The suitability of PTFE energized seals for cryogenic applications stems from a unique combination of material properties. At its core, Polytetrafluoroethylene (PTFE) remains functional and does not become brittle at extreme low temperatures, is chemically inert to virtually all substances, and possesses a very low coefficient of friction, eliminating the need for lubricants that would freeze and fail in such conditions.

While many materials become brittle and fail catastrophically at cryogenic temperatures, PTFE maintains its critical sealing properties. Its unique combination of extreme thermal stability, chemical inertness, and a self-lubricating nature makes it one of the few materials that can reliably prevent leaks of volatile cryogenic fluids.

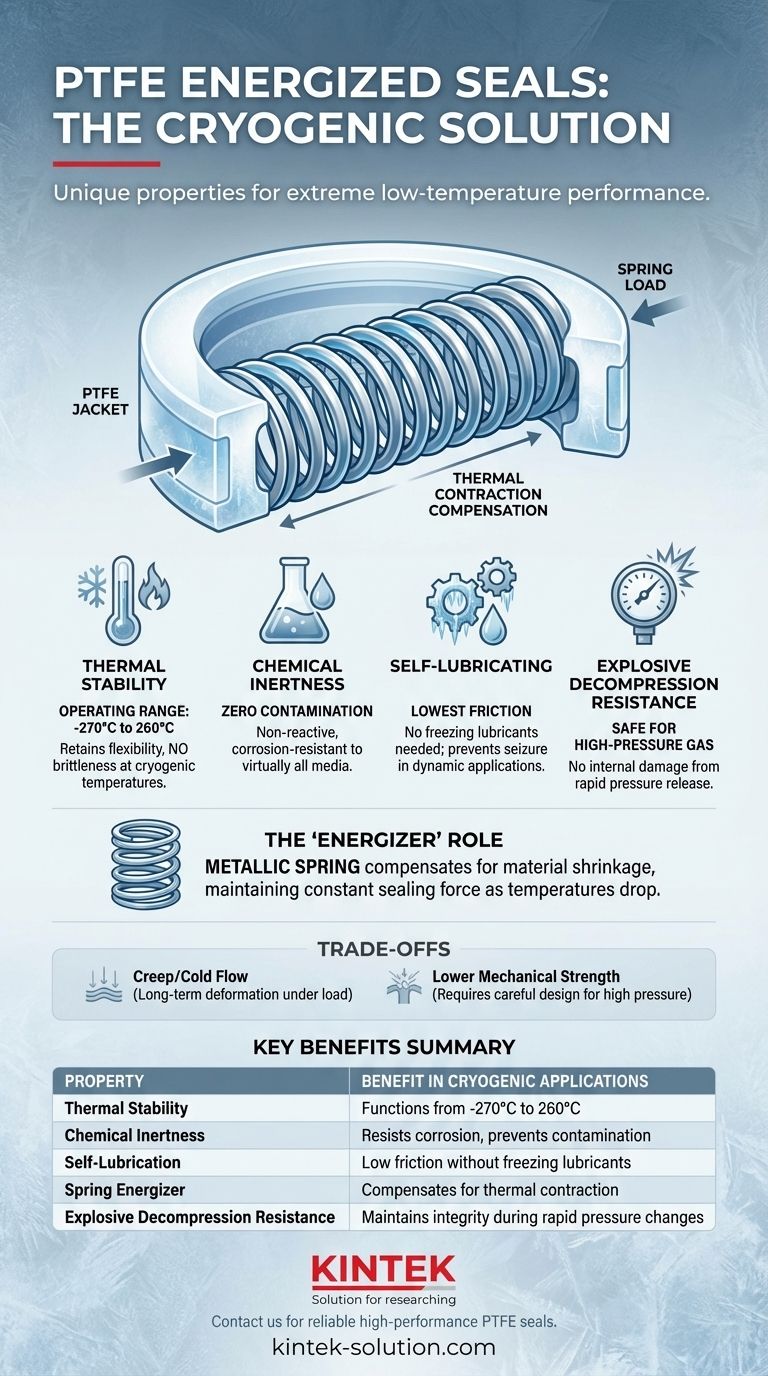

The Core Properties Driving Cryogenic Performance

To fully appreciate why PTFE energized seals are a default choice for systems involving substances like liquid nitrogen (LN2) or liquefied natural gas (LNG), we must examine the specific material characteristics that matter most when temperatures drop below -150°C (-238°F).

Unmatched Thermal Stability

PTFE has an exceptionally wide operating temperature range, often cited as -270°C to 260°C (-454°F to 500°F).

Unlike common elastomers that harden, crack, and lose their sealing ability at cryogenic temperatures, PTFE retains enough flexibility to function effectively as a seal. This thermal resilience is its most fundamental advantage.

Absolute Chemical Inertness

Cryogenic fluids, such as hypergolic propellants used in aeronautics or purified industrial gases, demand zero contamination.

PTFE is chemically non-reactive and corrosion-resistant. It will not degrade or leach contaminants into the media, ensuring the purity and stability of the fluid being transported.

Self-Lubricating Nature

In any dynamic sealing application (e.g., in a valve or loading arm), friction is a primary concern. Traditional grease or oil lubricants would solidify and become useless at cryogenic temperatures.

PTFE has one of the lowest coefficients of friction of any solid material. This self-lubricating or "non-stick" property prevents seizure and allows for smooth actuation of components without external lubrication.

Resistance to Explosive Decompression

In high-pressure gas systems, gas can permeate into a seal's material. If the system pressure is suddenly released, this trapped gas can expand violently, destroying the seal from within.

PTFE is not subject to explosive decompression, a critical safety feature when handling pressurized cryogenic gases that can rapidly change state.

The Role of the "Energizer" in the Seal

A PTFE energized seal is a composite component. It consists of a PTFE jacket and a metallic spring energizer. Understanding the function of the spring is crucial.

What the Energizer Does

The energizer, typically a stainless steel spring, provides a constant, uniform load on the PTFE jacket, pressing its lips against the sealing surfaces.

This mechanical force ensures a tight seal even when there is no system pressure to help activate it.

Why It's Crucial for Cryogenics

All materials contract when cooled. As a system reaches cryogenic temperatures, the PTFE seal jacket and the surrounding hardware will shrink.

The spring energizer compensates for this thermal contraction, maintaining constant pressure on the sealing surfaces and preventing leaks that would otherwise occur due to components shrinking away from each other.

Understanding the Trade-offs

While highly effective, PTFE energized seals are not without limitations. A proper technical evaluation requires acknowledging potential downsides.

Susceptibility to Creep

PTFE can be prone to "creep" or "cold flow," where the material slowly deforms over time under a constant load. This can be a factor in high-pressure static applications.

Lower Mechanical Strength

Compared to metals, PTFE is a relatively soft material. Its resistance to extrusion under very high pressure is limited, which must be accounted for in the hardware design (e.g., by using tight extrusion gaps).

Importance of Design

The performance of a PTFE seal is highly dependent on the proper design of the seal itself and the gland it is installed into. Factors like the spring material, jacket profile, and surface finishes of the hardware are critical for success.

Making the Right Choice for Your Application

Selecting the right seal depends on balancing performance requirements against the specific demands of your cryogenic system.

- If your primary focus is handling highly reactive fluids like propellants: The absolute chemical inertness of PTFE is its most important feature, preventing dangerous reactions and contamination.

- If your primary focus is ensuring a reliable seal during extreme temperature swings: The combination of the PTFE jacket and the metallic spring energizer is the critical feature, as it compensates for thermal contraction.

- If your primary focus is dynamic applications like cryogenic valves or pumps: PTFE's extremely low coefficient of friction is essential for preventing seizure and ensuring smooth operation without lubrication.

Ultimately, understanding these core properties allows you to specify PTFE energized seals with confidence for the most demanding cryogenic environments.

Summary Table:

| Property | Benefit in Cryogenic Applications |

|---|---|

| Thermal Stability | Functions from -270°C to 260°C without brittleness |

| Chemical Inertness | Resists corrosion and prevents fluid contamination |

| Self-Lubrication | Low friction without lubricants that freeze |

| Spring Energizer | Compensates for thermal contraction of components |

| Explosive Decompression Resistance | Maintains integrity during rapid pressure changes |

Need reliable PTFE seals for your cryogenic system? KINTEK specializes in manufacturing high-performance PTFE components—including energized seals, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors. Our precision production and custom fabrication (from prototypes to high-volume orders) ensure your seals perform flawlessly in extreme conditions. Contact us today to discuss your specific requirements!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- Why is PTFE suitable for cryogenic or high-temperature applications? Unmatched Thermal Stability from -450°F to 500°F

- What is PTFE commonly known as and what are its unique properties? Unlock Unmatched Chemical & Thermal Resistance

- What are the base characteristics of PTFE? Unlocking Extreme Performance in Friction, Temperature, and Chemical Resistance

- What are the key benefits of PTFE in custom fabrication? Unlock Performance in Extreme Conditions

- What are the material advantages of machining Teflon? Unlock Unmatched Chemical & Thermal Resistance