At its core, Polytetrafluoroethylene (PTFE) washers are used in low-friction applications because PTFE has a lower coefficient of friction than any other known solid material. This unique molecular property allows moving parts to slide against each other with minimal resistance, effectively serving as a solid, self-lubricating surface where traditional oils or greases are impractical.

The true value of PTFE in engineering is not just its remarkable "slipperiness," but the powerful combination of this low-friction characteristic with its exceptional chemical inertness, wide temperature tolerance, and excellent electrical insulation.

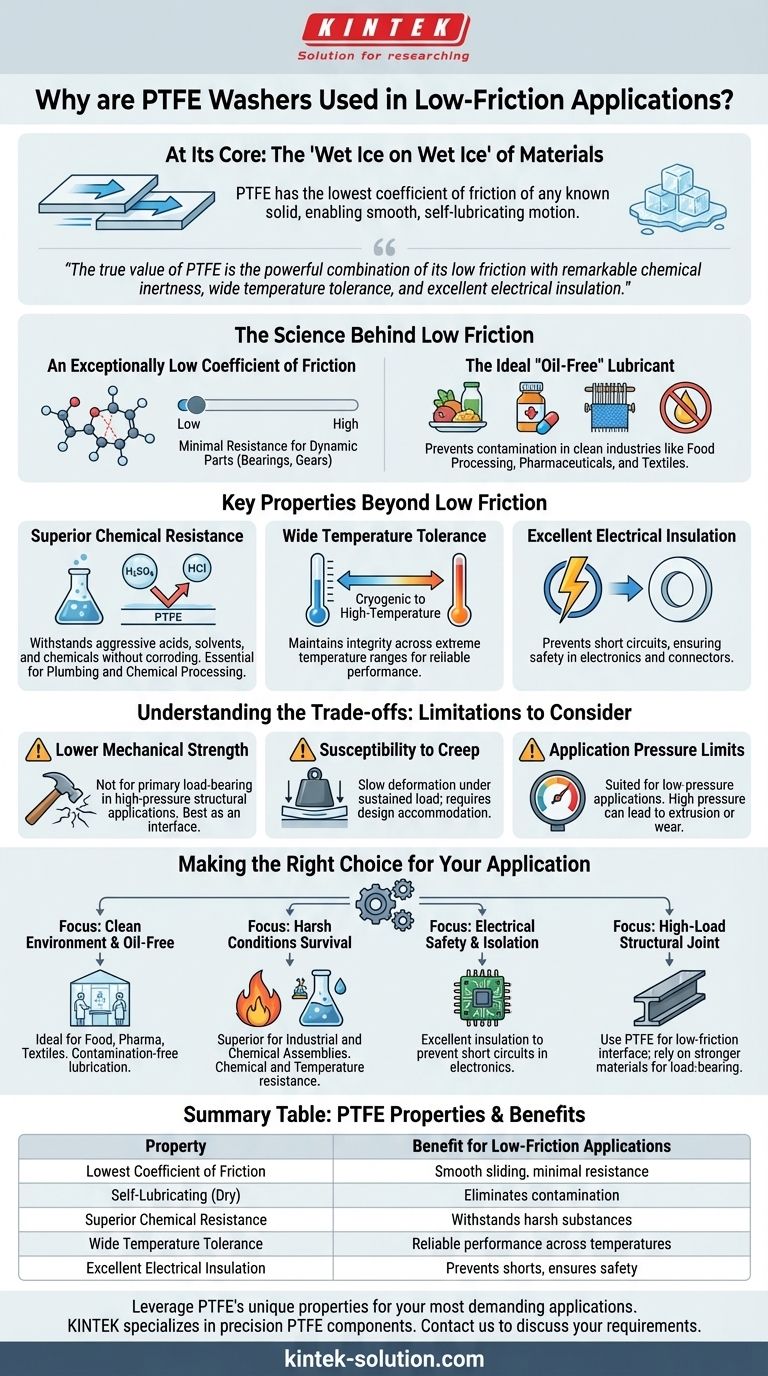

The Science Behind PTFE's Low Friction

The fundamental reason PTFE is chosen for these applications lies in its unique molecular structure, which results in an incredibly low surface energy.

An Exceptionally Low Coefficient of Friction

PTFE's coefficient of friction is famously low, often compared to that of wet ice on wet ice. This means that the force required to move one PTFE surface over another is incredibly small.

This property is invaluable in dynamic applications like bearings, gears, and sliding plates, where minimizing frictional losses is critical for efficiency and longevity.

The Ideal 'Oil-Free' Lubricant

In many industries, liquid lubricants are a source of contamination. In food processing, pharmaceuticals, or textile manufacturing, a stray drop of oil can ruin a product batch.

PTFE provides a solution by acting as a dry lubricant. It allows mechanical parts like piston rings and machine tool guides to operate smoothly without introducing any foreign liquid substances.

Key Properties Beyond Low Friction

While low friction is the headline feature, PTFE's utility is magnified by a set of other elite properties that allow it to perform in environments where other materials would fail.

Superior Chemical Resistance

PTFE is composed of inert materials, making it almost universally resistant to chemicals, acids, and solvents.

This makes PTFE washers essential in plumbing and chemical processing equipment, where they will not corrode or degrade when exposed to aggressive substances.

Wide Temperature Tolerance

PTFE maintains its integrity and properties across an exceptionally broad temperature range. This makes it a reliable choice for components used in both cryogenic and high-temperature machinery.

Excellent Electrical Insulation

PTFE is a superb electrical insulator, meaning it does not conduct electricity.

This property is critical in electronics and electrical equipment, where PTFE washers are used to isolate components, prevent short circuits, and ensure safety and performance in connectors and terminals.

Understanding the Trade-offs

No material is perfect for every situation. Being a trusted advisor means acknowledging a material's limitations to ensure it is used correctly.

Lower Mechanical Strength

Compared to metals or harder plastics, PTFE is a relatively soft material. It is not designed to be a primary load-bearing component in high-pressure structural applications.

Its strength lies in providing a low-friction interface between two harder components, such as distributing the load of a screw head without damaging a delicate surface.

Susceptibility to Creep

Under a constant, sustained load, PTFE can slowly deform over time. This phenomenon, known as "creep," must be accounted for in any design where a washer is placed under long-term compressive stress.

Application Pressure Limits

As noted for related components like O-rings, PTFE is often best suited for low-pressure applications. In high-pressure dynamic systems, its softness can lead to extrusion or premature wear if not properly supported.

Making the Right Choice for Your Application

To select the right material, you must align its properties with your primary engineering goal.

- If your primary focus is reducing friction in a clean environment: PTFE is an ideal choice for oil-free lubrication in industries like food processing, pharmaceuticals, or textiles.

- If your primary focus is component survival in harsh conditions: PTFE's combined resistance to extreme temperatures and aggressive chemicals makes it a superior choice for industrial and chemical processing assemblies.

- If your primary focus is electrical safety and isolation: A PTFE washer provides excellent insulation to prevent short circuits and enhance performance in electronic components.

- If your primary focus is a high-load structural joint: Use PTFE to create a low-friction or protective interface, but rely on stronger materials like steel for the primary load-bearing task.

Understanding these distinct advantages and limitations allows you to leverage PTFE not just as a component, but as a precise engineering solution.

Summary Table:

| Property | Benefit for Low-Friction Applications |

|---|---|

| Lowest Coefficient of Friction | Enables smooth sliding with minimal resistance, ideal for bearings and guides. |

| Self-Lubricating (Dry) | Eliminates oil/grease contamination, perfect for food, pharma, and cleanrooms. |

| Superior Chemical Resistance | Withstands harsh acids and solvents without degrading. |

| Wide Temperature Tolerance | Performs reliably from cryogenic to high-temperature settings. |

| Excellent Electrical Insulation | Prevents short circuits and ensures safety in electronic components. |

Leverage PTFE's unique properties for your most demanding applications. KINTEK specializes in manufacturing precision PTFE components—including seals, liners, and custom labware—for the semiconductor, medical, laboratory, and industrial sectors. Whether you need prototypes or high-volume orders, our expertise ensures a solution that enhances efficiency, reliability, and cleanliness. Contact KINTEK today to discuss your specific requirements and get a quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Bottles for Diverse Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- What is PTFE commonly known as and what are its unique properties? Unlock Unmatched Chemical & Thermal Resistance

- What is the working temperature range of PTFE? Master Extreme Heat and Cryogenic Applications

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What are the material advantages of machining Teflon? Unlock Unmatched Chemical & Thermal Resistance

- What are the key benefits of PTFE in custom fabrication? Unlock Performance in Extreme Conditions