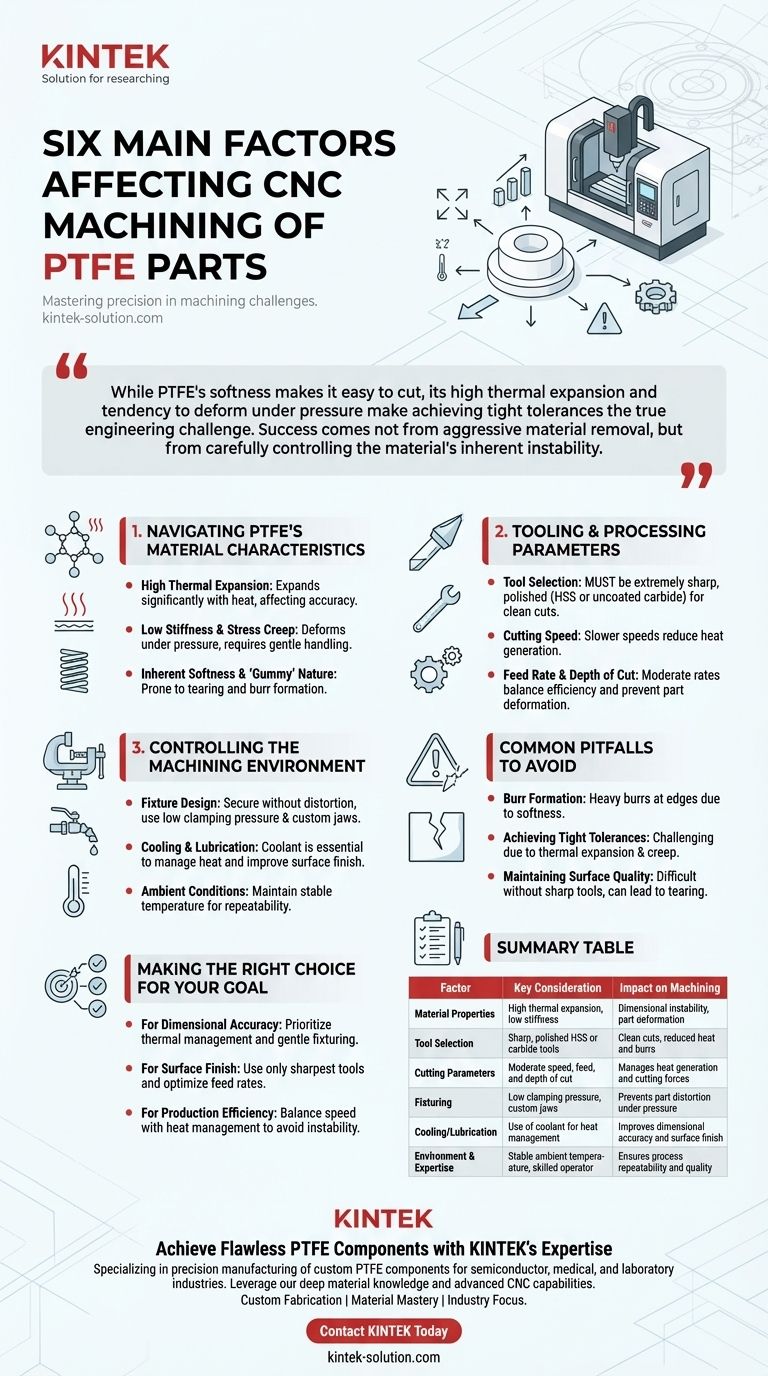

Successfully machining PTFE hinges on mastering six critical factors. These elements are the material's unique characteristics, the selection of cutting tools, the specific processing parameters used, cooling and lubrication strategies, the design of fixtures for workholding, and secondary influences like the machining environment and operator expertise. Understanding how these factors interact is essential for achieving precision with this challenging polymer.

While PTFE's softness makes it easy to cut, its high thermal expansion and tendency to deform under pressure make achieving tight tolerances the true engineering challenge. Success comes not from aggressive material removal, but from carefully controlling the material's inherent instability.

Factor 1: Navigating PTFE's Material Characteristics

The primary challenge in machining PTFE stems directly from its core properties. You must design your process around these traits, not in spite of them.

High Thermal Expansion

PTFE has one of the highest coefficients of thermal expansion among polymers. Even minor heat generated during cutting can cause the material to expand significantly, ruining dimensional accuracy.

This means a part measured at one temperature may be out of tolerance at another. Managing heat is therefore the most critical aspect of the entire process.

Low Stiffness and Stress Creep

PTFE is a soft material that can easily deform or "creep" under pressure. This is especially true when clamping it in a fixture.

Over-tightening a vise will compress the material, and when the part is released, it will spring back to a different dimension than the one that was machined.

Inherent Softness and "Gummy" Nature

The softness that makes PTFE easy to cut also makes it prone to tearing rather than shearing cleanly. This can lead to poor surface finishes and significant burr formation.

Factor 2: Tooling and Processing Parameters

Your choice of tools and the parameters you run them at are your primary defense against the material's natural tendencies.

Tool Selection: Sharpness is Non-Negotiable

Dull tools will rub against the PTFE, generating excess heat and pushing the material rather than cutting it. This exacerbates both thermal expansion and burr formation.

Use extremely sharp and polished cutting tools, preferably made from High-Speed Steel (HSS) or uncoated carbide. A high rake angle and significant relief help create a clean shearing action.

Cutting Speed: Slower Reduces Heat

While it may seem counterintuitive, running lower cutting speeds is often necessary. High speeds generate friction and heat faster than the PTFE can dissipate it, leading to expansion.

The goal is to find a moderate speed that cuts efficiently without causing the material to heat up and become dimensionally unstable.

Feed Rate and Depth of Cut: A Delicate Balance

Use a moderate feed rate to avoid excessive cutting forces that could deform the part. The depth of cut should also be kept relatively small to minimize heat accumulation and improve surface quality.

Factor 3: Controlling the Machining Environment

Workholding and thermal management are just as important as the cutting process itself.

Fixture Design: Secure Without Distortion

Your fixture design must provide rigid support without compressing the PTFE. Use low clamping pressure distributed over a large surface area.

Custom jaws or soft jaws that match the part's contour are highly effective at holding it securely without causing distortion.

Cooling and Lubrication: Managing Heat Directly

While some simple jobs can be done dry, a coolant is highly recommended for any process requiring precision. It serves the primary function of pulling heat away from the part and the tool.

The lubrication aspect also helps ensure a cleaner cut and better chip evacuation, contributing to a superior surface finish.

Ambient Conditions: Consistency is Key

Because of its sensitivity to temperature, maintaining a stable machining environment is crucial for repeatability. Drastic changes in shop temperature can affect the final dimensions of the part.

Common Pitfalls to Avoid

Even with the right strategy, several common challenges can arise when machining PTFE.

Burr Formation

Due to its softness, PTFE tends to form heavy burrs at the edge of a cut. This often requires a secondary manual or automated deburring process, adding time and cost. Extremely sharp tooling is the best way to minimize this.

Achieving Tight Tolerances

The combination of thermal expansion and stress creep makes holding tight tolerances the single greatest difficulty. It requires precise control over heat, gentle fixturing, and often multiple light finishing passes.

Maintaining Surface Quality

Achieving a smooth, clean surface finish can be difficult if the tool rubs or the material tears. In some cases, post-processing techniques like micro-polishing may be necessary to meet specific application requirements.

Making the Right Choice for Your Goal

Your machining strategy should be dictated by the most critical feature of the final part.

- If your primary focus is dimensional accuracy: Prioritize thermal management above all else. Use coolant liberally, moderate your cutting speeds, and employ gentle, precise fixturing.

- If your primary focus is surface finish: Use only the sharpest, most polished cutting tools. Optimize your feed rate and consider adding dedicated finishing passes with a minimal depth of cut.

- If your primary focus is production efficiency: Balance speed with heat. Find the highest cutting speed and feed rate that does not introduce thermal instability or unacceptable burr formation into the part.

By respecting the material's unique properties instead of fighting them, you can transform the challenges of machining PTFE into a predictable and repeatable process.

Summary Table:

| Factor | Key Consideration | Impact on Machining |

|---|---|---|

| Material Properties | High thermal expansion, low stiffness | Dimensional instability, part deformation |

| Tool Selection | Sharp, polished HSS or carbide tools | Clean cuts, reduced heat and burrs |

| Cutting Parameters | Moderate speed, feed, and depth of cut | Manages heat generation and cutting forces |

| Fixturing | Low clamping pressure, custom jaws | Prevents part distortion under pressure |

| Cooling/Lubrication | Use of coolant for heat management | Improves dimensional accuracy and surface finish |

| Environment & Expertise | Stable ambient temperature, skilled operator | Ensures process repeatability and quality |

Achieve Flawless PTFE Components with KINTEK's Expertise

Machining PTFE to meet the demanding standards of the semiconductor, medical, and laboratory industries requires a partner who understands the nuances. KINTEK specializes in the precision manufacturing of custom PTFE components—from complex seals and liners to specialized labware.

We leverage deep material knowledge and advanced CNC capabilities to navigate PTFE's challenges, ensuring your parts deliver on dimensional accuracy, surface finish, and performance.

Let us bring precision and reliability to your next project:

- Custom Fabrication: From initial prototypes to high-volume production runs.

- Material Mastery: Expert handling of PTFE's unique properties for consistent results.

- Industry Focus: Solutions tailored for semiconductor, medical, laboratory, and industrial applications.

Contact KINTEK today to discuss your PTFE machining requirements and receive a expert consultation.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What design considerations are important for custom PTFE parts? Design for Performance & Reliability

- What challenges arise when machining PTFE (Teflon)? Overcome Softness, Heat, and Instability

- What are the main applications of PTFE type Teflon? Unlock Its Versatility for Your Industry

- What chemical processing applications involve PTFE-machined parts? Essential Components for Corrosive & High-Purity Systems

- What are the unique properties of PTFE? The 3 Pillars Driving Demand for High-Performance Parts