At its core, Polytetrafluoroethylene (PTFE) is used to line valves because it creates an incredibly resilient, non-reactive barrier. This lining provides exceptional protection against highly corrosive chemicals, prevents material buildup due to its non-stick nature, and tolerates a wide range of temperatures, ensuring the valve operates reliably in demanding industrial environments.

The primary value of a PTFE lining is its chemical inertness, which isolates the valve's core metal components from corrosive media. This chemical resistance, combined with its extremely low friction, makes it one of the most reliable and versatile solutions for handling aggressive fluids.

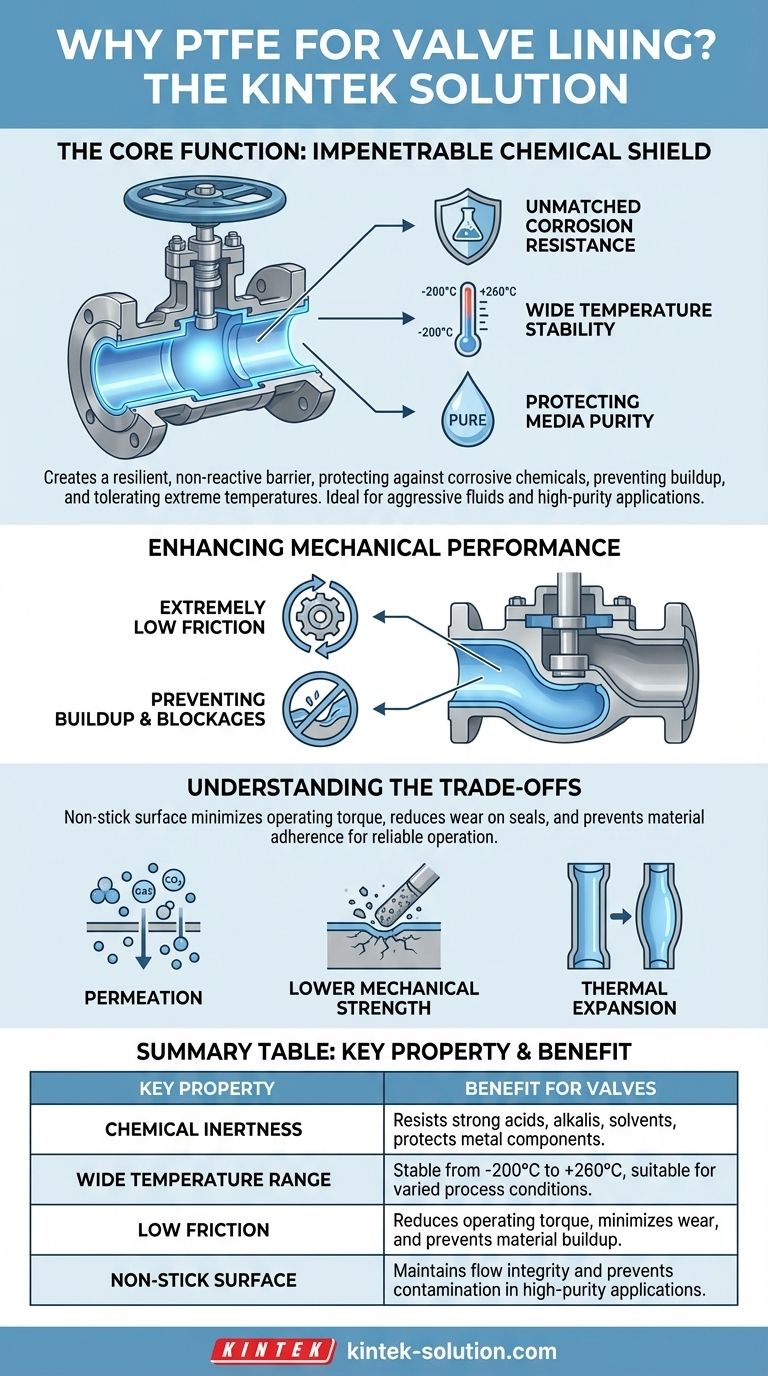

The Core Function: An Impenetrable Chemical Shield

The fundamental reason for using a PTFE liner is to protect the structural components of a valve, which are typically made of metal, from the fluid passing through it. This is achieved through several key properties.

Unmatched Corrosion Resistance

PTFE is virtually inert to almost all industrial chemicals. It provides steadfast protection against strong acids, alkalis, solvents, and other highly corrosive media that would quickly degrade most metals.

Wide Temperature Stability

Industrial processes rarely occur at room temperature. PTFE maintains its integrity and protective properties across an exceptionally broad temperature range, typically from -200°C to +260°C (-328°F to +500°F).

Protecting Media Purity

Because PTFE is so non-reactive, it does not leach or contaminate the fluid passing through it. This makes it a standard material in industries like food and beverage, pharmaceuticals, and electronics, where product purity is critical.

Beyond Resistance: Enhancing Mechanical Performance

While chemical protection is the primary goal, a PTFE lining also significantly improves the valve's operational mechanics and longevity.

The Power of Extremely Low Friction

PTFE has one of the lowest coefficients of friction of any solid material. This "non-stick" quality is vital in valves with moving parts, such as ball or plug valves.

This ultra-low friction surface reduces the torque required to open and close the valve, minimizing wear on seals and rotational components and extending the equipment's lifespan.

Preventing Buildup and Blockages

The non-stick surface also prevents the process media from adhering to the valve's internal surfaces. This is crucial for fluids that are sticky, contain suspended solids, or have a tendency to crystallize, ensuring a clear flow path and consistent performance.

Understanding the Trade-offs

While highly effective, PTFE is not without its limitations. An objective assessment requires acknowledging its trade-offs compared to solid metal or other lining materials.

Susceptibility to Permeation

Although PTFE is a robust barrier, it is still a polymer. Highly aggressive, small-molecule gases (like chlorine or hydrogen) can, over time and at elevated temperatures, slowly permeate the lining and potentially corrode the valve body behind it.

Lower Mechanical Strength

Compared to metal, PTFE is a relatively soft material. It can be damaged by high-velocity, abrasive media (like sharp-edged slurries) or extreme mechanical stress, which can lead to scoring or deformation of the lining.

Thermal Expansion

PTFE has a higher coefficient of thermal expansion than metal. Valve designs must account for this difference to ensure the liner remains perfectly sealed against the valve body during temperature fluctuations.

Making the Right Choice for Your Application

Selecting the right valve is about matching the material to the specific demands of the process.

- If your primary focus is handling highly corrosive media: A PTFE-lined valve is an industry-standard choice, offering superior protection for the valve's structural components at a lower cost than exotic metal alloys.

- If your process involves high-purity or sanitary requirements: PTFE's inert, non-stick surface prevents contamination, making it ideal for food-grade, pharmaceutical, or electronics manufacturing applications.

- If your media contains abrasive solids or operates at extreme pressures: You must verify that the specific valve design and lining thickness are engineered to withstand potential mechanical damage.

By understanding these core properties and trade-offs, you can confidently specify PTFE-lined valves for applications where chemical resilience and operational reliability are paramount.

Summary Table:

| Key Property | Benefit for Valves |

|---|---|

| Chemical Inertness | Resists strong acids, alkalis, and solvents, protecting metal components |

| Wide Temperature Range | Stable from -200°C to +260°C, suitable for varied process conditions |

| Low Friction | Reduces operating torque, minimizes wear, and prevents material buildup |

| Non-Stick Surface | Maintains flow integrity and prevents contamination in high-purity applications |

Need a reliable PTFE-lined valve solution for your demanding process? KINTEK specializes in manufacturing high-performance PTFE components—including custom seals, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors. Whether you require prototypes or high-volume orders, our precision production ensures your equipment operates safely and efficiently. Contact us today to discuss your specific requirements!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

People Also Ask

- What are the advantages of square rings over O-rings in static applications? Achieve Superior High-Pressure Sealing

- What are PTFE-lined plug valves and their primary purpose? Achieve Superior Control for Corrosive & High-Purity Fluids

- What temperature limitation should be considered for PTFE ball valves? Maintain a Reliable Seal Under Thermal Stress

- In which industries are Teflon O-rings commonly used? Sealing Solutions for Extreme Conditions

- How did PTFE lined butterfly valves address corrosion resistance challenges? Provide a Robust Barrier Against Corrosive Media

- What makes Teflon (PTFE) suitable for food handling equipment? Discover its Safety & Efficiency Benefits

- How is PTFE used in the semi-conductor industry? Essential for Purity and Performance

- How is a piston seal constructed? A Guide to Dynamic, Pressure-Energized Sealing