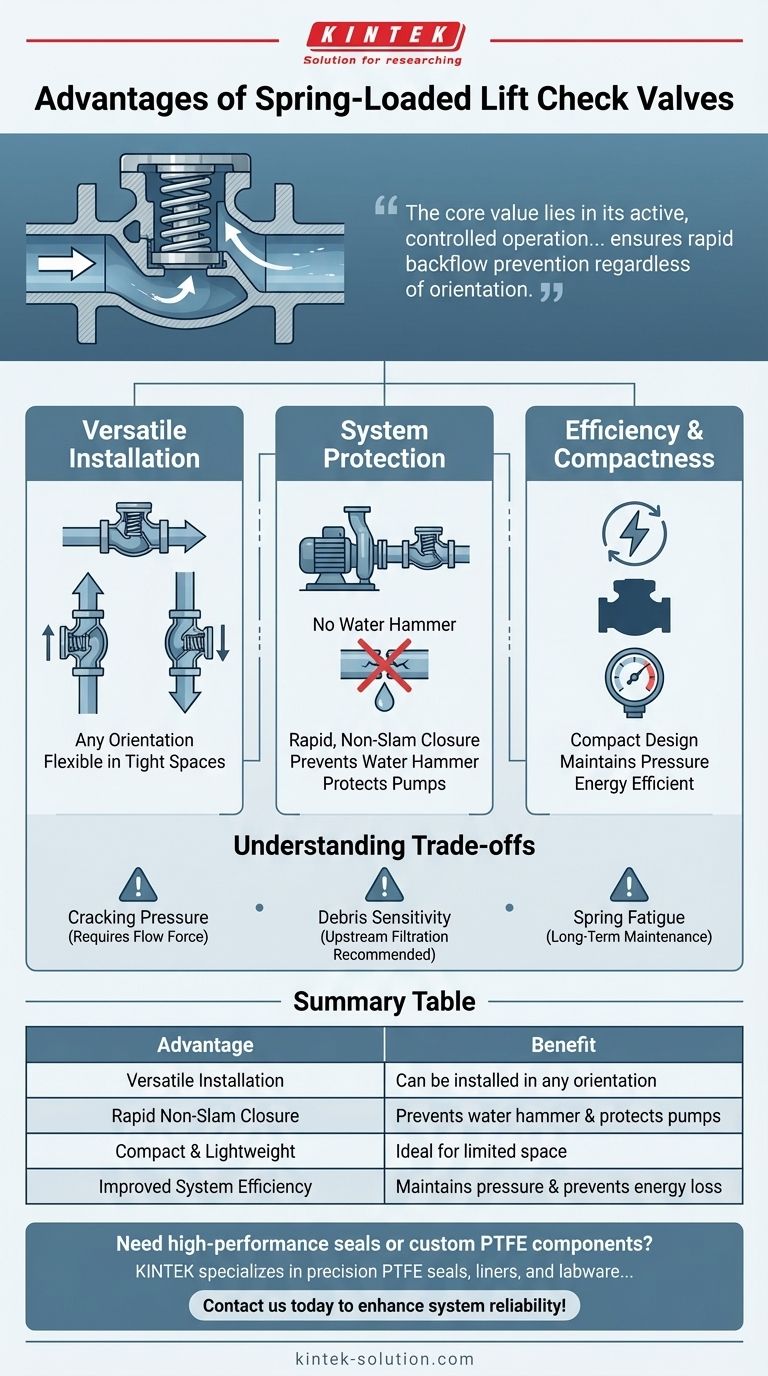

The primary advantages of spring-loaded lift check valves are their ability to be installed in any orientation, their rapid, non-slam closure which prevents water hammer, and their compact design. These features protect pumps from backflow, improve overall system efficiency, and allow for flexible installation in tight spaces.

The core value of a spring-loaded lift check valve lies in its active, controlled operation. Unlike passive, gravity-dependent valves, the spring provides a reliable closing force that ensures rapid backflow prevention regardless of the valve's orientation.

How Spring-Loaded Valves Solve Flow Control Problems

At its heart, a check valve serves one purpose: to allow fluid to flow in only one direction. The spring-loaded design excels at this by using a spring to actively assist the closing mechanism, solving several common issues found in fluid systems.

Preventing Backflow and Water Hammer

The most critical function is preventing reverse flow. When a pump shuts off, the spring's force immediately pushes the disc or poppet back onto its seat, creating a tight seal.

This rapid closure is also controlled, meaning it doesn't slam shut like a traditional swing check valve might. This prevents the damaging pressure surge known as water hammer, which can cause noise, vibration, and stress on pipes and equipment.

Protecting Pumps and Equipment

By preventing backflow, the valve protects the pump from the damaging effects of reverse rotation and pressure spikes. This proactive protection minimizes wear and tear on pump motors, seals, and bearings, extending the life of your critical equipment.

Ensuring System Efficiency

Unchecked reverse flow represents wasted energy, as fluid that has already been moved by the pump is allowed to travel backward. The quick sealing action of a spring-loaded valve traps the fluid downstream, maintaining system pressure and ensuring the energy used by the pump is not lost.

Key Design and Installation Advantages

The physical characteristics of spring-loaded check valves offer significant practical benefits during system design and installation.

Versatile Installation Orientation

Because the closing force is provided by the spring rather than gravity, these valves can be installed in any position—horizontal, vertical upflow, or even vertical downflow. This gives system designers immense flexibility, which is not possible with many other check valve types.

Compact and Lightweight Form Factor

Spring-loaded lift check valves are typically much smaller and lighter than swing check or other equivalent valve types. Their streamlined design makes them the ideal choice for applications where space is limited or where pipe support is a concern.

Quiet and Smooth Operation

The spring-cushioned closing action is inherently quieter than the abrupt closure of a swing check valve. This reduces operational noise and system vibration, which is especially important in commercial buildings or noise-sensitive environments.

Understanding the Trade-offs

While highly effective, spring-loaded valves have characteristics that must be considered for proper application.

Required Cracking Pressure

The spring exerts a constant force that the fluid must overcome to open the valve. This minimum opening pressure is known as cracking pressure. In most systems, this results in a negligible pressure drop, but it can be a factor in extremely low-pressure or gravity-fed applications.

Susceptibility to Debris

The internal components, including the spring and guide, can be more susceptible to fouling or clogging from debris and sediment in the fluid compared to simpler designs like a full-port swing check valve. Proper filtration upstream is often recommended in systems with known particulates.

Potential for Spring Fatigue

Like any mechanical component, the spring can lose tension or fatigue over a long service life. While high-quality valves are designed for millions of cycles, this is a potential long-term maintenance consideration in high-cycle applications.

Making the Right Choice for Your System

Selecting the correct valve depends entirely on the specific demands of your application.

- If your primary focus is installation flexibility in tight spaces: The compact, orientation-independent design of a spring-loaded check valve is unmatched.

- If your primary focus is protecting pumps from water hammer and backflow: The rapid, non-slam closure makes this valve a superior choice for ensuring equipment longevity.

- If your primary focus is a very low-pressure or gravity-fed system: Carefully evaluate the valve's cracking pressure to ensure it does not unacceptably impede flow.

By understanding these core principles, you can confidently select the right valve to ensure your system's reliability and efficiency.

Summary Table:

| Advantage | Benefit |

|---|---|

| Versatile Installation | Can be installed in any orientation (horizontal, vertical up/down) |

| Rapid, Non-Slam Closure | Prevents water hammer and protects pumps from damage |

| Compact & Lightweight | Ideal for applications with limited space |

| Improved System Efficiency | Maintains pressure and prevents energy loss from backflow |

Need high-performance seals or custom PTFE components for your critical fluid systems?

KINTEK specializes in manufacturing precision PTFE seals, liners, and labware for demanding applications in the semiconductor, medical, laboratory, and industrial sectors. Our custom fabrication services—from prototypes to high-volume orders—ensure you get components that meet the exact specifications required for reliable valve and pump performance.

Contact us today to discuss how our solutions can enhance your system's reliability and efficiency!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Teflon Parts Manufacturer PTFE Magnetic Stirring Bar

- Customizable PTFE Scrapers and Shovels for Demanding Applications

People Also Ask

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support