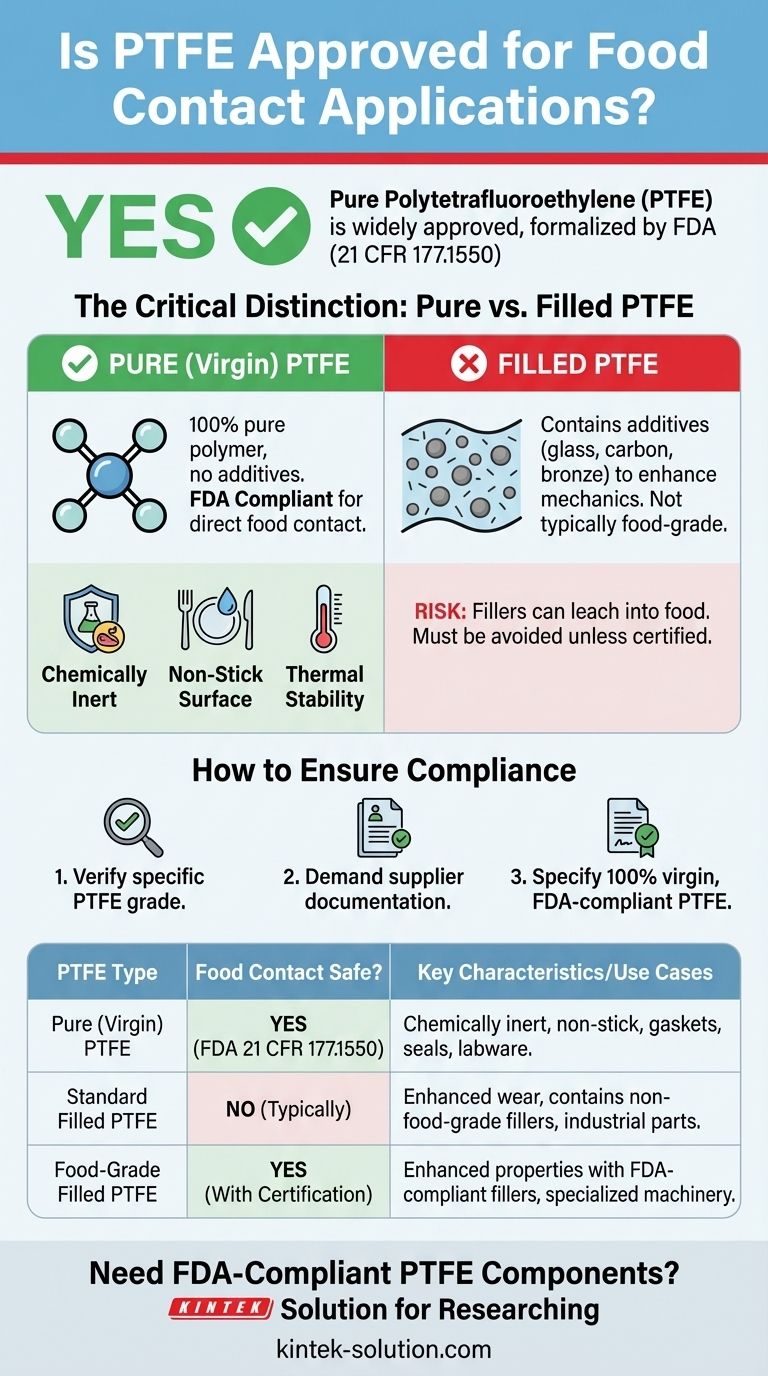

Yes, pure Polytetrafluoroethylene (PTFE) is widely approved for food contact applications. The material is considered safe because it is chemically inert and stable, meaning it does not react with or leach into food products. This approval is formalized by regulatory bodies like the U.S. Food and Drug Administration (FDA).

The critical distinction for food safety is between pure (virgin) PTFE and filled PTFE. While virgin PTFE is FDA-compliant, most filled grades contain additives that are not approved for food contact and must be avoided in these applications.

The Basis for Food Contact Approval

The suitability of PTFE for food processing and handling is rooted in its unique chemical properties. Regulatory bodies have established clear standards based on this inherent safety.

FDA Compliance

The FDA regulates materials that come into contact with food to ensure public safety. PTFE falls under FDA 21 CFR 177.1550 ("Perfluorocarbon Resins").

This regulation specifies that the resin, when used as a food contact surface, must not impart any unsafe substances to the food.

Core Material Properties

PTFE's approval is based on several key characteristics that make it ideal for food environments.

- Chemical Inertness: PTFE is one of the most non-reactive substances known. It does not react with acidic, alkaline, or oily foods, preventing contamination.

- Non-Stick Surface: Its extremely low coefficient of friction creates a non-stick surface. This is invaluable in food processing for preventing buildup and ensuring easy cleaning.

- Thermal Stability: PTFE maintains its integrity across a wide range of temperatures common in cooking and food processing, from freezing to baking.

The Critical Distinction: Pure vs. Filled PTFE

Understanding the grade of PTFE is the single most important factor in determining its suitability for your application. The assumption that all PTFE is food-safe is a common and dangerous mistake.

Why Pure (Virgin) PTFE is Safe

Virgin PTFE is 100% pure polymer without any additives. Because it contains only the inert PTFE resin, it fully complies with FDA standards and can be used in direct contact with food.

The Problem with Filled Grades

PTFE is a relatively soft material. To improve properties like wear resistance, compressive strength, or thermal conductivity, fillers such as glass, carbon, bronze, or stainless steel are added.

These fillers enhance the mechanical performance of the material, making it suitable for demanding industrial applications like bearings or seals.

The Risk of Fillers in Food Applications

The additives used in standard filled PTFE grades are not typically food-grade. These fillers can leach out of the polymer matrix, potentially tainting or discoloring the food and creating a safety hazard.

Therefore, you must never use a standard filled PTFE grade for a food contact application unless it has been specifically certified as food-safe by the manufacturer.

How to Ensure Compliance for Your Application

Making the correct material choice requires verifying the specific grade of PTFE you are sourcing. Always demand documentation from your supplier to ensure safety and compliance.

- If your primary focus is food safety and compliance: Always specify and use 100% virgin, unfilled PTFE that is explicitly certified to meet FDA 21 CFR 177.1550.

- If your application demands enhanced mechanical properties: You must source a specially formulated, food-grade filled PTFE where both the base resin and the filler additive are independently certified as FDA-compliant.

Ultimately, proper material specification is the key to leveraging the benefits of PTFE while guaranteeing the safety of your food application.

Summary Table:

| PTFE Type | Food Contact Safe? | Key Characteristics | Common Use Cases |

|---|---|---|---|

| Pure (Virgin) PTFE | Yes (FDA 21 CFR 177.1550) | Chemically inert, non-stick, thermally stable | Gaskets, seals, labware, non-stick coatings for food processing |

| Standard Filled PTFE | No (Typically) | Enhanced wear resistance, contains non-food-grade additives (glass, carbon) | Industrial bearings, seals, mechanical parts |

| Food-Grade Filled PTFE | Yes (With Certification) | Enhanced properties with FDA-compliant fillers | Food processing machinery requiring high wear resistance |

Need FDA-Compliant PTFE Components for Your Food Application?

KINTEK specializes in manufacturing high-purity, virgin PTFE components (seals, gaskets, liners, custom labware) that are fully compliant with FDA 21 CFR 177.1550 for food contact. We ensure material traceability and provide the necessary documentation for your peace of mind.

Let us help you ensure safety and compliance:

- Precision Production: We prioritize manufacturing precision for reliable performance.

- Custom Fabrication: From prototypes to high-volume orders, we tailor solutions for the semiconductor, medical, laboratory, and industrial sectors.

- Expert Guidance: Our team can help you select the correct, certified material for your specific needs.

Contact KINTEK today to discuss your project requirements and receive a quote for food-safe PTFE components.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Bottles for Diverse Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Customizable PTFE Crucibles for Laboratory and Industrial Applications

People Also Ask

- What standards are available for PTFE gaskets? Selecting the Right Standard for Reliable Sealing

- Why is PTFE's biological inertia beneficial for medical use? Ensure Implant Safety and Longevity

- What material are PTFE heat press sheets made from? Unlock Consistent, Professional Results

- What are the key features of Teflon balls? Unlock Superior Performance in Demanding Environments

- Why is PTFE used as a lining material in these valves? For Unmatched Chemical Resistance and Reliability

- How does the low coefficient of friction of PTFE gaskets benefit their performance? Extend Equipment Life & Efficiency

- What machining processes are suitable for Teflon/PTFE? Master Precision Machining for Soft Materials

- Are PTFE coating thrust washers suitable for all types of fishing reels? Matching Performance to Your Angling Needs