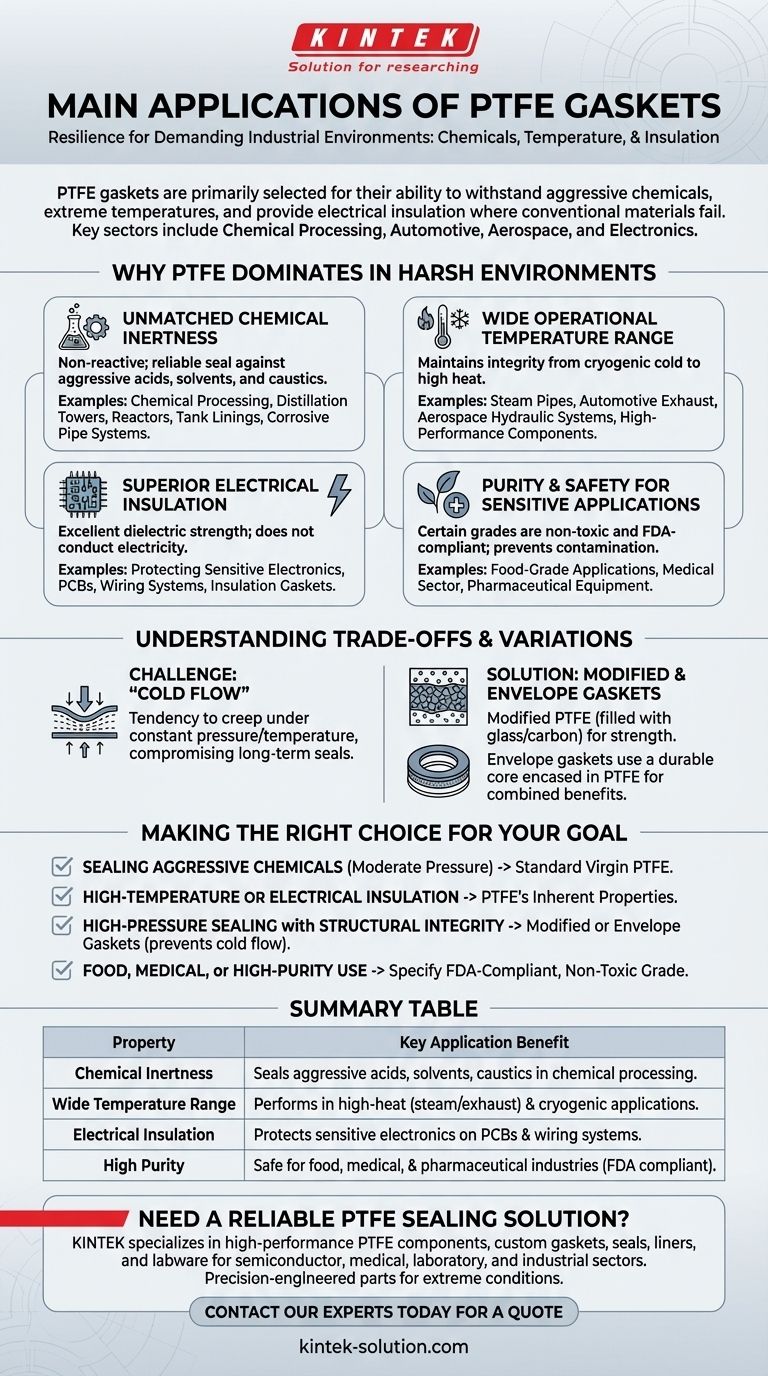

In short, Polytetrafluoroethylene (PTFE) gaskets are primarily used in demanding industrial applications where seals must withstand aggressive chemicals, extreme temperatures, or require electrical insulation. Key sectors include chemical processing, automotive manufacturing, aerospace, and electronics, where they are found in everything from pipe flanges and engine seals to fuel hoses and circuit board insulators.

The core reason for selecting a PTFE gasket is not its versatility, but its resilience. Its applications are defined by environments where conventional sealing materials would quickly fail due to chemical attack, heat degradation, or electrical conductivity.

Why PTFE Dominates in Harsh Environments

The widespread use of PTFE gaskets is a direct result of a unique combination of material properties. Understanding these properties is key to understanding its applications.

Unmatched Chemical Inertness

PTFE is famously non-reactive. It provides a reliable seal in the presence of aggressive media that would corrode or dissolve other materials.

This makes it indispensable for equipment in the chemical processing industry, including distillation towers, heat exchangers, reactors, and tank linings. It is also used for sealing pipes that convey caustic chemicals, acids, solvents, and hydrocarbons.

Wide Operational Temperature Range

PTFE maintains its integrity across a broad spectrum of temperatures, from cold-pressing systems to high-heat applications.

This property allows it to be used in high-pressure steam pipes, automotive exhaust pipes, and aerospace hydraulic systems. It is often chosen as a high-performance replacement for materials like polyethylene in demanding computer and aerospace components.

Superior Electrical Insulation

PTFE is an excellent electrical insulator, meaning it does not conduct electricity. This property is known as high dielectric strength.

This makes it a critical component for protecting sensitive electronics. Common applications include insulation gaskets for wiring systems and protective components on printed circuit boards (PCBs).

Purity and Safety for Sensitive Applications

Certain grades of PTFE are non-toxic and compliant with FDA regulations, ensuring they do not contaminate the media they are in contact with.

This purity is essential for food-grade applications and the medical sector, where contamination control is non-negotiable.

Understanding the Trade-offs and Variations

While standard PTFE is incredibly capable, it is not without limitations. This has led to the development of specialized versions for specific challenges.

The Challenge of "Cold Flow"

Pure, or "virgin," PTFE has a tendency to deform or "creep" over time when subjected to constant pressure and temperature, a phenomenon known as cold flow. This can compromise the long-term integrity of a seal in high-pressure applications.

The Solution: Modified and Envelope Gaskets

To counter this, engineers use modified PTFE, which is filled with materials like glass or carbon to enhance its strength and resistance to creep. These are used in corrosion-resistant pipelines and high-frequency communication equipment where stability is key.

Another solution is the PTFE envelope gasket. This design features a durable core material (like rubber or metal) encased in a thin "envelope" of pure PTFE. This provides the universal chemical resistance of PTFE on all contact surfaces while relying on the core for structural strength and pressure resistance.

Making the Right Choice for Your Goal

Selecting the correct type of PTFE gasket depends entirely on the specific demands of the application.

- If your primary focus is sealing aggressive chemicals at moderate pressure: Standard virgin PTFE is often the most effective and economical choice due to its near-total chemical inertness.

- If your primary focus is high-temperature or electrical insulation: PTFE's inherent thermal stability and dielectric properties make it a top-tier material for these applications.

- If your primary focus is high-pressure sealing with structural integrity: Look to modified PTFE or PTFE envelope gaskets to prevent seal failure from cold flow.

- If your primary focus is food, medical, or high-purity use: Ensure you specify a grade of PTFE that is certified as non-toxic and FDA-compliant.

Ultimately, understanding PTFE's core properties is the key to deploying it effectively in the world's most demanding sealing applications.

Summary Table:

| Property | Key Application Benefit |

|---|---|

| Chemical Inertness | Seals aggressive acids, solvents, and caustics in chemical processing equipment. |

| Wide Temperature Range | Performs in high-heat (steam/exhaust) and cryogenic applications. |

| Electrical Insulation | Protects sensitive electronics on PCBs and in wiring systems. |

| High Purity | Safe for food, medical, and pharmaceutical industries (FDA compliant). |

Need a reliable PTFE sealing solution for your demanding application?

KINTEK specializes in manufacturing high-performance PTFE components, including custom gaskets, seals, liners, and labware. Whether you're in the semiconductor, medical, laboratory, or industrial sector, we deliver precision-engineered parts that withstand extreme conditions. From prototypes to high-volume orders, our custom fabrication ensures a perfect fit and optimal performance.

Contact our experts today to discuss your specific requirements and get a quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Bottles for Diverse Industrial Applications

People Also Ask

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support