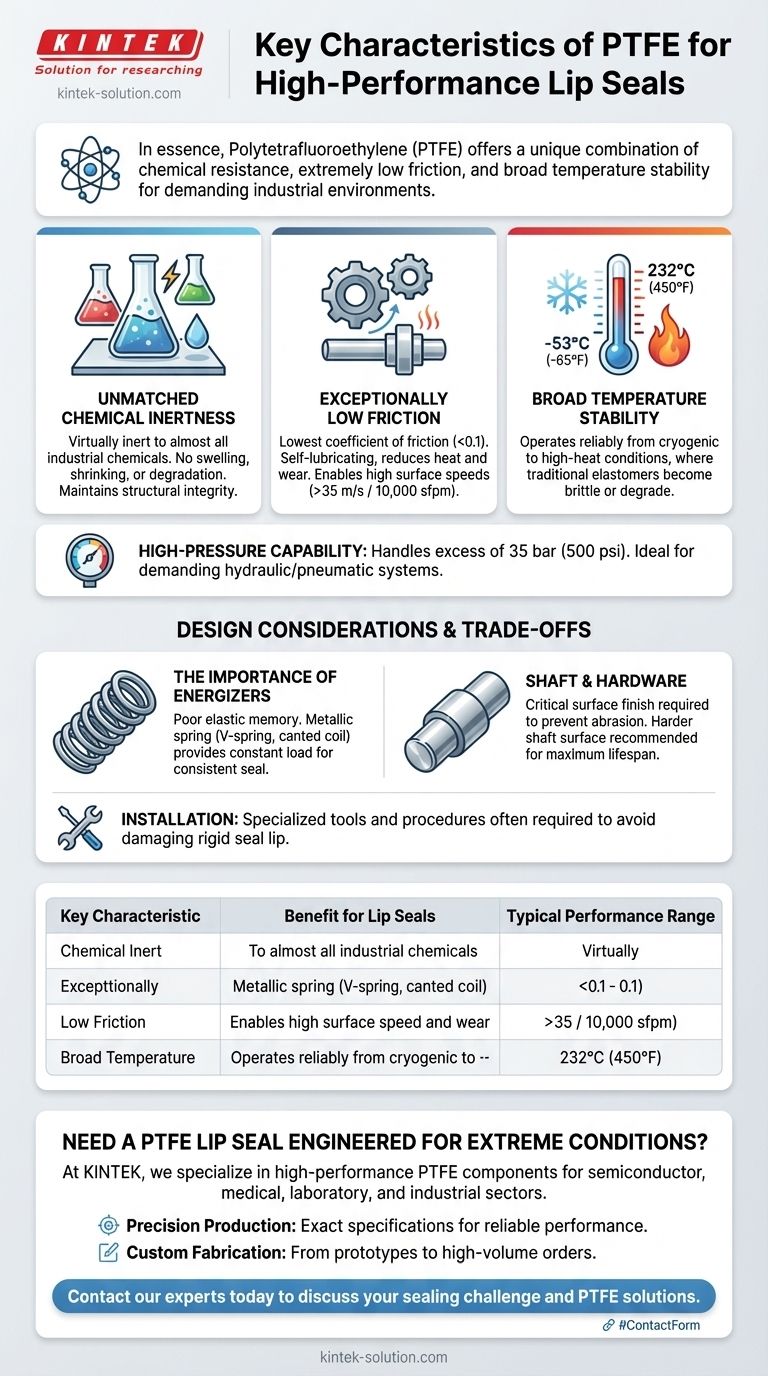

In essence, Polytetrafluoroethylene (PTFE) is uniquely suited for high-performance lip seals due to a powerful combination of three core characteristics: near-universal chemical resistance, an extremely low coefficient of friction, and the ability to operate reliably across a vast temperature range where traditional elastomers would fail. These properties allow PTFE seals to function in the most demanding industrial environments.

The decision to use a PTFE lip seal is not just about material selection; it's about engineering a solution for extreme operating conditions—high speeds, aggressive media, or severe temperatures—that exceed the physical limits of conventional rubber seals.

Why PTFE Excels Where Traditional Seals Fail

PTFE isn't simply a replacement for standard elastomer seals; it's a significant upgrade for applications that involve severe mechanical or chemical stress. Its molecular structure gives it a distinct performance advantage in several key areas.

Unmatched Chemical Inertness

PTFE is virtually inert to almost all industrial chemicals, including aggressive solvents, acids, and bases. This makes it the default choice for sealing systems that handle corrosive media.

Unlike elastomers that can swell, shrink, or degrade upon chemical exposure, PTFE maintains its structural integrity and sealing capability.

Exceptionally Low Friction

PTFE has one of the lowest coefficients of friction of any known solid material. This self-lubricating property is critical for high-speed rotating shafts.

The low friction minimizes heat generation at the contact point, reduces torque requirements, and significantly lessens wear on both the seal and the shaft. This allows for higher surface speeds, often exceeding 35 m/s (10,000 sfpm), without risking premature failure.

Broad Temperature Stability

PTFE seals operate effectively across an exceptionally wide temperature range, typically from -53°C to 232°C (-65°F to 450°F).

This stability allows them to perform reliably in cryogenic applications as well as high-heat environments, conditions that would cause standard rubber seals to become brittle or degrade completely.

High-Pressure Capability

Engineered PTFE lip seals are capable of handling high system pressures, often in excess of 35 bar (500 psi).

This capability, combined with its other properties, makes PTFE ideal for demanding hydraulic and pneumatic applications where pressure, speed, and temperature create a challenging sealing environment.

Understanding the Trade-offs and Design Considerations

While its properties are exceptional, PTFE is not a universal solution. Its unique nature requires specific design considerations to ensure optimal performance and seal longevity.

The Importance of Energizers

Pure PTFE has poor elastic memory compared to rubber. It does not readily spring back to its original shape after being compressed or deflected.

To overcome this, many PTFE lip seals incorporate a metallic spring energizer (like a V-spring or canted coil) that provides a constant, uniform load on the shaft, ensuring a tight and consistent seal even at low pressures.

Shaft and Hardware Requirements

The low-friction benefit of PTFE is best realized when paired with appropriate hardware. The shaft's surface finish is critical for preventing abrasion and ensuring a long service life.

A harder shaft surface is often recommended to maximize the performance and lifespan of the sealing system.

Installation and Handling

PTFE is a relatively rigid material compared to elastomers, which can make installation more challenging. Specialized tools and procedures are sometimes required to avoid damaging the seal lip during assembly.

Making the Right Choice for Your Application

Selecting the correct seal material is driven entirely by the demands of the operating environment. A PTFE lip seal is the superior choice when performance, not cost, is the primary driver.

- If your primary focus is handling aggressive chemicals: PTFE's near-universal inertness ensures seal integrity where almost any elastomer would fail.

- If your primary focus is high-speed rotating shafts: PTFE's ultra-low friction minimizes heat and wear, enabling performance far beyond the limits of rubber seals.

- If your primary focus is extreme temperatures: PTFE provides reliable sealing in both cryogenic and high-heat conditions that would destroy conventional materials.

- If your primary focus is a combination of high pressure, speed, and temperature: PTFE is one of the few materials engineered to withstand all three stressors simultaneously.

Ultimately, choosing a PTFE lip seal is a strategic decision to ensure reliability in applications where seal failure is not an option.

Summary Table:

| Key Characteristic | Benefit for Lip Seals | Typical Performance Range |

|---|---|---|

| Chemical Inertness | Resists aggressive solvents, acids, and bases | Virtually universal chemical resistance |

| Low Coefficient of Friction | Reduces heat and wear; enables high speeds | <0.1; surface speeds >35 m/s |

| Broad Temperature Stability | Performs in extreme heat and cold | -53°C to 232°C (-65°F to 450°F) |

| High-Pressure Capability | Withstands demanding hydraulic/pneumatic systems | >35 bar (500 psi) |

Need a PTFE Lip Seal Engineered for Your Extreme Conditions?

Your application demands a seal that won't fail under pressure, high speeds, or aggressive chemicals. At KINTEK, we specialize in manufacturing high-performance PTFE components—including custom lip seals—for the semiconductor, medical, laboratory, and industrial sectors.

We provide:

- Precision Production: Ensuring every seal meets exact specifications for reliable performance.

- Custom Fabrication: From initial prototypes to high-volume orders, tailored to your unique requirements.

Don't compromise on reliability. Contact our experts today to discuss your sealing challenge and discover how our PTFE solutions can enhance your system's performance and longevity.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Bottles for Diverse Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers