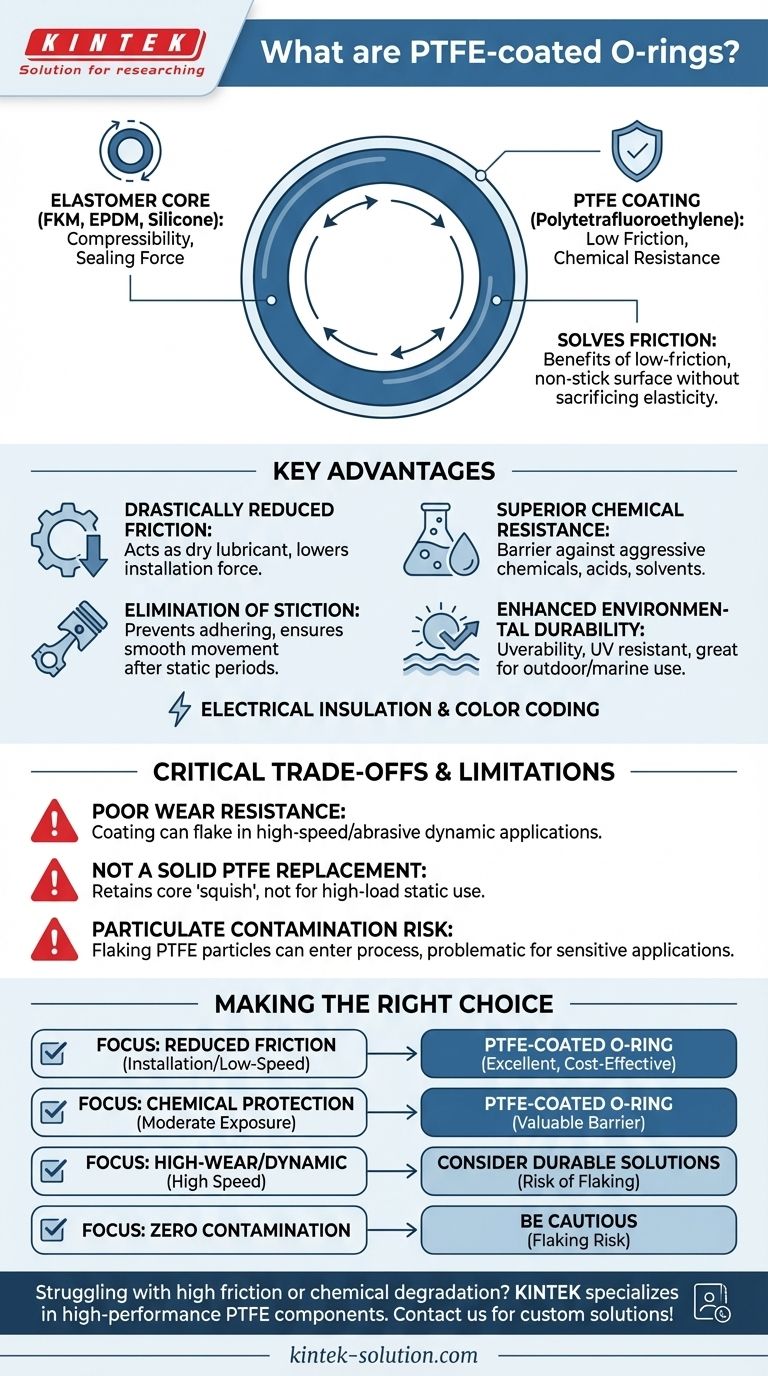

In essence, a PTFE-coated O-ring is a standard elastomeric O-ring (often made of materials like FKM, EPDM, or Silicone) encapsulated in a thin layer of Polytetrafluoroethylene (PTFE). This design combines the flexibility and sealing capability of the rubber core with the unique surface properties of PTFE, such as extremely low friction and high chemical resistance.

The core problem a PTFE-coated O-ring solves is friction. It allows you to gain the benefits of a low-friction, non-stick surface without sacrificing the essential compressibility and elasticity of a standard rubber O-ring.

The Best of Both Worlds: Core vs. Coating

To understand the value of this component, you must think of it as a hybrid solution that leverages two different materials to achieve a single goal.

The Elastomer Core: The Engine of the Seal

The inner O-ring provides the fundamental sealing force. Its elastomeric properties allow it to compress, conform to surface imperfections, and rebound, maintaining a tight seal against pressure.

The PTFE Coating: The Protective Shield

The thin outer coating doesn't provide the primary sealing function. Instead, it acts as a functional surface that enhances the performance of the core material in specific ways.

Key Advantages of a PTFE Coating

Applying a PTFE layer addresses several common challenges found in sealing applications, making it a valuable problem-solving tool.

Drastically Reduced Friction

PTFE has an extremely low coefficient of friction. This coating acts as a dry lubricant, significantly reducing the force needed for installation and minimizing drag in dynamic applications.

Superior Chemical Resistance

The coating provides a barrier that protects the more vulnerable elastomer core from aggressive chemicals, acids, and solvents. This makes it suitable for demanding industries like chemical processing and pharmaceuticals.

Elimination of Stiction

The non-stick surface prevents the O-ring from adhering to mating parts, especially after long periods of static compression. This is critical for parts that must move smoothly after being stationary.

Enhanced Environmental Durability

PTFE is highly resistant to UV radiation. This makes coated O-rings an excellent choice for outdoor equipment, marine environments, and other applications with constant sun exposure.

Added Functional Benefits

The coating provides excellent electrical insulation, which is useful in electronic applications. Furthermore, coatings can be colored, providing a simple and effective way to visually identify O-ring material or size.

Understanding the Critical Trade-offs

While effective, a PTFE coating is not a universal solution. Its limitations are just as important to understand as its benefits.

The Coating is a Thin, Sacrificial Layer

The primary weakness is poor wear resistance. In high-speed or abrasive dynamic applications, the thin coating can flake off or wear away, eliminating its benefits and potentially introducing contaminants into the system.

Not a Replacement for Solid PTFE

A solid PTFE O-ring is a rigid, non-compressible component used in specific high-pressure, static applications. A coated O-ring is fundamentally different, as it retains the "squish" of its rubber core and is not intended for the same high-load scenarios.

Potential for Particulate Contamination

If the coating flakes, these small PTFE particles can enter the process stream. This is often unacceptable in sensitive applications like food, beverage, or semiconductor manufacturing.

Making the Right Choice for Your Application

Selecting the correct seal requires matching the component's properties to your primary goal.

- If your primary focus is reducing friction for installation or low-speed movement: A PTFE-coated O-ring is an excellent and cost-effective solution.

- If your primary focus is protecting a seal from moderate chemical exposure: The coating provides a valuable protective barrier for the elastomer core.

- If you are designing a high-wear or high-speed dynamic seal: You must consider the risk of the coating flaking and should explore more durable solutions.

- If your application cannot tolerate any particulate contamination: Be cautious, as a damaged coating can introduce PTFE flakes into the system.

Ultimately, viewing the PTFE coating as a specialized surface treatment rather than a fundamental change to the seal will guide you to the correct application.

Summary Table:

| Component | Material | Primary Function |

|---|---|---|

| Elastomer Core | FKM, EPDM, Silicone | Provides compressibility and primary sealing force |

| PTFE Coating | Polytetrafluoroethylene | Reduces friction, adds chemical resistance, prevents stiction |

Struggling with high friction or chemical degradation in your seals? KINTEK specializes in manufacturing high-performance PTFE components, including custom PTFE-coated O-rings for semiconductor, medical, laboratory, and industrial applications. Our precision production ensures reliable seals that combine the flexibility of elastomers with the superior surface properties of PTFE. Contact us today to discuss your custom sealing solution—from prototypes to high-volume orders.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- Where are PTFE seals commonly used? Critical Sealing Solutions for Extreme Environments

- What properties make PTFE energized seals suitable for cryogenic applications? Reliable Sealing at Ultra-Low Temperatures

- What is the first step in both PTFE production methods? Unlocking the Key to High-Performance Polymer Manufacturing

- What are the benefits of using PTFE valves in the food processing industry? Ensure Safety, Purity, and Efficiency

- What are the key properties of Teflon (PTFE) used in custom parts? | Achieve Peak Performance

- What are the key properties of PTFE rotary shaft seals that make them effective in reducing maintenance?

- What should be considered when using PTFE in specialized applications? Mastering its unique properties for optimal performance

- What role does PTFE play in the construction industry? Solve Critical Movement, Sealing, and Insulation Challenges