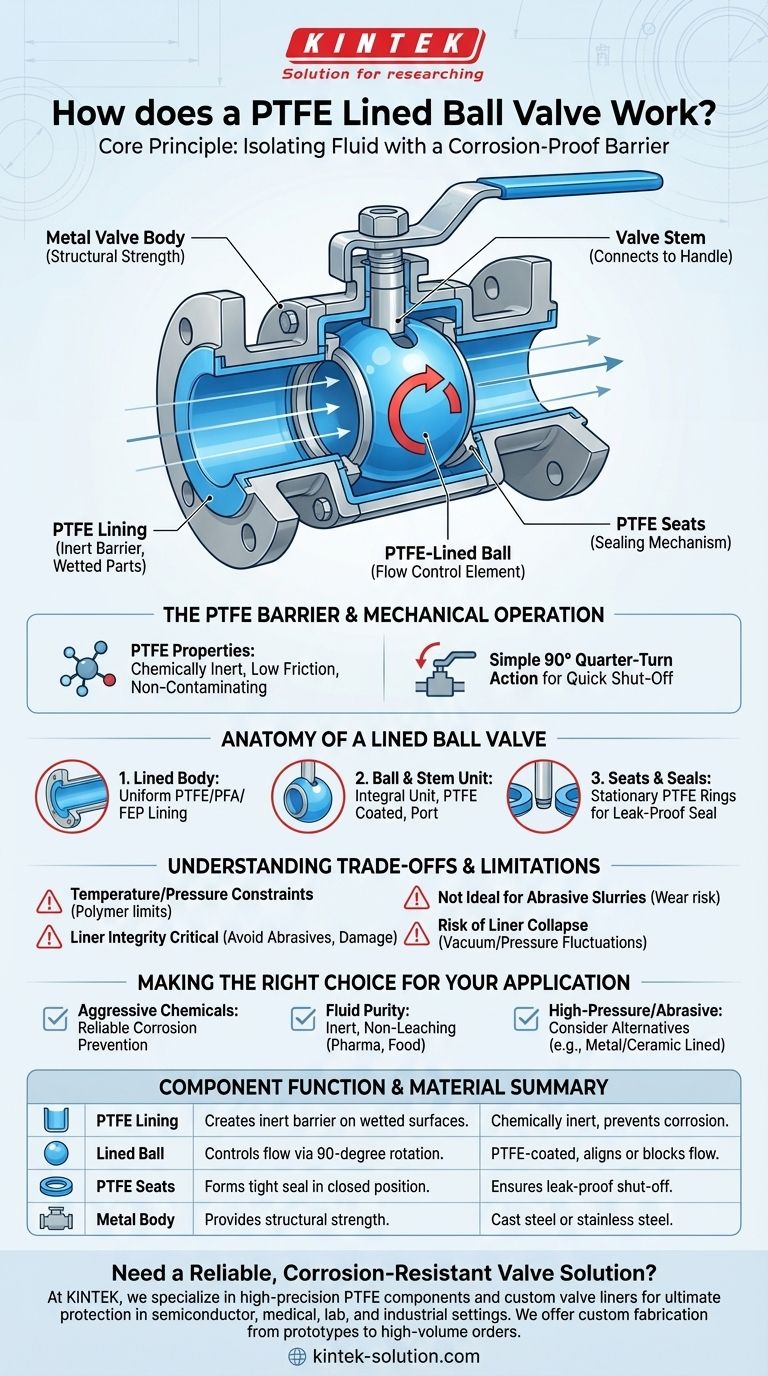

At its core, a PTFE-lined ball valve works by rotating a perforated, PTFE-coated ball 90 degrees within a valve body that is also completely lined with PTFE. When the ball's bore is aligned with the pipe, fluid flows freely. When the handle is turned, the ball rotates to place its solid side against the flow, creating a tight seal with the PTFE seats and stopping the flow completely. The critical function of the PTFE lining is to create an inert, corrosion-proof barrier that isolates all metal valve components from the fluid being controlled.

The essential purpose of a PTFE-lined ball valve is not just to control flow, but to do so while providing complete protection against corrosive or high-purity media. It combines the simple, reliable quarter-turn mechanism of a ball valve with the exceptional chemical resistance of Polytetrafluoroethylene (PTFE).

The Core Principle: Isolating the Fluid

The primary reason to use a PTFE-lined valve is to prevent the fluid from ever touching the structural metal of the valve body. This design solves the problem of corrosion and media contamination.

The PTFE Barrier

PTFE is a fluoropolymer with remarkable properties. It is chemically inert to most substances, has a very low coefficient of friction (making it "slippery"), and is non-contaminating.

This lining is applied to all wetted parts—any surface that comes into contact with the fluid. This creates a seamless, protective shield inside the valve.

Simple Mechanical Operation

The valve's operation is straightforward and rapid, based on a quarter-turn (90-degree) action.

A handle or actuator turns the valve stem, which is connected to the ball. This simple rotation is all that's needed to go from fully open to fully closed, providing quick shut-off capabilities.

The Sealing Mechanism

A tight, leak-proof seal is formed when the lined ball presses against the PTFE valve seats. Because both the ball and the seats are made of or lined with this smooth, conforming material, they create an exceptionally reliable seal when the valve is in the closed position.

Anatomy of a Lined Ball Valve

While simple in operation, the specific construction of these valves is engineered for reliability in harsh environments.

The Lined Body

The outer body is typically made of robust cast steel or stainless steel for structural integrity and pressure containment. The interior, however, features a uniform lining of PTFE, PFA, or FEP that covers every surface the fluid might touch.

The Ball and Stem Unit

The ball is the core flow-control element. It is a sphere with a hole, or port, drilled through the center. The ball itself is lined with PTFE to ensure it has the same chemical resistance as the rest of the valve's interior. Often, the ball and stem are an integral unit to minimize potential leak paths.

Seats and Seals

These are the stationary rings that the ball rotates against. Made of PTFE, they ensure a tight shut-off and maintain the integrity of the corrosion-resistant barrier, even at the most critical sealing points.

Understanding the Trade-offs and Limitations

While highly effective, PTFE-lined valves are not a universal solution. Understanding their limitations is key to using them correctly.

Temperature and Pressure Constraints

PTFE is a polymer, and as such, it has a lower operating temperature and pressure range than a solid metal valve. High temperatures can cause the liner to soften and deform, while extreme pressures can stress it, potentially compromising the seal or the liner's bond to the valve body.

Liner Integrity is Critical

The valve's entire protective function depends on an unbroken liner. Abrasive particles in the fluid, improper installation, or mishandling can scratch or damage the liner. Any breach exposes the base metal to the corrosive media, leading to rapid valve failure.

Not Ideal for Abrasive Slurries

Because PTFE is a relatively soft material, these valves are generally not recommended for services with significant abrasive solids. The constant friction from particles can wear away the lining over time.

Risk of Liner Collapse

In vacuum or significant pressure-fluctuation scenarios, there is a risk of the liner detaching from the valve body, known as liner collapse or blowout. Reputable designs incorporate features to lock the liner into place to mitigate this risk.

Making the Right Choice for Your Application

Selecting the right valve requires matching its strengths to your specific operational goal.

- If your primary focus is handling aggressive chemicals: A PTFE-lined ball valve provides one of the most reliable and cost-effective solutions for preventing corrosion.

- If your primary focus is maintaining fluid purity: The inert, non-leaching nature of the PTFE lining is ideal for pharmaceutical, food, or semiconductor applications.

- If your primary focus is high-pressure or abrasive service: Carefully check the valve's specifications and consider alternatives like metal-seated or ceramic-lined valves that are designed for such conditions.

Ultimately, a PTFE-lined ball valve is an engineered solution that masterfully protects against chemical attack while providing simple, effective flow control.

Summary Table:

| Component | Function & Material | Key Characteristic |

|---|---|---|

| PTFE Lining | Creates an inert barrier on all wetted surfaces. | Chemically inert, prevents corrosion and contamination. |

| Lined Ball | Controls flow via a 90-degree rotation. | PTFE-coated, rotates to align or block the flow path. |

| PTFE Seats | Forms a tight seal against the ball in the closed position. | Ensures a leak-proof shut-off. |

| Metal Body | Provides structural strength and pressure containment. | Typically cast steel or stainless steel. |

Need a reliable, corrosion-resistant valve for your application?

At KINTEK, we specialize in manufacturing high-precision PTFE components, including custom ball valve liners, seals, and labware. Our expertise ensures your equipment provides the ultimate protection against aggressive chemicals in semiconductor, medical, laboratory, and industrial settings.

We prioritize precision production and offer custom fabrication from prototypes to high-volume orders to meet your exact specifications.

Contact KINTEK today to discuss your PTFE-lined valve requirements and get a solution tailored to your needs!

Visual Guide

Related Products

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- What are the overall advantages of using PTFE balls in fluid management systems? Enhance Reliability & Efficiency

- Why are PTFE balls particularly suitable for high-performance applications? Key Properties & Selection Guide

- In which industries are Teflon (PTFE) balls commonly used? Key Applications & Benefits

- How do PTFE balls contribute to reduced maintenance costs? Extend Component Life and Cut Downtime

- How do the chemical properties of PTFE balls influence their performance? Unmatched Durability in Harsh Environments