The low coefficient of friction in PTFE bushes is a defining characteristic that provides a powerful combination of benefits for industrial applications. It enables them to act as self-lubricating surfaces, which drastically reduces mechanical wear, minimizes maintenance requirements, and increases the operational lifespan of machinery.

The fundamental benefit of PTFE's low friction is not just reduced wear, but its ability to deliver self-lubricating performance in environments where traditional lubricants are impractical or forbidden. This quality fundamentally changes design possibilities, enabling cleaner, more efficient, and lower-maintenance systems.

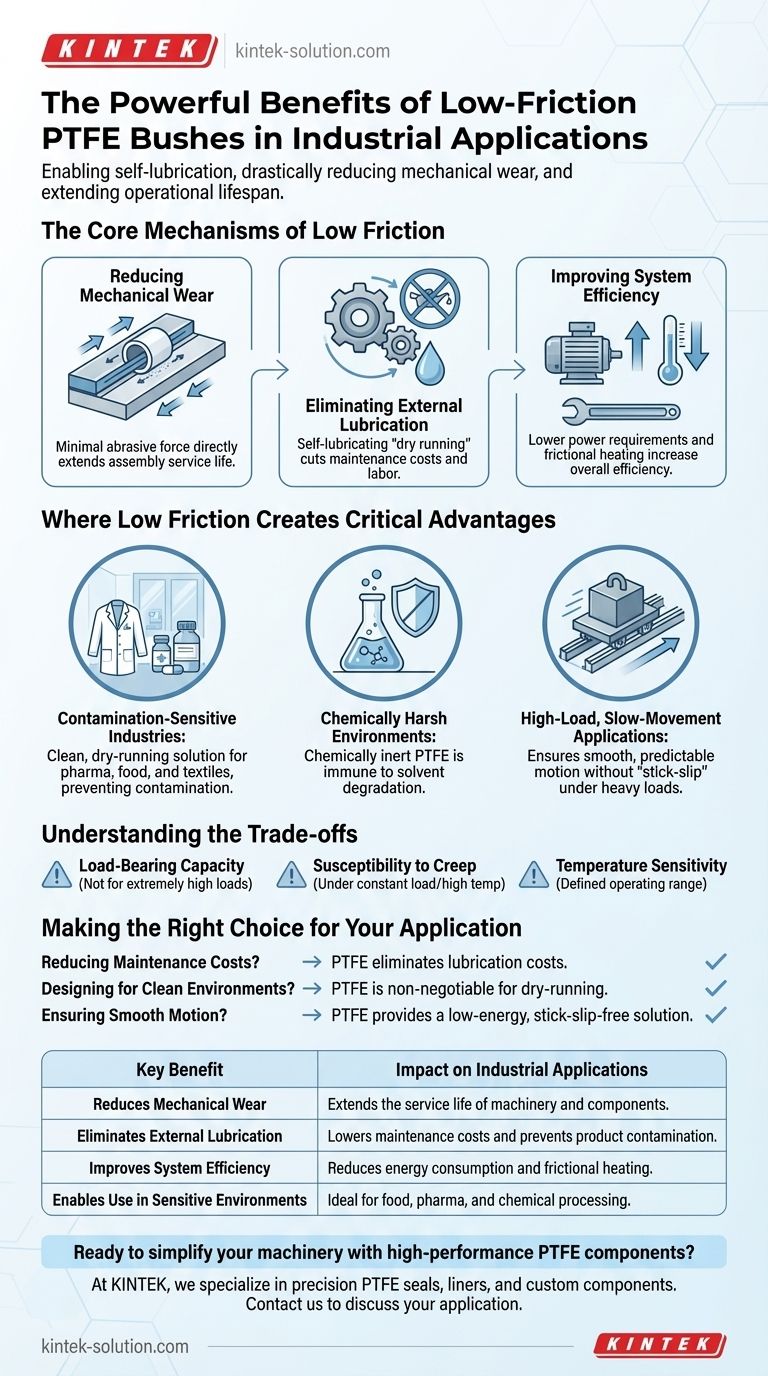

The Core Mechanisms of Low Friction

The uniquely low friction of Polytetrafluoroethylene (PTFE) directly translates into several key operational advantages that are critical in demanding industrial settings.

Reducing Mechanical Wear and Extending Lifespan

When components slide against each other, friction is the primary force that causes material to degrade over time.

PTFE's exceptionally low friction coefficient minimizes this abrasive force, leading to significantly less wear on both the bush and the corresponding moving part. This directly extends the service life of the entire assembly.

Eliminating External Lubrication

Many mechanical systems rely on grease or oil to reduce friction. However, PTFE's inherent properties make it a self-lubricating material.

This capacity for "dry running" eliminates the need for external lubricants entirely. This not only simplifies the design but also cuts down on the costs and labor associated with regular re-lubrication.

Improving System Efficiency

Friction is a form of energy loss, often manifesting as heat. By minimizing this friction, PTFE bushes reduce the energy required to move components.

This leads to lower power and torque requirements, which increases the overall efficiency of the machinery. It also reduces frictional heating, which is crucial for maintaining performance in dynamic applications.

Where Low Friction Creates Critical Advantages

The self-lubricating nature of PTFE is not just a convenience; it is an enabling feature for applications where traditional lubrication is a significant liability.

Contamination-Sensitive Industries

In sectors like pharmaceuticals, food processing, textiles, and papermaking, even a small amount of lubricant can contaminate the final product.

PTFE bushes provide a clean, dry-running solution, ensuring product purity without sacrificing mechanical performance.

Chemically Harsh Environments

PTFE is chemically inert, but the lubricants used in traditional bearings are often not.

In environments with solvents or other aggressive chemicals, lubricants can dissolve or degrade, leading to system failure. PTFE's self-lubricating nature makes it immune to this problem.

High-Load, Slow-Movement Applications

Under heavy loads, lubricated metal surfaces can exhibit "stick-slip" behavior—a stuttering motion as friction is overcome.

PTFE's consistently low friction ensures smooth, predictable movement, which is essential for components like the large sliding blocks used in bridges, tunnels, and pipelines.

Understanding the Trade-offs

While its low friction is a significant asset, PTFE is not a universal solution. An objective evaluation requires acknowledging its limitations.

Load-Bearing Capacity

PTFE is a polymer, not a metal. While strong, it does not possess the same compressive strength or load-bearing capacity as hardened steel or bronze bearings. For extremely high-load applications, its suitability must be carefully evaluated.

Susceptibility to Creep

Under a constant load, especially at elevated temperatures, PTFE can slowly deform over time. This phenomenon, known as creep, must be factored into long-term design considerations to ensure dimensional stability.

Temperature Sensitivity

Like all polymers, PTFE has a defined operating temperature range. Exceeding its thermal limits can compromise its structural integrity and friction characteristics, making it unsuitable for very high-temperature applications where only metals or ceramics can perform.

Making the Right Choice for Your Application

Selecting the right material requires aligning its properties with your primary engineering goal.

- If your primary focus is reducing maintenance and operating costs: PTFE is an ideal choice as it eliminates the material and labor costs associated with lubrication.

- If your primary focus is designing for clean or sterile environments: PTFE's dry-running capability is non-negotiable, as it prevents product contamination from oils and greases.

- If your primary focus is ensuring smooth, efficient motion: PTFE provides a low-energy, stick-slip-free solution that improves overall system performance and reliability.

Ultimately, leveraging PTFE's low friction is about creating simpler, more reliable, and cleaner mechanical systems.

Summary Table:

| Key Benefit | Impact on Industrial Applications |

|---|---|

| Reduces Mechanical Wear | Extends the service life of machinery and components. |

| Eliminates External Lubrication | Lowers maintenance costs and prevents product contamination. |

| Improves System Efficiency | Reduces energy consumption and frictional heating. |

| Enables Use in Sensitive Environments | Ideal for food, pharma, and chemical processing where lubricants are forbidden. |

Ready to simplify your machinery with high-performance PTFE components?

At KINTEK, we specialize in manufacturing precision PTFE seals, liners, labware, and custom components for the semiconductor, medical, laboratory, and industrial sectors. Our expertise ensures you get the right self-lubricating solution to reduce wear, eliminate contamination, and lower maintenance costs—from prototype to high-volume production.

Contact KINTEK today to discuss how our PTFE components can benefit your specific application.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments