At their core, composite PTFE diaphragms offer the exceptional chemical resistance of PTFE combined with the mechanical strength and flexibility of a rubber backing like EPDM or Viton. This dual-material construction creates a durable, high-performance seal for demanding applications. However, this design introduces limitations, primarily that the diaphragm's overall performance, especially its temperature range, is restricted by the capabilities of the rubber component.

A composite PTFE diaphragm is a specialized solution that solves for both chemical inertness and mechanical flexibility. Its primary disadvantage is that its operational limits are defined by the rubber backing, not the high-performance PTFE face.

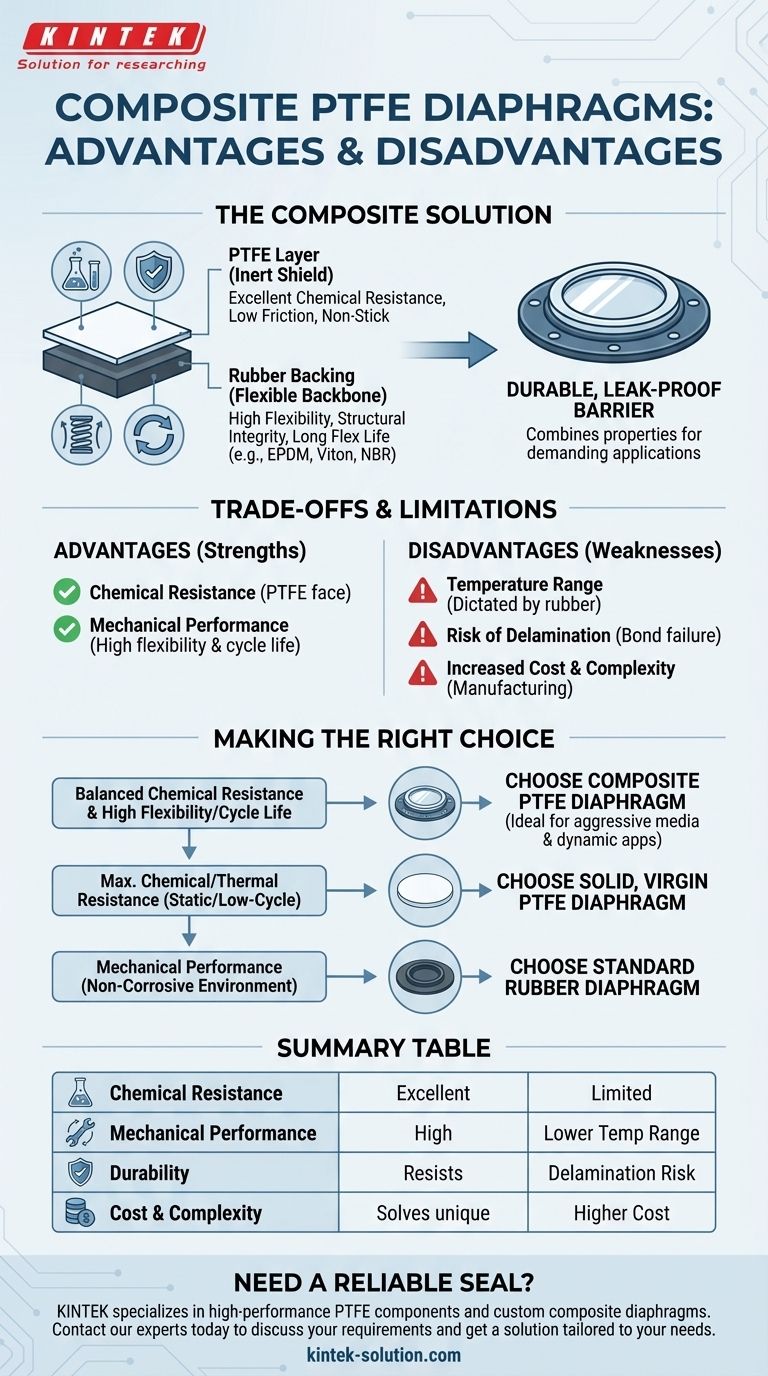

The Principle of a Composite Solution

A composite diaphragm isn't a single material but a strategic combination of two materials, each chosen to contribute a specific, critical property. This design overcomes the inherent weaknesses of using either material alone.

The PTFE Layer: An Inert Chemical Shield

The surface that contacts the process media is a thin layer of Polytetrafluoroethylene (PTFE). This material is chosen for its near-universal chemical inertness.

PTFE is virtually unaffected by acids, bases, solvents, and other aggressive chemicals. Its non-stick, low-friction surface also resists buildup and contamination, ensuring purity.

The Rubber Backing: A Flexible Mechanical Backbone

Bonded to the non-wetted side of the PTFE is a thicker, more resilient rubber diaphragm, typically made of EPDM, Viton, or NBR.

This rubber layer provides the structural integrity, elasticity, and flex life needed to withstand the mechanical stress of actuation over thousands of cycles. Pure PTFE is more rigid and would not perform as well under repeated flexing.

The Result: A Durable, Leak-Proof Barrier

By combining these materials, a composite diaphragm functions as a flexible yet impenetrable barrier. It ensures a tight, reliable seal in applications involving corrosive media, high pressures, or frequent cycling where a single material would fail.

Key Trade-offs and Limitations

While this composite design offers significant advantages, it's crucial to understand the inherent compromises. The performance of the whole is limited by the constraints of its individual parts.

Temperature Range is Dictated by the Rubber

This is the most critical trade-off. While pure PTFE can operate in extreme temperatures (from -250°F to over 500°F), the rubber backing cannot.

The composite diaphragm's maximum and minimum operating temperature is defined by the much narrower range of its rubber component. Exceeding this will cause the rubber to fail, leading to a complete loss of the seal.

The Risk of Delamination

The bond between the PTFE layer and the rubber backing is a potential point of failure. Over time, under chemical attack or mechanical stress, these two dissimilar materials can separate, or delaminate.

Once delamination occurs, the diaphragm is compromised and will fail quickly. The quality of the manufacturing and bonding process is therefore paramount to the diaphragm's reliability.

Increased Manufacturing Complexity and Cost

Creating a reliable bond between PTFE and rubber is a more complex and expensive process than molding a simple, single-material diaphragm.

This increased complexity, including processes like etching the PTFE to improve adhesion, translates to a higher unit cost compared to a standard rubber or even some pure PTFE diaphragms.

Making the Right Choice for Your Application

Selecting the correct diaphragm requires matching the material's capabilities to your specific operational demands.

- If your primary focus is balancing chemical resistance with high flexibility and cycle life: The composite PTFE diaphragm is the ideal choice for handling aggressive media in dynamic applications.

- If your primary focus is maximum chemical and thermal resistance in a static or low-cycle application: A solid, virgin PTFE diaphragm may offer a wider operating window, though with less flexibility.

- If your primary focus is mechanical performance in a non-corrosive environment: A standard rubber diaphragm is the most economical and effective solution.

Ultimately, understanding the composite's strengths and weaknesses empowers you to select a diaphragm that ensures both safety and long-term operational reliability.

Summary Table:

| Aspect | Advantages | Disadvantages |

|---|---|---|

| Chemical Resistance | Excellent (PTFE face) | Limited by rubber backing's chemical compatibility |

| Mechanical Performance | High flexibility and cycle life (rubber backing) | Lower temperature range than pure PTFE |

| Durability | Resists aggressive media and mechanical stress | Risk of delamination at the bond interface |

| Cost & Complexity | Solves unique application challenges | Higher manufacturing cost than single-material diaphragms |

Need a reliable seal for aggressive chemicals and high cycle counts?

At KINTEK, we specialize in manufacturing high-performance PTFE components, including custom composite diaphragms. Our expertise ensures a durable bond between the PTFE layer and rubber backing, maximizing the life and reliability of your seals in semiconductor, medical, laboratory, and industrial applications.

We provide custom fabrication from prototypes to high-volume orders, prioritizing precision to meet your exact specifications.

Contact our experts today to discuss your diaphragm requirements and get a solution tailored to your needs.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

People Also Ask

- When and by whom was PTFE discovered? A Tale of Accidental Innovation

- How is PTFE used in industrial processes? Maximize Safety and Efficiency

- What is the temperature range that PTFE can withstand? From -200°C to +260°C for Demanding Applications

- What are some important physical property values for PTFE? Master Its Extreme Performance for Demanding Applications

- What are some applications of CNC machined PTFE parts? Critical Components for Medical, Electrical & Food Industries