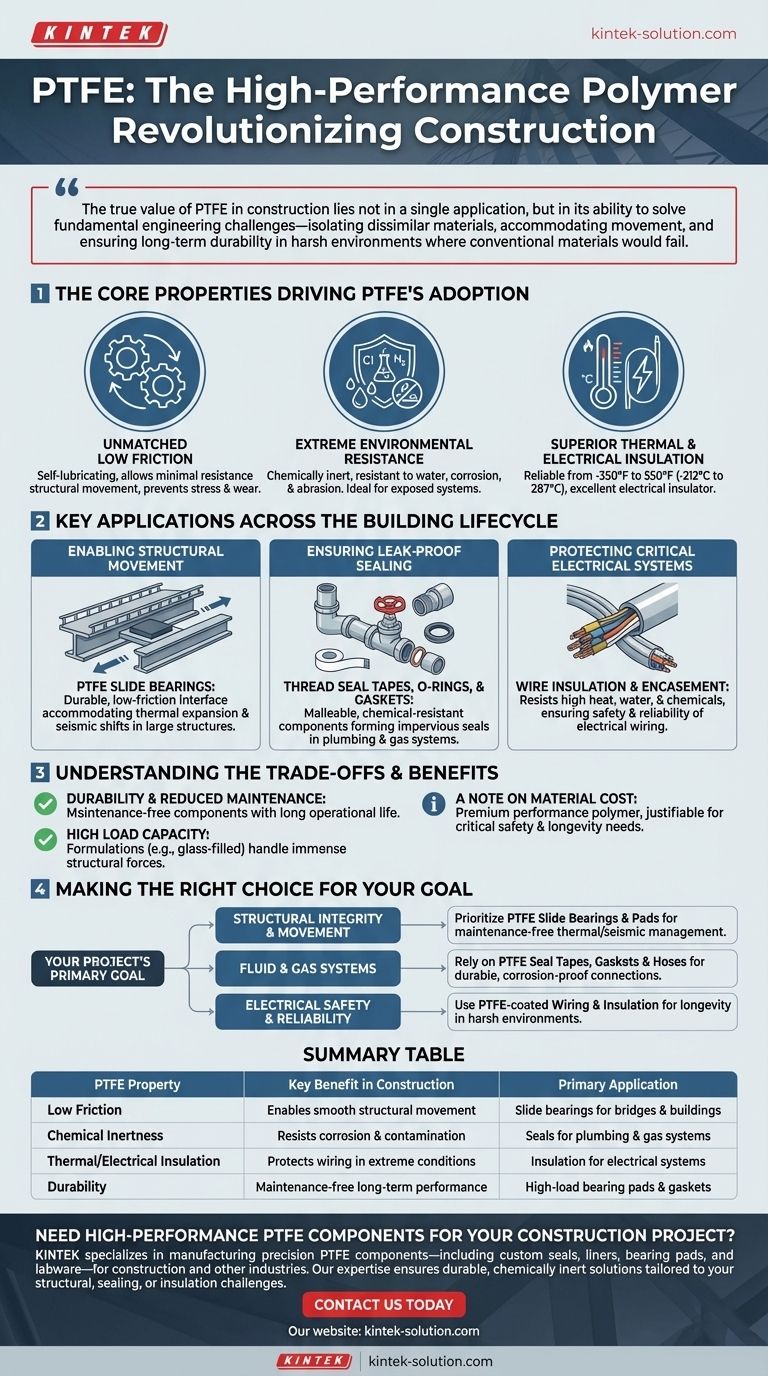

In modern construction, Polytetrafluoroethylene (PTFE) serves as a critical high-performance polymer used to manage structural movement, seal fluid and gas systems, and protect essential electrical wiring. Its value stems from a unique combination of extremely low friction, chemical inertness, and robust resistance to environmental and thermal extremes, making it an indispensable problem-solver in demanding applications.

The true value of PTFE in construction lies not in a single application, but in its ability to solve fundamental engineering challenges—isolating dissimilar materials, accommodating movement, and ensuring long-term durability in harsh environments where conventional materials would fail.

The Core Properties Driving PTFE's Adoption

To understand PTFE's role, we must first look at the core material properties that make it so effective for construction projects. These characteristics directly translate into performance and longevity.

### Unmatched Low Friction

PTFE has one of the lowest coefficients of friction of any solid material. This self-lubricating quality is essential for applications involving movement.

It allows structural elements to slide against each other with minimal resistance, preventing the buildup of stress and wear over time.

### Extreme Environmental Resistance

PTFE is chemically inert, meaning it does not react with most chemicals, and it is highly resistant to water, corrosion, and abrasion.

This makes it ideal for use in plumbing, gas lines, and outdoor components exposed to weather, as it will not degrade or contaminate the systems it's part of.

### Superior Thermal and Electrical Insulation

The material performs reliably across an exceptionally wide temperature range, from -350°F to 550°F (-212°C to 287°C).

Furthermore, PTFE is an excellent electrical insulator, capable of withstanding high voltages. This combination of thermal stability and dielectric strength makes it a top choice for protecting sensitive wiring.

Key Applications Across the Building Lifecycle

These fundamental properties enable PTFE to be used in several distinct and critical areas within the construction industry, from the foundation to the final electrical fit-out.

### Enabling Structural Movement

Large structures like bridges and buildings are not static; they expand and contract with temperature changes and shift during seismic events. PTFE slide bearings are designed specifically to accommodate this movement.

These bearings, often made of glass-filled PTFE cut into pads, are placed between major structural components, such as steel beams and concrete supports.

They provide a durable, low-friction interface that allows for smooth movement, protecting the overall construction from damaging stress without requiring maintenance.

### Ensuring Leak-Proof Sealing

In plumbing and gas systems, preventing leaks is paramount. PTFE's malleability and chemical resistance make it perfect for sealing applications.

It is widely used to create thread seal tapes, O-rings, and envelope gaskets. These components form tight, durable seals around pipes and mating surfaces that are impervious to corrosion and chemical attack.

### Protecting Critical Electrical Systems

The safety and reliability of a building's electrical system depend on proper insulation. PTFE is used to encase and protect electrical wiring.

Its resistance to high heat, water, and chemicals ensures that the wiring remains safe and functional, even in demanding industrial or commercial environments.

Understanding the Trade-offs and Benefits

While PTFE offers significant advantages, it is a specialized material. Understanding its benefits in the context of project requirements is key to using it effectively.

### Durability and Reduced Maintenance

One of the most significant benefits of using PTFE components is their longevity. Slide bearings and seals made from PTFE are effectively maintenance-free.

This long operational life extends the integrity of the entire structure and reduces long-term manufacturing and upkeep costs.

### High Load Capacity

Despite its smooth surface, PTFE can be formulated (e.g., glass-filled) to handle very high loads.

This makes it suitable for bearing pads in large-scale constructions where immense forces are at play between structural elements.

### A Note on Material Cost

PTFE is a premium performance polymer, and its cost is higher than that of more common materials.

Its use is therefore justified in critical applications where its unique properties are necessary to ensure safety, longevity, and performance that commodity materials cannot provide.

Making the Right Choice for Your Goal

Selecting PTFE is a strategic decision based on solving a specific engineering problem. Your project's primary goal will determine the most effective application.

- If your primary focus is structural integrity and movement: Prioritize PTFE slide bearings and pads to manage thermal expansion and seismic loads without maintenance.

- If your primary focus is fluid and gas systems: Rely on PTFE thread seal tapes, gaskets, and hoses for durable, corrosion-proof, and leak-free connections.

- If your primary focus is electrical safety and reliability: Use PTFE-coated wiring and insulation in high-temperature or chemically harsh environments to ensure system longevity.

By understanding these core functions, you can leverage PTFE not just as a material, but as a strategic solution to complex construction challenges.

Summary Table:

| PTFE Property | Key Benefit in Construction | Primary Application |

|---|---|---|

| Low Friction | Enables smooth structural movement | Slide bearings for bridges & buildings |

| Chemical Inertness | Resists corrosion & contamination | Seals for plumbing & gas systems |

| Thermal/Electrical Insulation | Protects wiring in extreme conditions | Insulation for electrical systems |

| Durability | Maintenance-free long-term performance | High-load bearing pads & gaskets |

Need High-Performance PTFE Components for Your Construction Project?

KINTEK specializes in manufacturing precision PTFE components—including custom seals, liners, bearing pads, and labware—for the semiconductor, medical, laboratory, industrial, and construction industries. Whether you require prototypes or high-volume orders, our expertise ensures durable, chemically inert solutions tailored to your structural, sealing, or insulation challenges.

Contact us today to discuss how our PTFE fabrication can enhance your project's safety, longevity, and performance!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What are the recommended applications for Teflon balls? Ideal Uses for Chemical Resistance & Low Friction

- What factors should be considered when choosing between PTFE and rubber washers? Optimize Sealing for Extreme or Everyday Use

- What happens when clearance develops in a PTFE-lined bearing? A Guide to Catastrophic Failure

- How can PTFE be customized for specific applications? Tailor Performance with Fillers & Fabrication

- In what applications are Teflon encapsulated O-rings most suitable? Ideal for Harsh Chemical Seals

- What is the function of check valves in water pump systems? Protect Your Pump and Prevent Backflow

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- How does a PTFE Lined Plug Valve work? A Guide to Superior Corrosion Resistance