At its core, Teflon (PTFE) is defined by four exceptional properties that make it a premier material for custom parts: unparalleled chemical resistance, extreme temperature stability, an incredibly low coefficient of friction, and high-performance electrical insulation. These characteristics allow it to function reliably in environments where most other materials would quickly fail.

The true value of PTFE for custom components is not just one of its properties, but its unique combination of them. This allows for the design of highly specialized parts that remain inert, non-stick, and stable under the most demanding chemical, thermal, and electrical conditions.

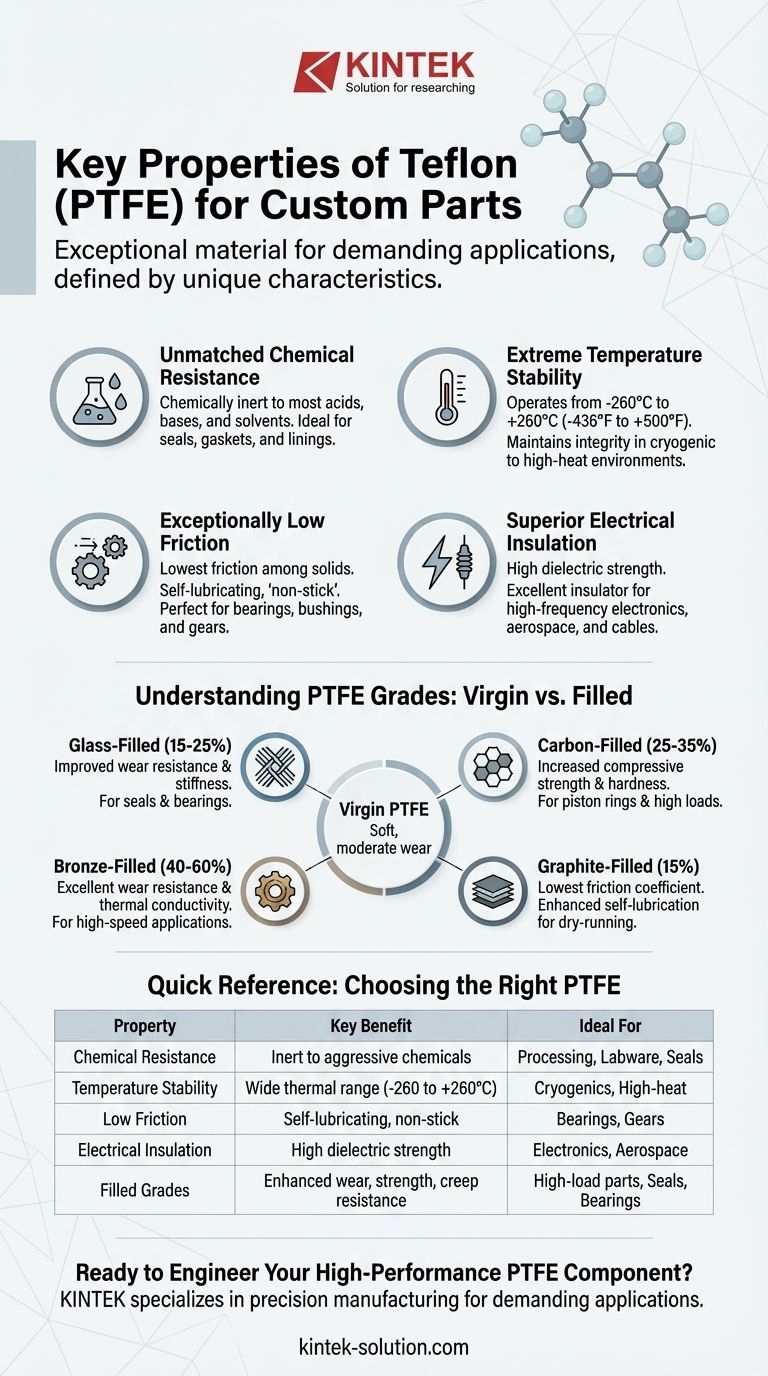

The Core Properties of PTFE Explained

To understand if PTFE is the right choice, you must first appreciate the practical meaning behind its primary characteristics. Each property solves a specific set of engineering challenges.

Unmatched Chemical Resistance

PTFE is almost completely chemically inert. It can withstand aggressive acids, bases, and solvents without degrading.

This makes it the ideal material for seals, gaskets, and linings used in chemical processing, pharmaceuticals, and laboratory equipment.

Extreme Temperature Stability

This material maintains its integrity across an exceptionally wide thermal range, typically from -260°C to +260°C (-436°F to +500°F).

This stability ensures that custom parts will not become brittle in cryogenic applications or deform in high-heat industrial processes.

Exceptionally Low Friction

PTFE has one of the lowest coefficients of friction of any solid material, giving it a distinct "non-stick" or self-lubricating quality.

This is critical for applications like bearings, bushings, and gears where minimizing wear and resistance is paramount.

Superior Electrical Insulation

As an excellent electrical insulator, PTFE has a very high dielectric strength. It resists the flow of electricity, preventing short circuits.

This property makes it indispensable for high-frequency electronics, cable insulation, and insulators in aerospace and telecommunications.

Understanding the Trade-offs and Material Grades

While its core properties are impressive, standard PTFE is not without limitations. Understanding these trade-offs is crucial for selecting the right grade for a custom part.

The Challenge of Wear and Deformation

Virgin (unfilled) PTFE is a relatively soft material. Under sustained pressure, it can be susceptible to "creep" (slow deformation) and has only moderate wear resistance.

For mechanical applications involving high loads or abrasive forces, pure PTFE is often not the optimal choice.

Solution: Virgin vs. Filled Grades

To overcome these mechanical limitations, PTFE is often blended with other materials to create filled PTFE compounds.

These fillers enhance specific properties like strength, wear resistance, or thermal conductivity while retaining the base material's core benefits.

Glass-Filled PTFE

By adding 15-25% glass fiber, the material's wear resistance and stiffness are significantly improved. It is a common choice for seals and bearings.

Carbon-Filled PTFE

Adding 25-35% carbon dramatically increases compressive strength and hardness, making it ideal for piston rings and components that must resist deformation.

Bronze-Filled PTFE

With 40-60% bronze filler, the material gains excellent wear resistance and much higher thermal conductivity, helping to dissipate heat in high-speed applications.

Graphite-Filled PTFE

A 15% graphite filler enhances the material's already low friction coefficient, creating an exceptional self-lubricating compound for bearings and seals in dry-running conditions.

Choosing the Right PTFE for Your Application

Your final material choice depends entirely on the primary demand of your application.

- If your primary focus is chemical purity and inertness: Virgin PTFE is the definitive choice, especially for medical, food-grade, or laboratory use.

- If your primary focus is wear resistance under load: Glass-filled or bronze-filled PTFE will provide a much longer service life than virgin grades.

- If your primary focus is compressive strength and creep resistance: Carbon-filled PTFE offers the best performance for high-load mechanical parts.

- If your primary focus is enhanced self-lubrication: Graphite-filled PTFE provides the lowest friction for demanding, low-wear applications.

By matching the specific grade of PTFE to your operational needs, you can engineer a truly optimized and durable custom component.

Summary Table:

| Property | Key Benefit | Ideal For |

|---|---|---|

| Chemical Resistance | Inert to most acids, bases, and solvents | Chemical processing, labware, seals |

| Temperature Stability | Performs from -260°C to +260°C | Cryogenics, high-heat processes |

| Low Friction | Self-lubricating, non-stick | Bearings, bushings, gears |

| Electrical Insulation | High dielectric strength | Electronics, aerospace, cable insulation |

| Filled Grades (e.g., Glass, Carbon) | Enhanced wear resistance, strength, creep resistance | High-load mechanical parts, seals, bearings |

Ready to Engineer Your High-Performance PTFE Component?

At KINTEK, we specialize in manufacturing precision PTFE components—from seals and liners to custom labware—for the most demanding applications in the semiconductor, medical, laboratory, and industrial sectors. Whether you need the chemical purity of virgin PTFE or the enhanced mechanical properties of a filled grade, our expertise in custom fabrication ensures your part is optimized for durability and performance.

Let's discuss your project requirements and material needs. Contact our team today for a consultation and quote.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Volumetric Flasks for Advanced Scientific and Industrial Use

People Also Ask

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability