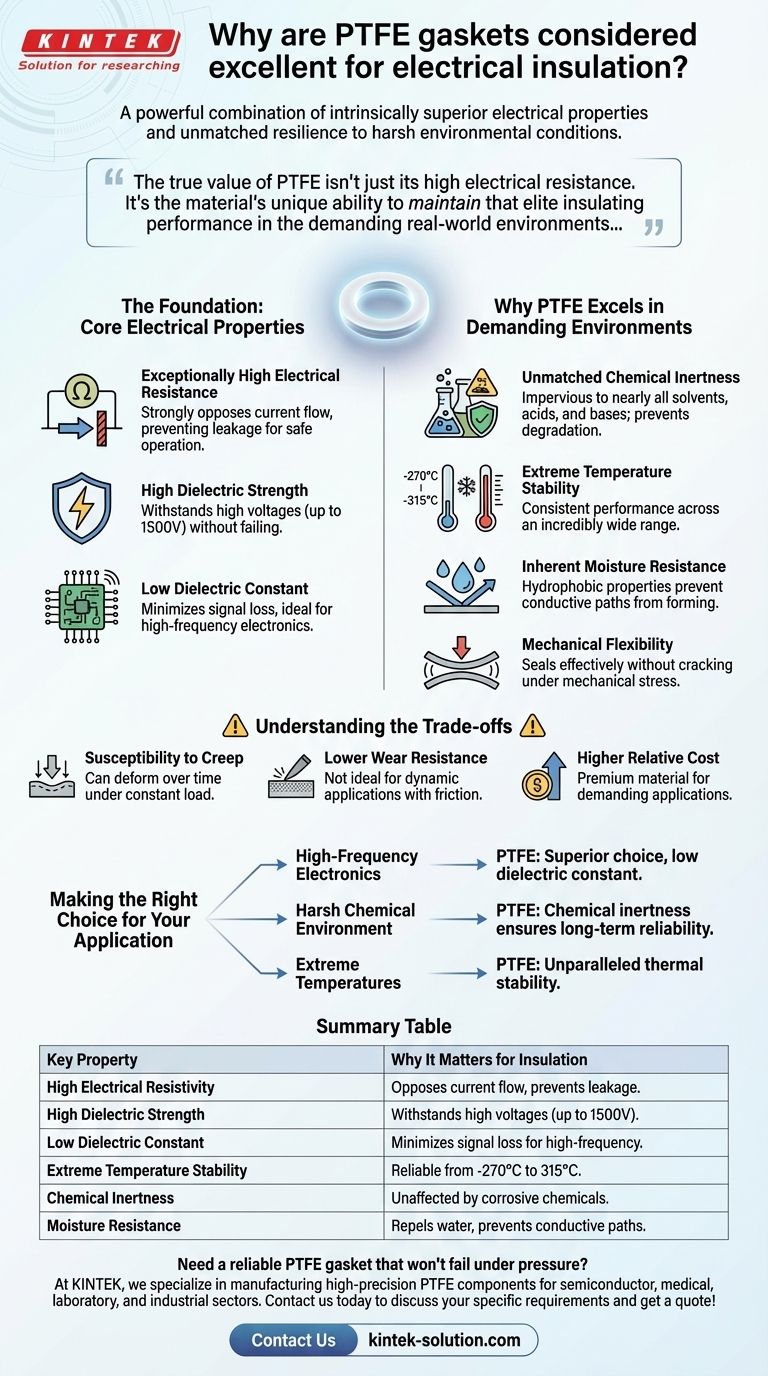

To put it simply, PTFE gaskets are considered excellent for electrical insulation because of a powerful combination of intrinsically superior electrical properties and an unmatched resilience to harsh environmental conditions. They don't just block electrical current effectively; they continue to do so reliably under extreme temperatures, chemical exposure, and mechanical stress.

The true value of PTFE isn't just its high electrical resistance. It's the material's unique ability to maintain that elite insulating performance in the demanding real-world environments where gaskets are required to function without fail.

The Foundation: Core Electrical Properties

At its core, Polytetrafluoroethylene (PTFE) has a molecular structure that makes it an almost perfect electrical insulator. This is defined by several key metrics.

Exceptionally High Electrical Resistance

PTFE exhibits extremely high electrical resistivity. This means it strongly opposes the flow of electric current, preventing leakage and ensuring that electricity stays on its intended path.

This property is fundamental to protecting sensitive electronic components and ensuring the safe operation of electrical equipment.

High Dielectric Strength

Dielectric strength measures a material's ability to withstand a strong electric field without breaking down and becoming conductive.

PTFE has a very high dielectric strength, capable of resisting high voltages (up to 1500 volts) without failing. This makes it ideal for insulating high-voltage wires, cables, and connectors.

Low Dielectric Constant

A low dielectric constant means the material stores very little electrical energy when subjected to an electric field.

This is a critical advantage in high-frequency applications, such as in circuit boards and communication cables, as it minimizes signal loss and ensures signal integrity.

Why PTFE Excels in Demanding Environments

An insulator is only as good as its ability to perform under real-world stress. This is where PTFE's robust physical properties set it apart from other materials.

Unmatched Chemical Inertness

PTFE is famously inert and impervious to nearly all solvents, acids, and bases. This means that corrosive chemicals in the operating environment will not degrade the gasket or compromise its insulating capabilities over time.

Extreme Temperature Stability

PTFE maintains its excellent electrical and physical properties across an incredibly wide temperature range, from -454°F to 600°F (-270°C to 315°C).

Unlike other plastics that can become brittle or melt, PTFE's performance remains consistent, making it a reliable choice for applications with significant temperature fluctuations.

Inherent Moisture Resistance

PTFE is hydrophobic, meaning it repels water. This prevents moisture from being absorbed into the gasket, which could otherwise create a conductive path and lead to electrical failure.

Mechanical Flexibility

The carbon-fluorine bonds that give PTFE its stability also provide a degree of flexibility. This ensures the gasket can seal effectively without cracking under the mechanical stress of compression, protecting the electrical components within.

Understanding the Trade-offs

While PTFE is an elite performer, no material is perfect for every situation. Objectivity requires acknowledging its limitations.

Susceptibility to Creep

PTFE can be prone to "creep" or "cold flow," meaning it can slowly deform over time when under a constant compressive load. This must be considered in high-pressure sealing applications.

Lower Wear Resistance

As a relatively soft material, PTFE has lower resistance to abrasion and wear compared to harder engineering plastics. It may not be suitable for dynamic applications involving friction.

Higher Relative Cost

PTFE is a premium performance material, and its cost generally reflects that. For less demanding applications where the environment is stable, other less expensive insulators may suffice.

Making the Right Choice for Your Application

Selecting the right material depends entirely on the demands of your specific project.

- If your primary focus is high-frequency electronics: PTFE is the superior choice due to its low dielectric constant, which prevents signal degradation.

- If your primary focus is reliability in a harsh chemical environment: PTFE's chemical inertness ensures the insulator will not degrade, providing long-term safety and performance.

- If your primary focus is performance across extreme temperatures: PTFE's unparalleled thermal stability makes it one of the only viable options.

Ultimately, choosing a PTFE gasket is an investment in unwavering reliability where electrical insulation cannot be compromised.

Summary Table:

| Key Property | Why It Matters for Insulation |

|---|---|

| High Electrical Resistivity | Strongly opposes current flow, preventing leakage and protecting components. |

| High Dielectric Strength | Withstands high voltages (up to 1500V) without failing. |

| Low Dielectric Constant | Minimizes signal loss, ideal for high-frequency electronics. |

| Extreme Temperature Stability | Performs reliably from -270°C to 315°C. |

| Chemical Inertness | Unaffected by corrosive chemicals, ensuring long-term performance. |

| Moisture Resistance | Repels water to prevent conductive paths and failure. |

Need a reliable PTFE gasket that won't fail under pressure?

At KINTEK, we specialize in manufacturing high-precision PTFE components, including seals, liners, and labware, for the semiconductor, medical, laboratory, and industrial sectors. Our expertise ensures your electrical insulation is protected against extreme temperatures, harsh chemicals, and mechanical stress.

We offer custom fabrication from prototypes to high-volume orders, prioritizing precision and reliability for your most demanding applications.

Contact us today to discuss your specific requirements and get a quote!

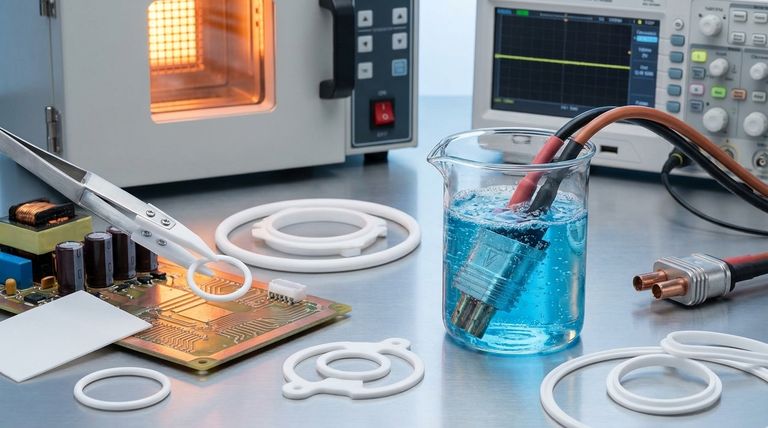

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What challenges arise when machining PTFE (Teflon)? Overcome Softness, Heat, and Instability

- What industrial benefits do PTFE-machined parts offer? Achieve Peak Performance in Demanding Applications

- What factors should be considered when choosing between Nylon and PTFE? Select the Right Material for Your Application

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What chemical processing applications involve PTFE-machined parts? Essential Components for Corrosive & High-Purity Systems