The primary benefits of using PTFE valves in food processing stem from a unique combination of three core properties: extreme chemical inertness, a very wide operating temperature range, and an exceptionally non-stick surface. This makes Polytetrafluoroethylene (PTFE) uniquely suited for environments that demand the highest levels of hygiene, product purity, and operational reliability.

Choosing PTFE is not merely a material specification; it is a strategic decision to safeguard product integrity and maximize operational efficiency. The material's inherent properties directly address the most critical challenges of food safety, aggressive cleaning cycles, and production uptime.

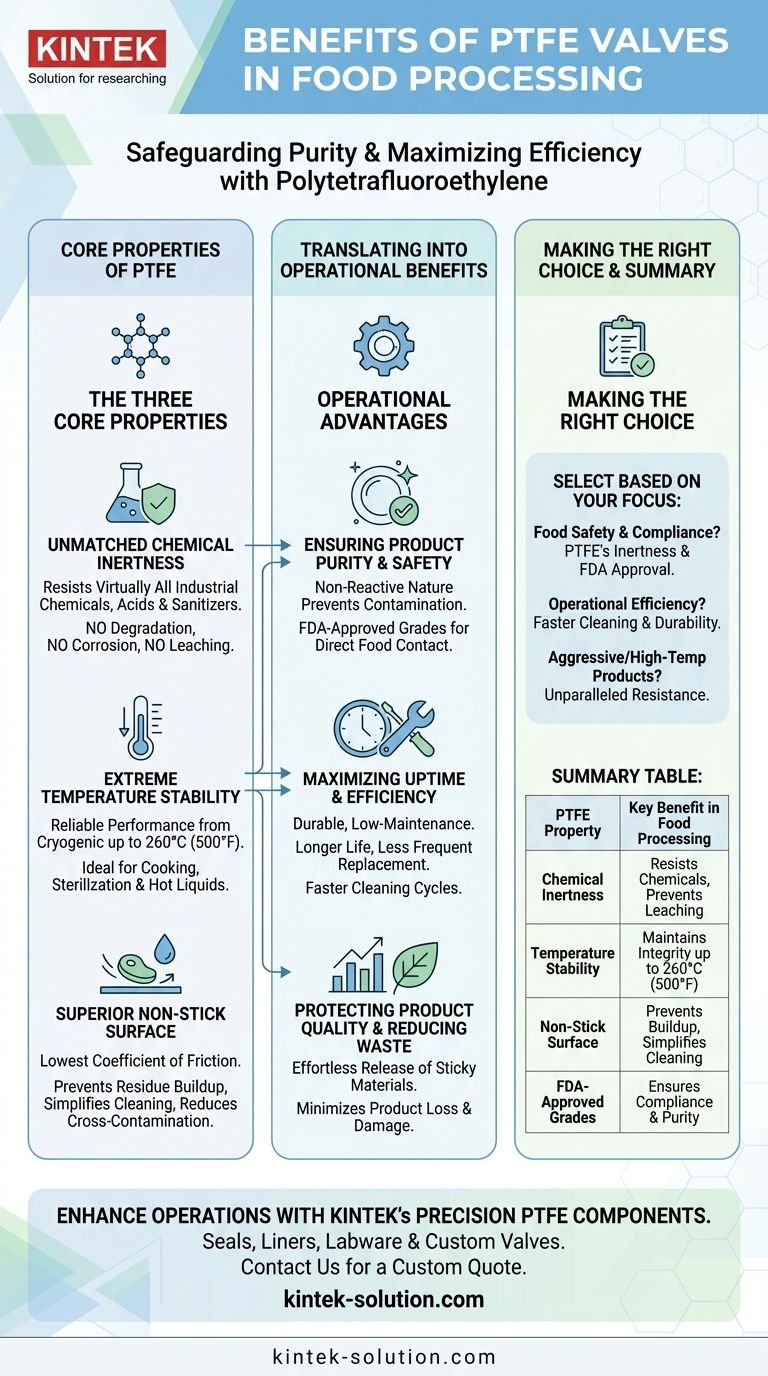

The Three Core Properties of PTFE

The value of PTFE in food processing applications, particularly in critical components like valves, is rooted in its fundamental molecular structure. These inherent characteristics translate directly into tangible operational advantages.

Unmatched Chemical Inertness

PTFE is highly resistant to virtually all industrial chemicals, including the aggressive cleaning agents, sanitizers, acids, and alkaline substances common in food processing.

This inertness ensures the valve material will not degrade or corrode when in contact with acidic food products (like citrus or tomato sauces) or during Clean-in-Place (CIP) procedures. It prevents any leaching of material into the food, guaranteeing product purity.

Extreme Temperature Stability

PTFE valves perform reliably across an exceptionally broad temperature range, with some grades tolerating conditions up to 260°C (500°F).

This makes them ideal for processes involving cooking, sterilization, baking, or handling hot liquids. The material maintains its structural integrity and sealing performance without becoming brittle or degrading, a common failure point for lesser polymers.

Superior Non-Stick Surface

PTFE has one of the lowest coefficients of friction of any solid material, creating a surface that resists adhesion. Food products, residues, and potential contaminants slide off easily.

This non-stick property is critical for preventing residue buildup, which can harbor bacteria and lead to cross-contamination. It also dramatically simplifies and accelerates cleaning cycles, reducing the use of water and cleaning agents.

Translating Properties into Operational Benefits

These material properties are not just technical data points; they deliver significant, measurable benefits in a food processing plant by directly impacting safety, efficiency, and quality.

Ensuring Product Purity and Safety

The primary concern in food processing is preventing contamination. PTFE's non-reactive and non-stick nature ensures that nothing from the valve adheres to or leaches into the product stream.

Many PTFE grades are FDA-approved for food contact, providing a clear path to regulatory compliance. This is essential for components like seals, gaskets, and valve bodies that are in the direct flow path.

Maximizing Uptime and Efficiency

The durability and low-maintenance nature of PTFE valves lead to increased operational efficiency. Their resistance to chemical attack and temperature extremes means they last longer and require less frequent replacement than valves made from other materials.

Furthermore, the easy-to-clean surface reduces downtime between production runs. Faster, more effective cleaning cycles mean more time is spent on value-added production.

Protecting Product Quality and Reducing Waste

In processes involving sticky or viscous materials like confectionery, batters, or sauces, the non-stick surface ensures an effortless and complete release of the product.

This minimizes product loss that would otherwise remain stuck to equipment surfaces, improving yield and overall product quality. For delicate items, it prevents damage that can occur when products adhere to machinery.

Understanding the Trade-offs

While PTFE offers exceptional performance, it is critical to understand its limitations to ensure proper application. Objectivity requires acknowledging where other materials might be more suitable.

Lower Mechanical Strength

Compared to metals, PTFE is a relatively soft material. It can be susceptible to abrasion from hard, particulate-laden media and can exhibit "creep," a slow deformation under sustained pressure, especially at higher temperatures.

Higher Initial Cost

PTFE components often have a higher upfront procurement cost compared to those made from elastomers or some stainless steels. This initial investment must be weighed against the total cost of ownership, which is often lower due to reduced maintenance, longer life, and less downtime.

Thermal Expansion

PTFE has a higher coefficient of thermal expansion than metals. In valve design, this must be carefully managed to ensure that seals remain tight and functional across the entire operating temperature range without binding.

Making the Right Choice for Your Process

Selecting the right valve material depends entirely on the specific demands of your application. PTFE provides a powerful solution for the industry's most common and critical challenges.

- If your primary focus is food safety and compliance: PTFE's inertness and available FDA-approved grades provide the highest assurance against product contamination.

- If your primary focus is operational efficiency: The non-stick surface allows for faster cleaning cycles, while its durability minimizes maintenance downtime.

- If your primary focus is handling aggressive or high-temperature products: PTFE's unparalleled chemical and thermal resistance makes it the default choice for challenging media.

Ultimately, specifying PTFE valves is an investment in the long-term reliability and safety of your food processing operations.

Summary Table:

| PTFE Property | Key Benefit in Food Processing |

|---|---|

| Chemical Inertness | Resists acids, alkalis, and CIP chemicals; prevents leaching and corrosion. |

| Temperature Stability | Maintains integrity from cryogenic to 260°C (500°F); ideal for cooking/sterilization. |

| Non-Stick Surface | Prevents residue buildup, simplifies cleaning, and reduces cross-contamination risk. |

| FDA-Approved Grades | Ensures compliance and guarantees product purity for direct food contact applications. |

Enhance Your Food Processing Operations with KINTEK's Precision PTFE Components

Selecting the right valve material is critical for ensuring food safety, maximizing uptime, and protecting product quality. KINTEK specializes in manufacturing high-performance PTFE components—including seals, liners, labware, and custom valves—specifically for demanding industries like food processing, semiconductor, medical, and laboratory.

We understand the unique challenges of your industry. Our expertise in precision production and custom fabrication—from prototypes to high-volume orders—ensures you receive components that deliver unmatched chemical resistance, thermal stability, and non-stick performance.

Ready to invest in the reliability and safety of your process? Let our team help you specify the perfect PTFE solution.

Contact KINTEK today to discuss your application requirements and receive a custom quote.

Visual Guide

Related Products

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

People Also Ask

- What temperature range can PTFE balls withstand? Unlock Extreme Thermal Stability from -200°C to 260°C

- What are the properties of Teflon balls? Unlock Elite Chemical & Friction Resistance

- What are PTFE balls made of and what are their key properties? Unlock Superior Chemical & Thermal Performance

- What industries commonly use PTFE balls? Essential for Chemical, Pharma, and Food Processing

- What materials are used for PTFE balls? A Guide to Virgin PTFE vs. Filled Composites