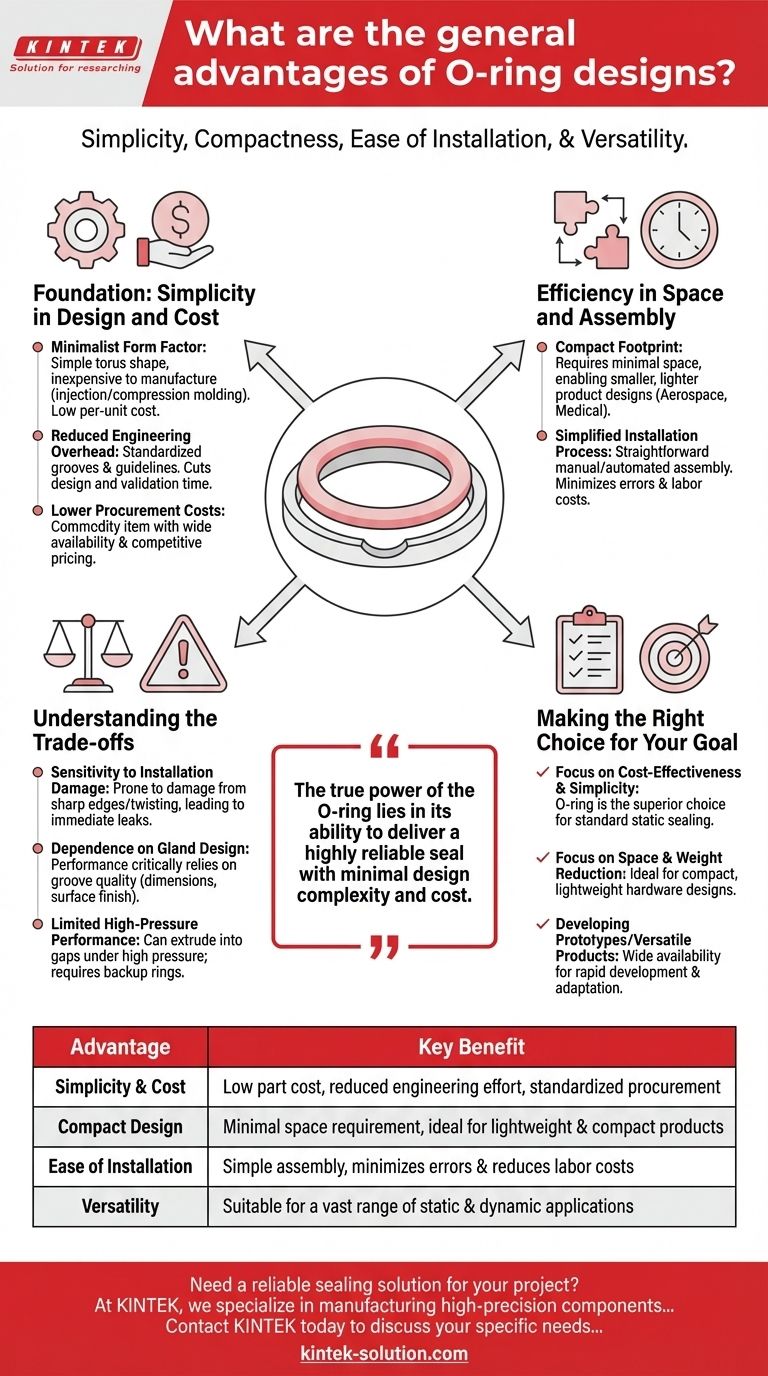

At its core, the O-ring's primary advantages are its profound simplicity, compact design, ease of installation, and remarkable versatility. This combination makes it one of the most reliable and cost-effective sealing solutions available for an enormous range of industrial and commercial applications.

The true power of the O-ring lies in its ability to deliver a highly reliable seal with minimal design complexity and cost. This balance makes it the default engineering choice for a vast number of static and dynamic applications.

The Foundation: Simplicity in Design and Cost

The most significant advantage of an O-ring is its fundamental simplicity. This single characteristic is the source of many of its other benefits, particularly related to cost and engineering effort.

Minimalist Form Factor

An O-ring is a simple torus, or doughnut shape. This geometry is easy and inexpensive to manufacture through processes like injection or compression molding.

Its basic shape requires minimal material, keeping the per-unit cost extremely low, especially at high production volumes.

Reduced Engineering Overhead

Designing a groove for an O-ring is a well-understood and standardized process. Engineers can rely on established guidelines for dimensions and tolerances, drastically reducing design and validation time.

This contrasts sharply with custom gaskets or complex sealing systems that require significant bespoke engineering effort.

Lower Procurement Costs

Due to standardization, O-rings are a commodity item. They are widely available from numerous suppliers in standard sizes and materials, which fosters competitive pricing and ensures supply chain stability.

Efficiency in Space and Assembly

Beyond low cost, the O-ring's design delivers tangible benefits in the physical product by saving space and simplifying the manufacturing process.

Compact Footprint

O-rings require very little physical space. The groove they sit in is only slightly larger than the O-ring itself, allowing for smaller, lighter, and more compact product designs.

This is a critical advantage in applications where space and weight are at a premium, such as in aerospace, medical devices, and consumer electronics.

Simplified Installation Process

Installing an O-ring is typically a straightforward manual or automated process that does not require special tools or extensive training.

This ease of assembly minimizes the risk of installation errors, which are a common cause of seal failure. It also reduces labor costs and speeds up production lines.

Understanding the Trade-offs

While highly effective, the O-ring is not a universal solution. An objective assessment requires understanding its limitations.

Sensitivity to Installation Damage

Although installation is simple, it must be done carefully. An O-ring can be easily damaged by sharp edges or twisting during assembly, creating a leak path that compromises the seal immediately.

Dependence on Gland Design

The O-ring's performance is entirely dependent on the quality of the groove (gland) it sits in. An improperly machined gland with incorrect dimensions or a poor surface finish will prevent the O-ring from sealing effectively, regardless of its own quality.

Limited High-Pressure Performance

In high-pressure applications, a standard O-ring can be forced into the gap between mating surfaces, a failure mode known as extrusion. This can be mitigated with backup rings but adds complexity to the design.

Making the Right Choice for Your Goal

An O-ring should be considered the baseline for most sealing needs. Use the following guidelines to determine if it aligns with your project's priorities.

- If your primary focus is cost-effectiveness and simplicity: The O-ring is almost always the superior choice for standard static sealing applications due to its low part cost and minimal design overhead.

- If your primary focus is space and weight reduction: The O-ring's minimal footprint allows for more compact and lightweight hardware designs compared to bulkier gasket solutions.

- If you are developing a prototype or a versatile product line: The wide availability of standard sizes and materials makes the O-ring an ideal component for rapid development and adaptation to various operating conditions.

Ultimately, the O-ring's enduring popularity stems from its ability to provide a robust, reliable seal with unmatched economic efficiency.

Summary Table:

| Advantage | Key Benefit |

|---|---|

| Simplicity & Cost | Low part cost, reduced engineering effort, standardized procurement |

| Compact Design | Minimal space requirement, ideal for lightweight and compact products |

| Ease of Installation | Simple assembly, minimizes errors and reduces labor costs |

| Versatility | Suitable for a vast range of static and dynamic applications |

Need a reliable sealing solution for your project?

At KINTEK, we specialize in manufacturing high-precision components, including custom seals and advanced polymer parts, for the semiconductor, medical, laboratory, and industrial sectors. Our expertise in custom fabrication—from prototypes to high-volume orders—ensures you get a sealing solution that perfectly matches your application's requirements for performance, durability, and cost-effectiveness.

Contact KINTEK today to discuss your specific needs and discover how our precision components can enhance your product's reliability.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers