When using PTFE in specialized applications, you must primarily consider its high coefficient of thermal expansion, its nearly universal chemical inertness, and its unparalleled low-friction surface. While its properties are extreme, they come with specific design and handling requirements that are critical for success, such as the need for expert consultation on chemical compatibility for the most demanding uses.

The central challenge with PTFE is not questioning its high performance, but rather engineering your application to accommodate its unique physical behaviors—particularly how it expands with heat—and ensuring safety during fabrication.

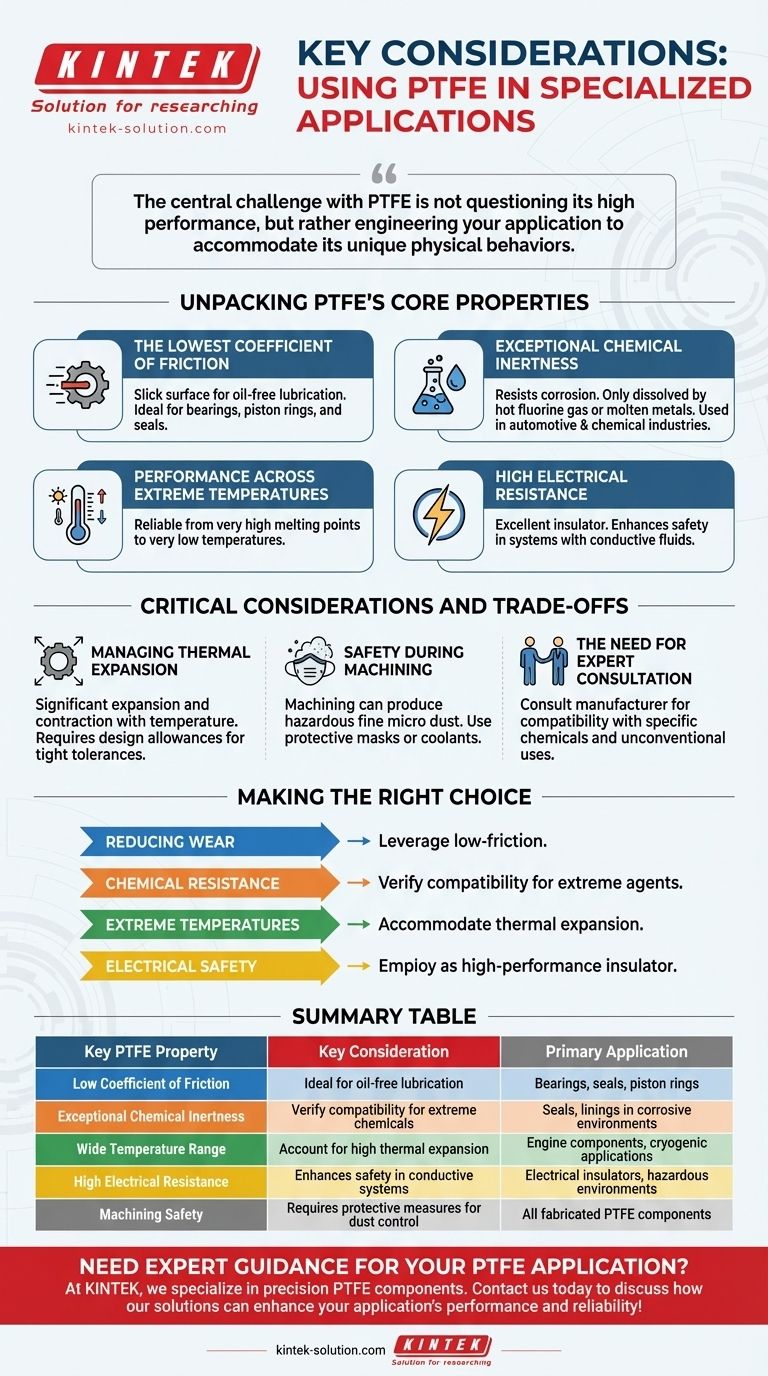

Unpacking PTFE's Core Properties

Polytetrafluoroethylene (PTFE) is a material of extremes. Understanding its distinct characteristics is the first step in leveraging it effectively for any specialized task.

The Lowest Coefficient of Friction

PTFE has a lower coefficient of friction than any other known solid material.

This creates a slick, slippery surface ideal for applications requiring oil-free lubrication. It is a top choice for mechanical parts like bearings, piston rings, and seals where reducing wear and friction is the primary goal.

Exceptional Chemical Inertness

PTFE offers extreme resistance to corrosion and chemical attack.

It is so inert that it can only be dissolved by a few substances, such as hot fluorine gas or certain molten metals. This makes it invaluable in the automotive and chemical industries for parts that are constantly exposed to fuels, lubricants, and other aggressive fluids.

Performance Across Extreme Temperatures

This material functions reliably across an exceptionally wide temperature range.

PTFE has a very high melting point for use in hot environments like engine components, and it also maintains its properties and stability at very low temperatures.

High Electrical Resistance

PTFE is an excellent electrical insulator due to its low electrical conductivity.

This property adds a critical layer of safety in systems involving conductive fluids or potentially explosive atmospheres, preventing short circuits and enhancing overall system integrity.

Critical Considerations and Trade-offs

The same properties that make PTFE uniquely powerful also introduce specific challenges that must be managed during design and fabrication.

Managing Thermal Expansion

The coefficient of thermal expansion is a primary design consideration for PTFE.

This means the material will expand and contract more significantly with temperature changes than many other materials. For components requiring tight tolerances, this dimensional change must be accounted for in the engineering phase to prevent part failure.

Safety During Machining

Fabricating parts from PTFE requires specific safety protocols.

The process of machining PTFE can produce a fine micro dust. This dust is hazardous if inhaled, so it is critical to use a protective mask or perform the work under a coolant.

The Need for Expert Consultation

For truly specialized or novel applications, you cannot rely on general data sheets alone.

It is always recommended to contact the material manufacturer for detailed information on compatibility with specific, aggressive chemicals or for guidance on unconventional uses.

Making the Right Choice for Your Application

To deploy PTFE successfully, align its unique strengths with your primary engineering goal.

- If your primary focus is reducing wear in mechanical systems: Leverage its unparalleled low-friction properties for self-lubricating components like bushings and guide rings.

- If your primary focus is chemical resistance: Use it for seals and linings exposed to corrosive materials, but always verify compatibility for extreme or unusual chemical agents.

- If your primary focus is performance in extreme temperatures: Select PTFE for its stability, but be sure your design accommodates its significant thermal expansion.

- If your primary focus is electrical safety: Employ it as a high-performance insulator, especially in applications with conductive or hazardous fluids.

By understanding both its unmatched capabilities and its practical limitations, you can engineer solutions that capitalize on everything PTFE has to offer.

Summary Table:

| Key PTFE Property | Key Consideration | Primary Application |

|---|---|---|

| Low Coefficient of Friction | Ideal for oil-free lubrication | Bearings, seals, piston rings |

| Exceptional Chemical Inertness | Verify compatibility for extreme chemicals | Seals, linings in corrosive environments |

| Wide Temperature Range | Account for high thermal expansion | Engine components, cryogenic applications |

| High Electrical Resistance | Enhances safety in conductive systems | Electrical insulators, hazardous environments |

| Machining Safety | Requires protective measures for dust control | All fabricated PTFE components |

Need expert guidance for your PTFE application?

At KINTEK, we specialize in manufacturing precision PTFE components (seals, liners, labware, and more) for semiconductor, medical, laboratory, industrial, and other specialized industries. Our team provides expert consultation on chemical compatibility, thermal expansion management, and custom fabrication from prototypes to high-volume orders.

Contact us today to discuss how our PTFE solutions can enhance your application's performance and reliability!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments