The fundamental properties of PTFE that make its rotary shaft seals so effective at reducing maintenance are its extreme chemical resistance, inherent self-lubrication, wide thermal stability, and durability under high pressure and speed. These characteristics allow the seal to survive and perform in demanding operational conditions where traditional elastomer seals would quickly degrade and fail. This resilience directly translates to longer service intervals and significantly less downtime.

The core reason PTFE seals reduce maintenance is their ability to resist the primary causes of seal failure: chemical attack, friction-induced wear, and thermal degradation. By being nearly immune to these factors, they provide a far more durable and reliable sealing solution for challenging applications.

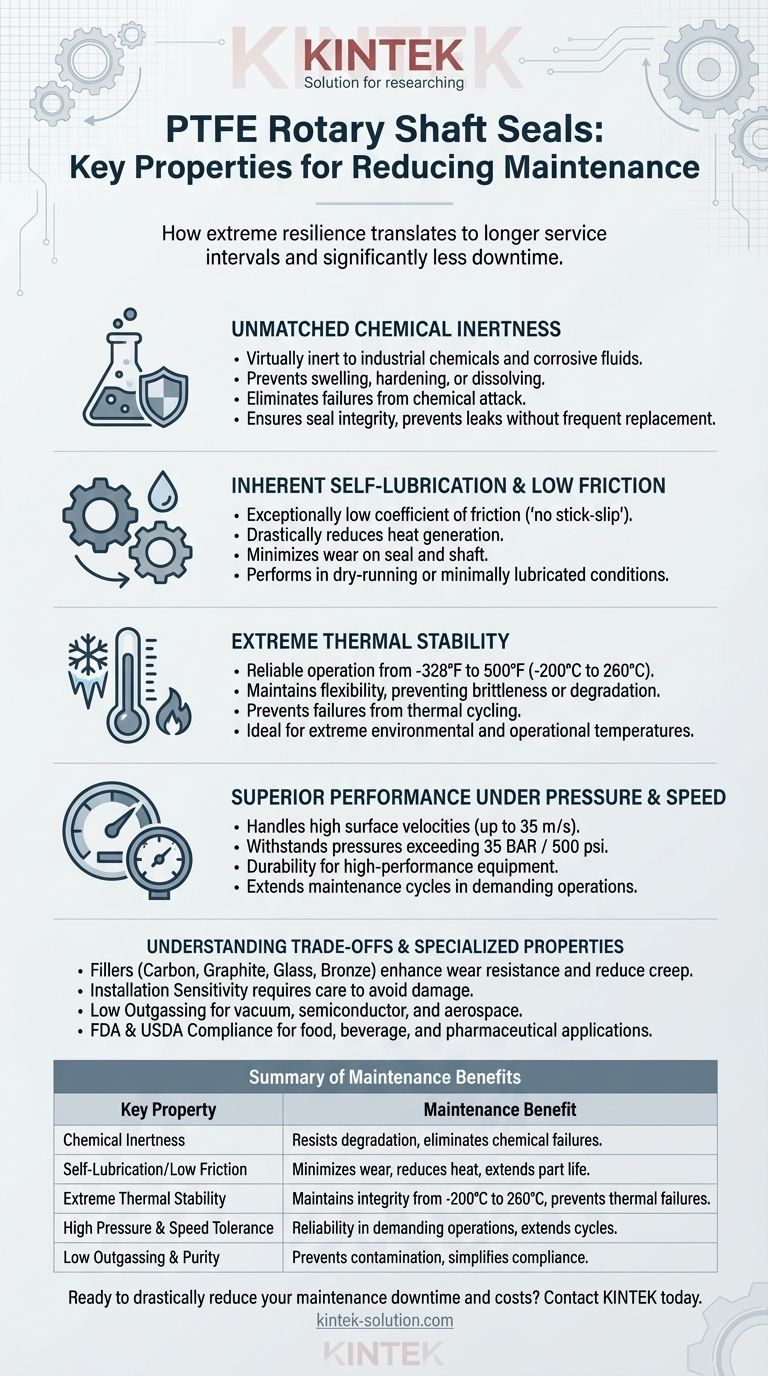

The Core Properties Driving Reliability

To understand why PTFE seals are a superior choice for minimizing maintenance, we must examine the specific advantages each of their core properties provides in a dynamic sealing environment.

Unmatched Chemical Inertness

PTFE is virtually inert to almost all industrial chemicals and corrosive fluids. This is a critical advantage over traditional rubber seals, which can swell, harden, or dissolve when exposed to aggressive media.

This chemical resistance eliminates a common failure mode, ensuring the seal maintains its integrity and prevents leaks without needing frequent replacement due to material incompatibility.

Inherent Self-Lubrication and Low Friction

PTFE has one of the lowest coefficients of friction of any solid material. This self-lubricating nature, often described as "no stick-slip," is crucial in rotary applications.

This property drastically reduces the heat generated between the seal lip and the rotating shaft, which minimizes wear on both components. It also allows the seal to perform in dry-running or minimally lubricated conditions where an elastomer seal would overheat and fail almost instantly.

Extreme Thermal Stability

PTFE seals operate reliably across an exceptionally wide temperature range, typically from -328°F to 500°F (-200°C to 260°C).

Unlike rubber seals that can become brittle at low temperatures or degrade rapidly at high temperatures, PTFE maintains its flexibility and sealing capability. This stability prevents failures caused by thermal cycling and makes it ideal for applications with extreme environmental or operational temperatures.

Superior Performance Under Pressure and Speed

Engineered PTFE seals are designed to handle conditions that far exceed the limits of conventional seals. They can operate at higher surface velocities (up to 35 m/s) and pressures (exceeding 35 BAR / 500 psi).

This durability allows them to be used in high-performance equipment without the risk of premature failure, extending maintenance cycles in demanding and dynamic operations.

Understanding the Trade-offs

While highly effective, PTFE seals are not a universal solution. Understanding their specific characteristics is key to successful implementation and avoiding common pitfalls.

The Role of Fillers

While virgin PTFE has excellent properties, it can be relatively soft. To enhance performance, it is often blended with fillers like carbon, graphite, glass, or bronze.

These fillers improve wear resistance, reduce creep under load, and increase thermal conductivity. Selecting the correct filled compound is critical for optimizing the seal's lifespan for a specific application.

Installation Sensitivity

PTFE is a less forgiving material than elastic rubbers. It has limited elasticity, meaning the seal lip can be damaged if it is not installed with care over sharp corners or threads.

Proper installation tools and procedures are essential to avoid nicking or deforming the seal, which would compromise its performance from the start.

Specialized Properties for Demanding Industries

Beyond the core characteristics, PTFE offers unique properties that make it indispensable in certain high-tech and regulated fields, further reducing maintenance burdens.

Low Outgassing for Vacuum and Aerospace

PTFE emits extremely low levels of gas under vacuum, a property known as low outgassing. This is critical in sensitive environments like vacuum chambers, semiconductor manufacturing, and aerospace applications.

Using PTFE prevents the seal material from contaminating the system, a crucial factor for maintaining process purity and equipment integrity.

Purity and Compliance

Certain grades of PTFE are FDA and USDA compliant, making them suitable for direct contact with food, beverages, and pharmaceutical products.

This compliance eliminates the risk of product contamination and simplifies regulatory adherence, reducing the maintenance overhead associated with meeting stringent hygiene standards.

Making the Right Choice for Your Application

Selecting a PTFE seal is an investment in operational stability. To maximize its maintenance-reducing benefits, align your choice with the primary challenge of your environment.

- If your primary focus is chemical compatibility: PTFE's inertness is the definitive solution for aggressive media, eliminating seal failures from chemical attack.

- If your primary focus is high-speed or dry-running operations: The self-lubricating, low-friction nature of PTFE minimizes wear and heat, dramatically extending the life of both the seal and the shaft.

- If your primary focus is extreme temperature environments: PTFE's wide thermal range ensures seal integrity where elastomers would fail, preventing leaks and costly operational shutdowns.

- If your primary focus is high-purity or vacuum applications: The low outgassing and FDA-compliant properties of PTFE are essential for preventing product or environmental contamination.

Ultimately, choosing a PTFE rotary shaft seal is a strategic decision to enhance equipment reliability and reduce the long-term cost of ownership.

Summary Table:

| Key Property | Maintenance Benefit |

|---|---|

| Chemical Inertness | Resists degradation from aggressive fluids, eliminating failures due to chemical attack. |

| Self-Lubrication / Low Friction | Minimizes wear on seal and shaft, even in dry-running conditions, reducing heat and part replacement. |

| Extreme Thermal Stability | Maintains integrity from -328°F to 500°F (-200°C to 260°C), preventing failures from thermal cycling. |

| High Pressure & Speed Tolerance | Operates at speeds up to 35 m/s and pressures exceeding 35 BAR, ensuring reliability in demanding operations. |

| Low Outgassing & Purity | Prevents contamination in vacuum, semiconductor, food, and pharmaceutical applications, simplifying compliance. |

Ready to drastically reduce your maintenance downtime and costs?

KINTEK specializes in manufacturing high-performance, custom PTFE components—including seals, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors. Our expertise in precision production and custom fabrication, from prototypes to high-volume orders, ensures you get a sealing solution perfectly tailored to withstand your specific operational challenges, whether it's aggressive chemicals, extreme temperatures, or high-speed rotation.

Contact KINTELF today to discuss how our PTFE seals can enhance your equipment's reliability and reduce your total cost of ownership.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- How does PTFE compare to other low-friction plastics like UHMW-PE and Nylon? A Guide to Material Selection

- What is the hardness range of PTFE on the Shore D scale? Leveraging Its Softness for Superior Performance

- What are some important physical property values for PTFE? Master Its Extreme Performance for Demanding Applications

- Why is PTFE considered a significant discovery? A Material That Revolutionized Industry

- What is the working temperature range of PTFE? Master Extreme Heat and Cryogenic Applications