The primary benefits of using PTFE in CNC machining stem from its unique combination of material properties: exceptionally low friction, high chemical and temperature resistance, and excellent electrical insulation. These characteristics make it a superior choice for creating highly specific, performance-critical components that other plastics or metals cannot fulfill.

While PTFE's intrinsic properties make it ideal for demanding applications, its successful use in CNC machining is not automatic. The true benefit is realized only when the machining process is adapted to manage its softness and thermal expansion, turning potential challenges into strengths.

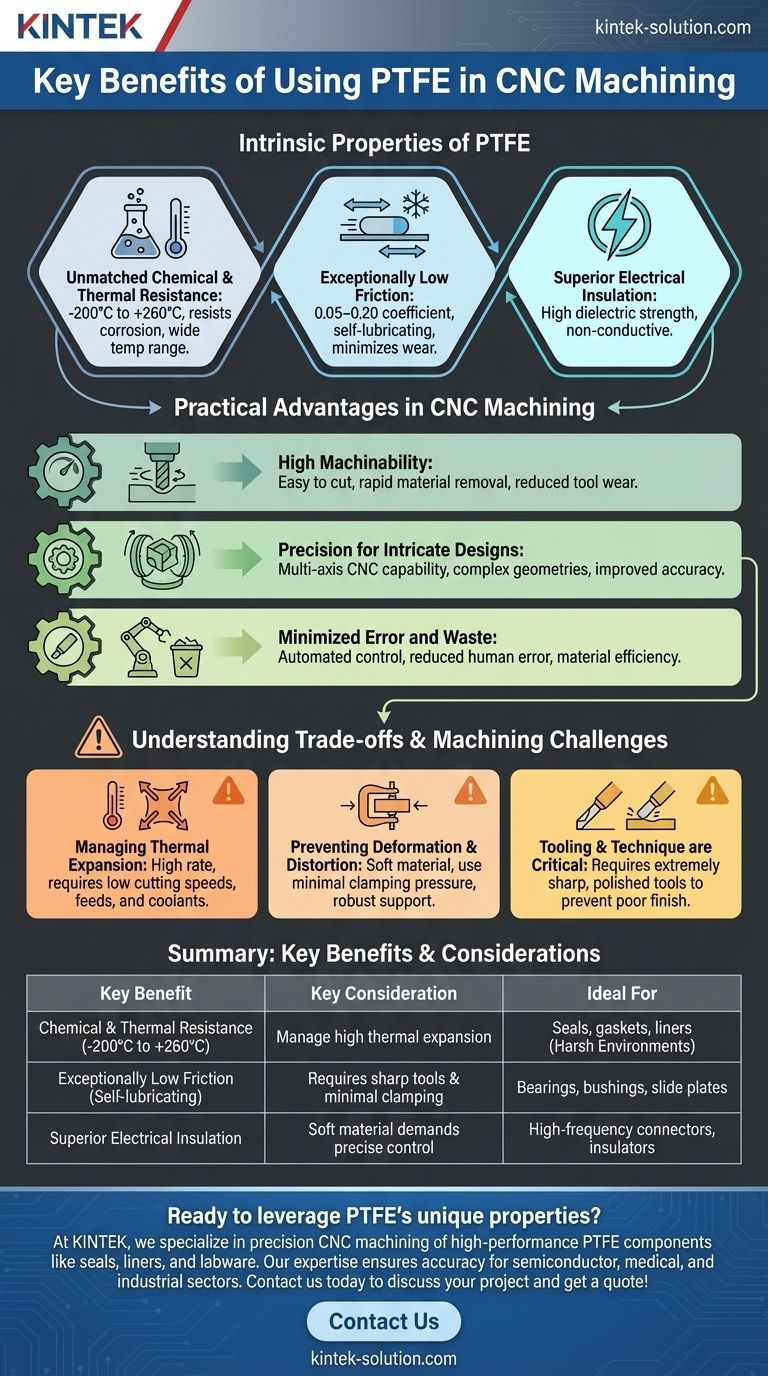

The Intrinsic Properties of PTFE

The value of PTFE begins with its fundamental material characteristics. These properties are why engineers select it for components that must perform under extreme conditions.

Unmatched Chemical and Thermal Resistance

PTFE is almost completely chemically inert, meaning it resists corrosion and degradation from nearly all industrial chemicals and solvents.

Furthermore, it maintains its integrity across an exceptionally wide temperature range, typically from -200°C to +260°C (-328°F to 500°F). This makes it indispensable for parts used in harsh chemical processing, aerospace, and automotive environments.

Exceptionally Low Friction

With a coefficient of friction rivaling wet ice on wet ice (0.05–0.20), PTFE is one of the most slippery solid materials known.

This "self-lubricating" property is a significant advantage for applications like seals, gaskets, bushings, and bearings, where minimizing wear and resistance is critical.

Superior Electrical Insulation

PTFE is an outstanding electrical insulator with high dielectric strength. It does not conduct electricity, making it a first-choice material for insulators, connectors, and components in high-frequency electronic equipment.

Practical Advantages in CNC Machining

When combined with modern CNC technology, PTFE's properties translate into tangible manufacturing benefits, allowing for the creation of precise and complex parts.

High Machinability

PTFE is a soft material that is very easy to cut. This allows for rapid material removal and reduced tool wear, which can increase machining efficiency and lower production costs.

Precision for Intricate Designs

Multi-axis CNC machines can leverage PTFE's softness to create advanced tool paths and produce highly complex geometries. This capability reduces the need for multiple setups, which in turn improves the accuracy and consistency of the final part.

Minimized Error and Waste

The automated and highly controlled nature of CNC machining reduces the rate of human error compared to manual methods. This ensures that the unique properties of PTFE are consistently expressed in every part produced, minimizing material waste.

Understanding the Trade-offs and Machining Challenges

To truly benefit from PTFE, one must understand and mitigate the challenges posed by its unique physical nature. Its advantages are directly linked to its machining requirements.

Managing Thermal Expansion

PTFE has a high rate of thermal expansion. Heat generated during cutting can cause the material to expand, compromising tight tolerances.

To counteract this, machinists must use low cutting speeds and feeds and often employ coolants to prevent heat buildup and maintain dimensional stability.

Preventing Deformation and Distortion

PTFE is soft and can easily be deformed. Excessive clamping pressure in the CNC machine will crush or distort the workpiece, leading to inaccuracies.

Machinists must use minimal clamping pressure and provide robust material support to ensure the part remains stable and true throughout the cutting process.

Tooling and Technique are Critical

The softness of PTFE means that dull tools will not cut it cleanly. Instead, they will push and deform the material, resulting in poor surface finish and "tool chatter."

Using extremely sharp tools, often made of carbide with polished surfaces, is non-negotiable for achieving a clean cut and maintaining the integrity of the part.

Making the Right Choice for Your Application

Choosing PTFE is a strategic decision based on performance requirements. The key is to match its benefits to your specific goal while ensuring your manufacturing partner is an expert in handling its unique challenges.

- If your primary focus is performance in harsh environments: PTFE's chemical inertness and extreme temperature stability make it the ideal choice for seals, gaskets, and linings.

- If your primary focus is low-friction mechanical parts: Its self-lubricating properties are perfect for creating wear-resistant bearings, slide plates, and non-stick surfaces.

- If your primary focus is high-performance electrical components: PTFE's superior dielectric strength makes it the definitive material for high-frequency insulators and connectors.

Ultimately, leveraging PTFE successfully depends on a deep understanding of both the material and the specialized machining process it requires.

Summary Table:

| Key Benefit | Key Consideration | Ideal For |

|---|---|---|

| Chemical & Thermal Resistance (-200°C to +260°C) | Manage high thermal expansion during machining | Seals, gaskets, liners in harsh environments |

| Exceptionally Low Friction (Self-lubricating) | Requires sharp tools and minimal clamping pressure | Bearings, bushings, slide plates |

| Superior Electrical Insulation | Soft material demands precise CNC control | High-frequency connectors and insulators |

Ready to leverage PTFE's unique properties for your critical components?

At KINTEK, we specialize in the precision CNC machining of high-performance PTFE components like seals, liners, and labware. Our expertise in managing PTFE's softness and thermal expansion ensures your parts for the semiconductor, medical, laboratory, and industrial sectors meet the highest standards of accuracy and performance, from prototypes to high-volume production.

Contact us today to discuss your project and get a quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments