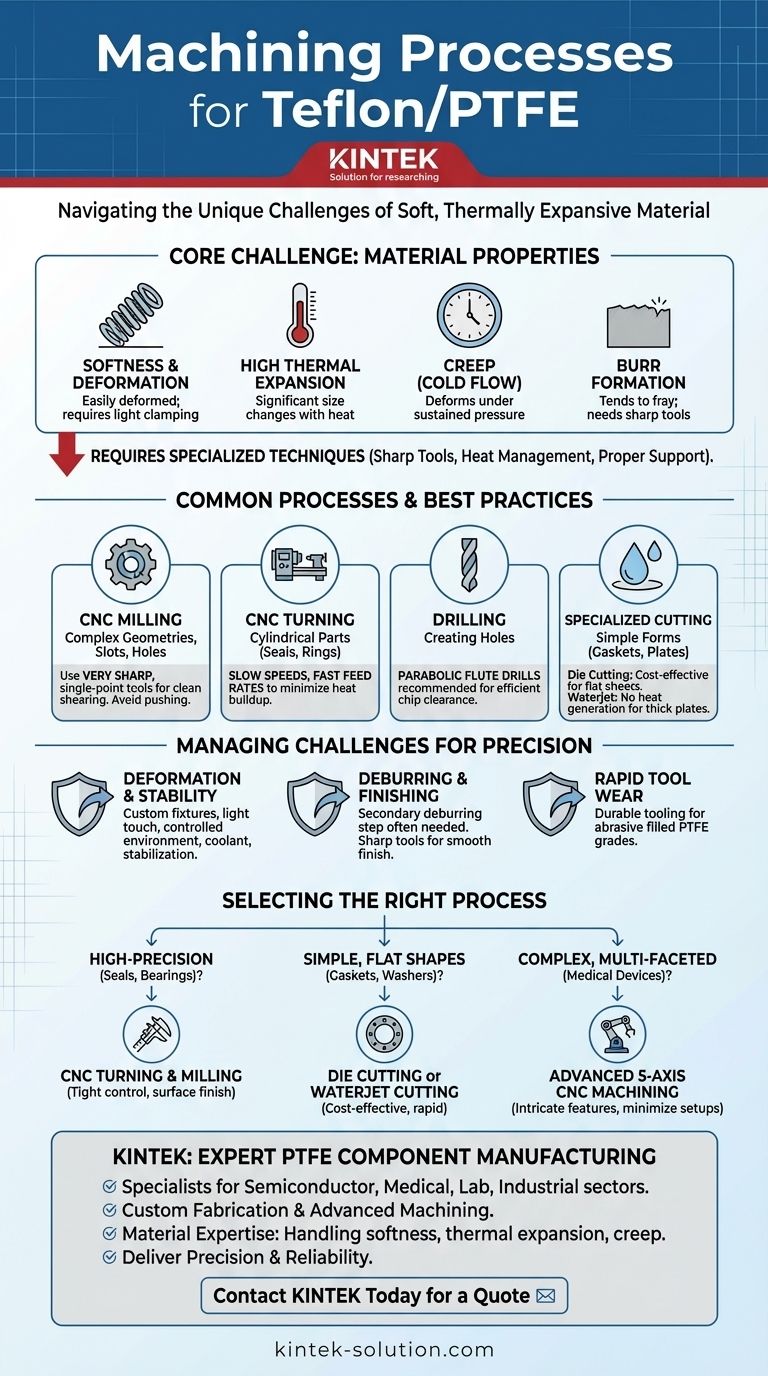

Virtually all standard machining processes can be adapted for Teflon (PTFE), but success requires specialized techniques to manage the material's unique properties. The most common methods include CNC milling, turning, and drilling, with processes like waterjet and die cutting used for specific forms like sheets and plates.

The core challenge in machining Teflon is not a lack of compatible processes, but rather controlling its inherent softness, low mechanical strength, and high thermal expansion. Success depends entirely on using extremely sharp tools, managing heat, and providing proper support to prevent deformation and ensure dimensional accuracy.

Why Teflon Demands a Specialized Approach

Teflon’s valuable properties—low friction, chemical inertness, and temperature resistance—are a direct result of its unique molecular structure. These same properties, however, make it a uniquely challenging material to machine with precision.

Low Mechanical Strength

PTFE is a soft material that can easily be deformed or compressed by cutting forces or clamping pressure. This requires careful workholding and tool paths to avoid distorting the final part.

High Thermal Expansion

The material expands and contracts significantly with temperature changes. Heat generated during machining can cause the part to swell, leading to inaccurate cuts that will be out of tolerance once the part cools.

Tendency to Creep (Cold Flow)

Under sustained pressure, even at room temperature, PTFE will slowly deform. This "creep" or "cold flow" means that excessive clamping pressure can permanently alter the part's dimensions before a single cut is made.

Burr Formation

Due to its softness, Teflon tends to form burrs during machining rather than creating a clean chip. This necessitates extremely sharp cutting tools and specific tool geometries to achieve a clean finish.

Common Machining Processes for PTFE

While many processes are viable, they must be adapted to address the material's characteristics. The use of CNC machining is highly recommended for its precision and control.

CNC Milling

Milling is effective for creating complex geometries, slots, and holes. The key is to use very sharp, single-point cutting tools to shear the material cleanly rather than pushing it.

CNC Turning

Turning is ideal for producing cylindrical parts like seals, rings, and rollers. Machinists often use slow speeds combined with fast feed rates to minimize heat buildup and reduce tool contact time.

Drilling

Standard drills can cause significant heat and deformation. Parabolic flute drills are often recommended as their shape is more efficient at clearing chips and reducing friction.

Specialized Cutting Methods

For simpler or specific forms, other methods are highly efficient. Die cutting is excellent for producing gaskets and other thin, flat parts from PTFE sheets, while waterjet cutting can process thicker plates without generating heat.

Understanding the Trade-offs and Challenges

Machining Teflon is a balance of precision and control. Without understanding the potential pitfalls, it is easy to produce parts that are out of tolerance and functionally useless.

Risk of Deformation

The primary challenge is preventing the part from deforming under clamping and cutting forces. This requires custom fixtures and a light touch, which can increase setup time and cost.

Managing Dimensional Stability

Because of its high thermal expansion, a controlled environment and the use of coolant are often necessary. Parts must be allowed to stabilize at a standard temperature before final inspection to ensure accuracy.

Deburring and Finishing

Parts often require a secondary deburring step, which adds time and labor to the process. Achieving a perfectly smooth surface finish requires sharp tools and optimized cutting parameters.

Rapid Tool Wear

While soft, some grades of filled PTFE (e.g., glass-filled) are highly abrasive and can cause rapid tool wear. This necessitates the use of durable tooling and frequent tool changes.

Making the Right Choice for Your Application

Selecting the right process depends entirely on the complexity of your part and the required tolerances.

- If your primary focus is high-precision components (seals, bearings, insulators): CNC turning and milling are the best choices, as they offer the tightest control over dimensions and surface finish.

- If your primary focus is simple, flat shapes (gaskets, washers): Die cutting or waterjet cutting offers a highly cost-effective and rapid solution for producing parts from sheet material.

- If your primary focus is complex, multi-faceted parts (medical devices, semiconductor components): Advanced 5-axis CNC machining is necessary to create intricate features while minimizing setups and handling to maintain accuracy.

By understanding Teflon's unique behavior and pairing it with the correct machining strategy, you can successfully leverage its exceptional properties for your most demanding applications.

Summary Table:

| Process | Best For | Key Consideration |

|---|---|---|

| CNC Milling | Complex geometries, slots, holes | Use sharp, single-point tools to shear material cleanly |

| CNC Turning | Cylindrical parts (seals, rings) | Slow speeds with fast feed rates to manage heat |

| Drilling | Creating holes | Parabolic flute drills recommended for efficient chip clearance |

| Die Cutting | Simple, flat shapes (gaskets) | Cost-effective for high-volume sheet parts |

| Waterjet Cutting | Thick plates | No heat-affected zone; ideal for heat-sensitive applications |

Need Precision-Machined PTFE Components?

KINTEK specializes in manufacturing high-quality PTFE components for the semiconductor, medical, laboratory, and industrial sectors. We understand the unique challenges of machining Teflon and leverage advanced techniques to ensure dimensional accuracy and superior performance in every part.

Our capabilities include:

- Custom Fabrication: From prototypes to high-volume production runs.

- Advanced Machining: Expert CNC milling, turning, and drilling for complex geometries.

- Material Expertise: Precise handling of PTFE's softness, thermal expansion, and creep.

Let us deliver the precision and reliability your application demands.

Contact KINTEK today for a quote and see how our expertise can benefit your project.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers