At its core, the use of PTFE seals is driven by their exceptional performance in extreme conditions where other materials fail. You will find them in everything from aerospace engines and chemical processing plants to hydraulic systems and medical devices due to their unique combination of chemical inertness, wide temperature range, and low-friction properties.

PTFE seals are not general-purpose components; they are specialized solutions for demanding environments. Their selection indicates a need to solve a specific challenge related to aggressive chemicals, extreme temperatures, or critical low-friction movement.

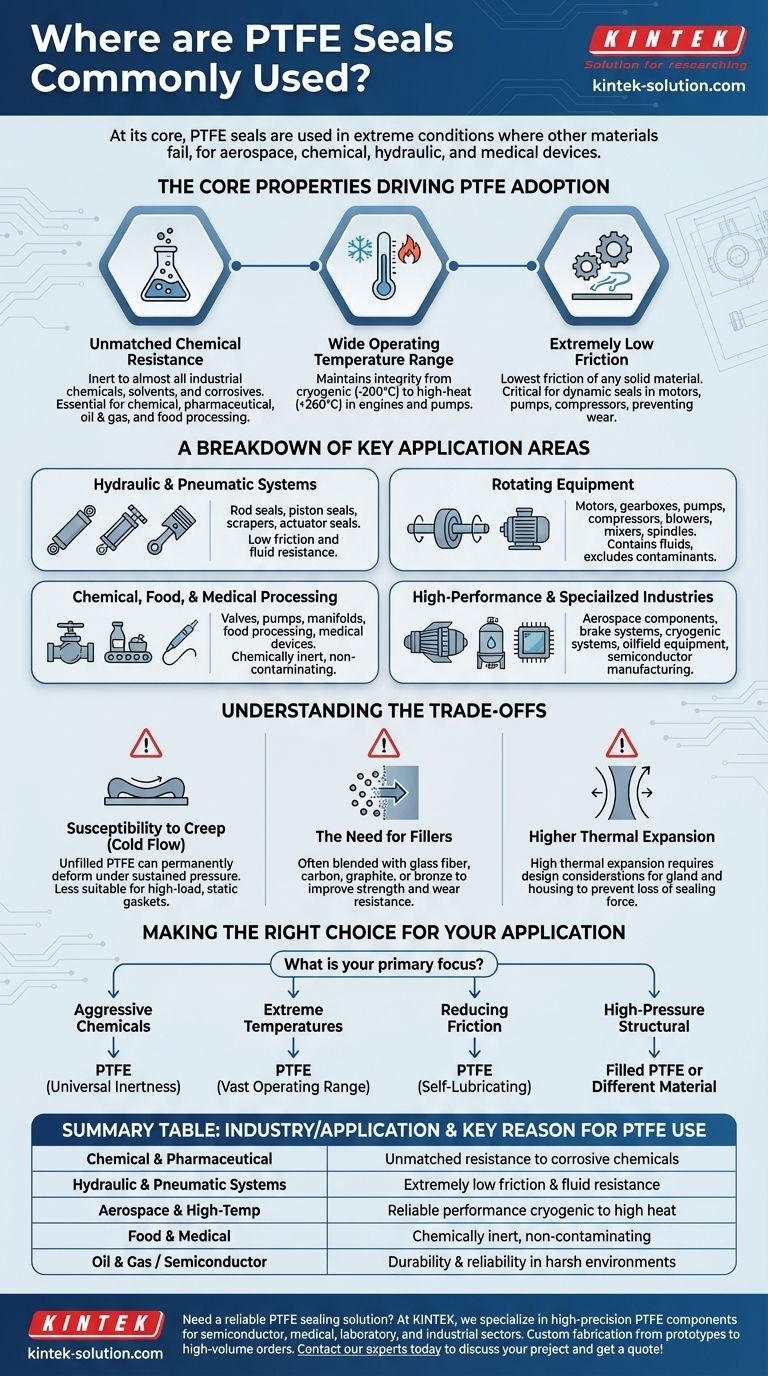

The Core Properties Driving PTFE Adoption

To understand where PTFE seals are used, one must first understand why they are chosen. Their widespread application is a direct result of a few key material characteristics.

Unmatched Chemical Resistance

PTFE is virtually inert to almost all industrial chemicals, solvents, and corrosive agents. This makes it an essential sealing material in chemical and pharmaceutical processing, oil and gas, and food production, particularly when dealing with acidic media.

Wide Operating Temperature Range

PTFE seals maintain their integrity and performance across an exceptionally broad temperature spectrum, from cryogenic applications (-200°C) to high-heat environments found in jet engines or industrial pumps (+260°C).

Extremely Low Friction

PTFE has one of the lowest coefficients of friction of any solid material, often compared to wet ice on wet ice. This "non-stick" or self-lubricating property is critical for dynamic seals in motors, pumps, compressors, and hydraulic actuators, preventing wear and reducing energy consumption.

A Breakdown of Key Application Areas

These core properties allow PTFE seals to be deployed across a diverse range of demanding industries and equipment.

Hydraulic and Pneumatic Systems

This is a classic application for PTFE. You will find them used as rod seals, piston seals, scrapers, and actuator seals in hydraulic and pneumatic cylinders, where low friction and resistance to hydraulic fluid are paramount.

Rotating Equipment

In machinery with rotating shafts, PTFE seals are essential for containing fluids and excluding contaminants. Common uses include motors, gearboxes, pumps, compressors, blowers, mixers, and spindles.

Chemical, Food, and Medical Processing

Due to its chemical inertness and non-contaminating nature, PTFE is a default choice here. Applications include seals and gaskets for valves, pumps, manifolds, and food processing equipment like conveyor belts and dispensing systems. Its use in medical devices like catheters is also common.

High-Performance and Specialized Industries

PTFE's reliability under extreme conditions makes it a staple in specialized fields. It is used extensively in aerospace for engine components and brake systems, as well as in cryogenic systems, oilfield equipment, and semiconductor manufacturing.

Understanding the Trade-offs

While highly capable, PTFE is not a universal solution. An objective assessment requires understanding its limitations.

Susceptibility to Creep (Cold Flow)

Unfilled, or "virgin," PTFE can be prone to deforming permanently under sustained pressure, a phenomenon known as creep or cold flow. This makes it less suitable for high-load, static gasket applications without proper design or reinforcement.

The Need for Fillers

To counteract its relatively low mechanical strength and improve wear resistance, PTFE is often blended with fillers like glass fiber, carbon, graphite, or bronze. These "filled" or "bearing grade" versions offer superior performance for specific applications but alter the material's core properties, such as its chemical resistance or electrical insulation.

Higher Thermal Expansion

Compared to metals, PTFE has a high coefficient of thermal expansion. This must be accounted for in the design of the seal gland and housing, especially in applications with wide temperature swings, to prevent loss of sealing force.

Making the Right Choice for Your Application

Selecting the right seal requires matching the material's strengths to your primary operational challenge.

- If your primary focus is sealing against aggressive chemicals: PTFE is almost certainly the correct choice due to its near-universal chemical inertness.

- If your primary focus is performance at extreme temperatures: PTFE's vast operating range makes it a leading candidate for both cryogenic and high-heat applications.

- If your primary focus is reducing friction in a dynamic system: The self-lubricating nature of a PTFE seal will minimize wear and improve efficiency in pumps, motors, or actuators.

- If your primary focus is a high-pressure structural seal: You should investigate a filled PTFE grade or an entirely different material class to avoid issues with creep and extrusion.

Ultimately, specifying a PTFE seal is a decision to prioritize performance and reliability in environments that push materials to their limits.

Summary Table:

| Industry/Application | Key Reason for PTFE Use |

|---|---|

| Chemical & Pharmaceutical | Unmatched resistance to corrosive chemicals and solvents. |

| Hydraulic & Pneumatic Systems | Extremely low friction for dynamic seals and resistance to fluids. |

| Aerospace & High-Temp | Reliable performance from cryogenic (-200°C) to high heat (+260°C). |

| Food & Medical | Chemically inert, non-contaminating, and compliant with hygiene standards. |

| Oil & Gas / Semiconductor | Durability and reliability in harsh, demanding environments. |

Need a reliable PTFE sealing solution for your demanding application?

At KINTEK, we specialize in manufacturing high-precision PTFE components, including seals, liners, and custom labware. Whether you're in the semiconductor, medical, laboratory, or industrial sector, our expertise ensures your components meet the highest standards for chemical resistance, temperature tolerance, and low friction.

We offer custom fabrication from prototypes to high-volume orders, ensuring a perfect fit and optimal performance for your specific needs.

Contact our experts today to discuss your project and get a quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Customizable PTFE Rods for Advanced Industrial Applications

People Also Ask

- What fabrication services are available for PTFE? Shearing, Stamping, Laser Cutting, Molding & Machining

- What are the unique properties of PTFE? The 3 Pillars Driving Demand for High-Performance Parts

- What finishing techniques are effective for machined Teflon parts? Achieve Functional Performance and Dimensional Stability

- What are the main applications of PTFE type Teflon? Unlock Its Versatility for Your Industry

- What factors should be considered when choosing between Nylon and PTFE? Select the Right Material for Your Application