To be direct, PTFE-coated thrust washers are suitable for the most common types of fishing reels, including spinning, baitcasting, and conventional models. However, their universal suitability is not guaranteed. The decision to use them depends less on the type of reel and more on the specific performance demands and environmental conditions you face.

The core issue isn't whether a PTFE washer can fit, but whether its benefits—primarily reduced friction and corrosion resistance—align with your specific fishing needs and your reel's design.

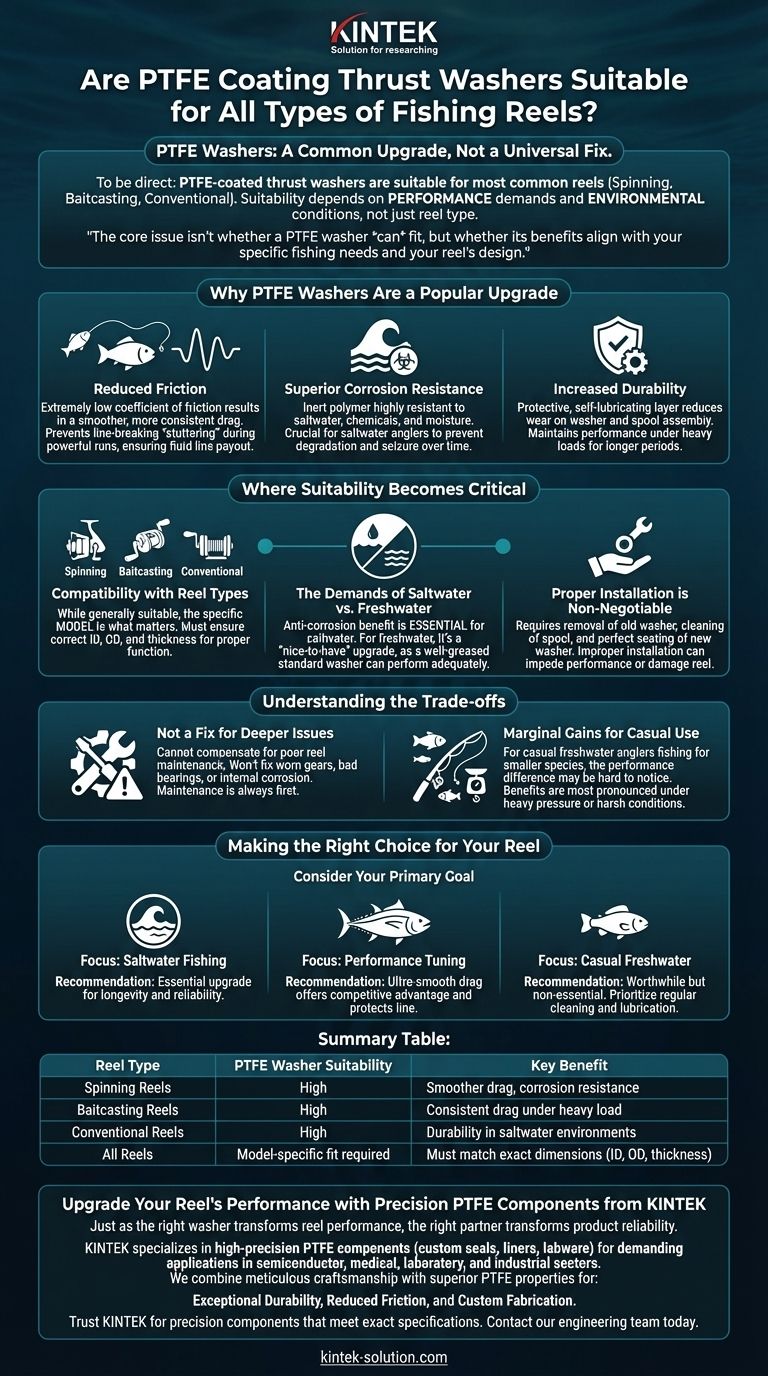

Why PTFE Washers Are a Popular Upgrade

Enthusiasts often upgrade to PTFE (Polytetrafluoroethylene) washers because they offer tangible performance improvements over standard factory components, which are often made of simpler materials.

The Core Benefit: Reduced Friction

The defining characteristic of PTFE is its extremely low coefficient of friction. In a fishing reel, this translates directly to a smoother, more consistent drag system.

When a powerful fish runs, a smoother drag pays out line without the stuttering or "sticking" that can cause a line to break. This also contributes to a more fluid feel when casting and retrieving.

Superior Corrosion Resistance

PTFE is an inert polymer, making it highly resistant to corrosion from saltwater, chemicals, and moisture. This is arguably its most critical advantage.

For anglers who frequently fish in saltwater environments, this resistance prevents the degradation and seizure that can plague standard metal or fiber washers over time.

Increased Durability

The PTFE coating acts as a protective, self-lubricating layer. It reduces the wear and tear on the washer and the adjoining parts of the spool assembly.

This resilience means the washer maintains its performance characteristics for a longer period, especially under the heavy loads of fighting large fish.

Where Suitability Becomes Critical

While the benefits are clear, simply swapping in a PTFE washer is not always a guaranteed improvement. The context of its use is what determines its true value.

Compatibility with Reel Types

While PTFE washers are made for spinning, baitcasting, and conventional reels, the specific model is what matters. You must ensure the aftermarket washer has the correct dimensions (inner diameter, outer diameter, and thickness) for your specific reel to function correctly.

The Demands of Saltwater vs. Freshwater

The anti-corrosion benefit of PTFE is a significant factor for saltwater anglers. In freshwater, where corrosion is less of an immediate threat, a standard, well-greased washer can perform adequately. The upgrade becomes less critical and more of a "nice-to-have" for smoothness.

Proper Installation is Non-Negotiable

A PTFE washer will only perform as intended if installed correctly. The old washer must be removed, the spool surface cleaned of any old grease or debris, and the new washer seated perfectly flat before reassembly. An improperly seated washer can impede performance or damage the reel.

Understanding the Trade-offs

An upgrade is only an upgrade if it solves a real problem. Objectively, there are situations where a PTFE washer may not be the right solution.

Not a Fix for Deeper Issues

A high-performance washer cannot compensate for a poorly maintained reel. If your reel has worn gears, bad bearings, or internal corrosion, a new washer will not fix these underlying problems. Maintenance is always the first step.

Marginal Gains for Casual Use

For a casual angler fishing for smaller species in freshwater, the performance difference between a new PTFE washer and a clean, properly lubricated stock washer may be difficult to notice. The benefits are most pronounced under heavy, sustained drag pressure or in harsh, corrosive environments.

Making the Right Choice for Your Reel

To determine if this upgrade is right for you, consider your primary goal.

- If your primary focus is saltwater fishing: The corrosion resistance of PTFE makes it an almost essential upgrade for equipment longevity and reliability.

- If your primary focus is performance tuning for large fish: The ultra-smooth drag provided by PTFE can offer a competitive advantage and protect your line from sudden breaks.

- If your primary focus is casual freshwater angling: This is a worthwhile but non-essential upgrade. Prioritize regular cleaning and lubrication of your existing components first.

Ultimately, choosing the right components is about matching the technology to your specific application.

Summary Table:

| Reel Type | PTFE Washer Suitability | Key Benefit |

|---|---|---|

| Spinning Reels | High | Smoother drag, corrosion resistance |

| Baitcasting Reels | High | Consistent drag under heavy load |

| Conventional Reels | High | Durability in saltwater environments |

| All Reels | Model-specific fit required | Must match exact dimensions (ID, OD, thickness) |

Upgrade Your Reel's Performance with Precision PTFE Components from KINTEK

Just as the right thrust washer can transform your fishing reel's performance, the right manufacturing partner can transform your product's reliability. KINTEK specializes in high-precision PTFE components—including custom seals, liners, and labware—for demanding applications in the semiconductor, medical, laboratory, and industrial sectors.

We combine meticulous craftsmanship with the superior material properties of PTFE to deliver components that offer:

- Exceptional Durability: Withstand harsh chemicals and extreme environments.

- Reduced Friction: For smoother operation and longer service life.

- Custom Fabrication: From initial prototypes to high-volume production runs.

Whether you're designing critical medical devices or specialized industrial equipment, trust KINTEK to manufacture PTFE components that meet your exact specifications. Contact our engineering team today to discuss your project requirements and discover how our precision components can enhance your product's performance.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Bottles for Diverse Industrial Applications

- PTFE Chemical Solvent Sampling Spoon

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers