At its core, a PTFE liner reduces weight and noise by substituting dense metals with a lightweight polymer and leveraging its exceptionally low friction to allow components to glide silently past one another. This unique combination of properties makes it a critical material in modern engineering, where efficiency and performance are paramount.

The decision to use a PTFE liner is about more than just its immediate benefits. It represents a strategic choice to enhance overall system efficiency by reducing mass, minimizing friction-induced energy loss, and increasing component longevity in demanding environments.

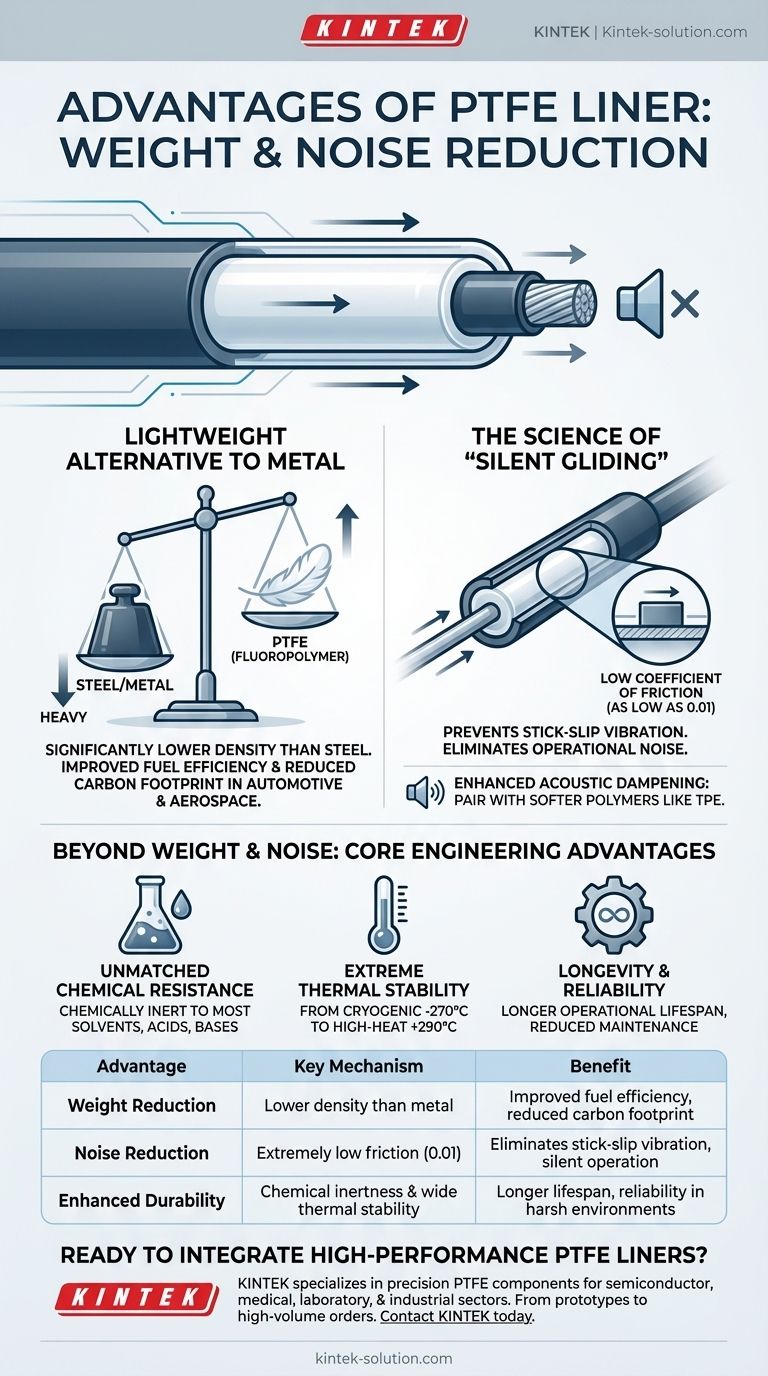

The Mechanics of Weight and Noise Reduction

To understand the advantages of PTFE, we must look at its fundamental material properties. The benefits are not incidental; they are a direct result of its molecular structure.

A Lightweight Alternative to Metal

PTFE is a fluoropolymer—a type of plastic. Its inherent density is significantly lower than that of conventional materials like steel, which are often used for protective wraps or conduits.

This direct mass reduction is critical in applications like automotive and aerospace, where lighter components contribute directly to improved fuel efficiency and a reduced carbon footprint.

The Science of "Silent Gliding"

The defining characteristic of PTFE is its extremely low coefficient of friction (with a dynamic value as low as 0.01). It is one of the most slippery materials known.

This property allows components, such as cable wires, to move inside the liner with virtually no resistance. This smooth gliding action prevents the stick-slip vibration that is a common source of operational noise in mechanical systems.

Enhanced Acoustic Dampening

For applications requiring even greater noise suppression, PTFE liners can be engineered within a multi-material system.

Pairing a PTFE inner layer with an outer jacket made of a softer polymer, like TPE (Thermoplastic Elastomer), can further absorb and minimize the transmission of sound, creating a comprehensively quiet solution.

Beyond Weight and Noise: Core Engineering Advantages

While the initial query focuses on weight and noise, the true value of PTFE is realized when considering its other elite properties. These characteristics ensure that the liner not only performs its primary function but also enhances the durability and reliability of the entire assembly.

Unmatched Chemical Resistance

PTFE is chemically inert to nearly all industrial solvents, acids, and bases. This makes it an ideal choice for applications where components are exposed to corrosive fluids or harsh cleaning agents, preventing material degradation over time.

Extreme Thermal Stability

The material maintains its integrity and properties across an exceptionally wide temperature range, performing reliably from cryogenic conditions (-270°C) up to high-heat environments (+290°C). This stability ensures predictable performance where other materials would fail.

Longevity and System Reliability

The combination of chemical, thermal, and frictional resistance means PTFE components do not degrade easily. This leads to a longer operational lifespan, reducing the frequency of maintenance and replacement, which in turn improves overall industrial efficiency.

Understanding the Trade-offs

No material is perfect for every scenario. An objective assessment requires acknowledging PTFE's limitations to ensure it is deployed correctly.

Mechanical Strength Considerations

While durable, PTFE is a polymer, not a metal. It does not possess the high tensile strength or rigidity of steel. For this reason, it is most often used as a liner or coating inside a more structural component, leveraging its surface properties without relying on it for load-bearing capacity.

Radiation Sensitivity

The references note a radiation resistance of up to 0.02 Mrad. In the context of material science, this is a relatively low threshold. For applications involving significant radiation exposure, such as in the nuclear industry or certain space environments, specialized or alternative materials would be necessary.

Cost vs. Lifecycle Value

PTFE is one of the more affordable fluoropolymers, but it is typically more expensive than commodity plastics or raw steel. The investment must be weighed against the total lifecycle value, which includes gains from lower energy consumption, reduced maintenance, and superior reliability in harsh conditions.

Making the Right Choice for Your Application

Selecting the right material depends entirely on your primary engineering goal.

- If your primary focus is maximum weight reduction and fuel efficiency: PTFE is an outstanding choice to replace heavier steel components, particularly in automotive and aerospace applications.

- If your primary focus is eliminating operational noise and vibration: The ultra-low friction of a PTFE liner is its key advantage for robotics, precision machinery, and medical devices.

- If your primary focus is reliability in harsh environments: PTFE's unparalleled chemical and thermal resistance ensures component longevity in chemical processing and demanding industrial operations.

Ultimately, understanding the complete profile of PTFE allows you to leverage it not just as a component, but as a tool for creating more efficient, durable, and reliable systems.

Summary Table:

| Advantage | Key Mechanism | Benefit |

|---|---|---|

| Weight Reduction | Lower density than metal | Improved fuel efficiency, reduced carbon footprint |

| Noise Reduction | Extremely low coefficient of friction (as low as 0.01) | Eliminates stick-slip vibration, silent operation |

| Enhanced Durability | Chemical inertness & wide thermal stability (-270°C to +290°C) | Longer lifespan, reliability in harsh environments |

Ready to integrate high-performance PTFE liners into your designs?

KINTEK specializes in manufacturing precision PTFE components—including seals, liners, and custom labware—for the semiconductor, medical, laboratory, and industrial sectors. Our expertise ensures your systems benefit from reduced weight, minimal noise, and superior chemical resistance, leading to greater efficiency and reliability.

We offer custom fabrication from prototypes to high-volume orders. Contact KINTEK today to discuss your specific requirements and leverage our material science expertise for your next project.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

People Also Ask

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials