In short, spring-energized PTFE seals are used in nearly every industry where standard elastomer seals fail. Their most common applications are in Oil & Gas, Aerospace, Medical and Pharmaceutical, Automotive, and Chemical Processing due to their unique ability to handle extreme operating conditions.

The core reason these seals are so widely adopted is their fundamental design: a durable, low-friction PTFE jacket combined with a spring energizer. This pairing creates a reliable seal in environments with extreme temperatures, high pressures, or aggressive chemicals where conventional seals would degrade or lose their sealing force.

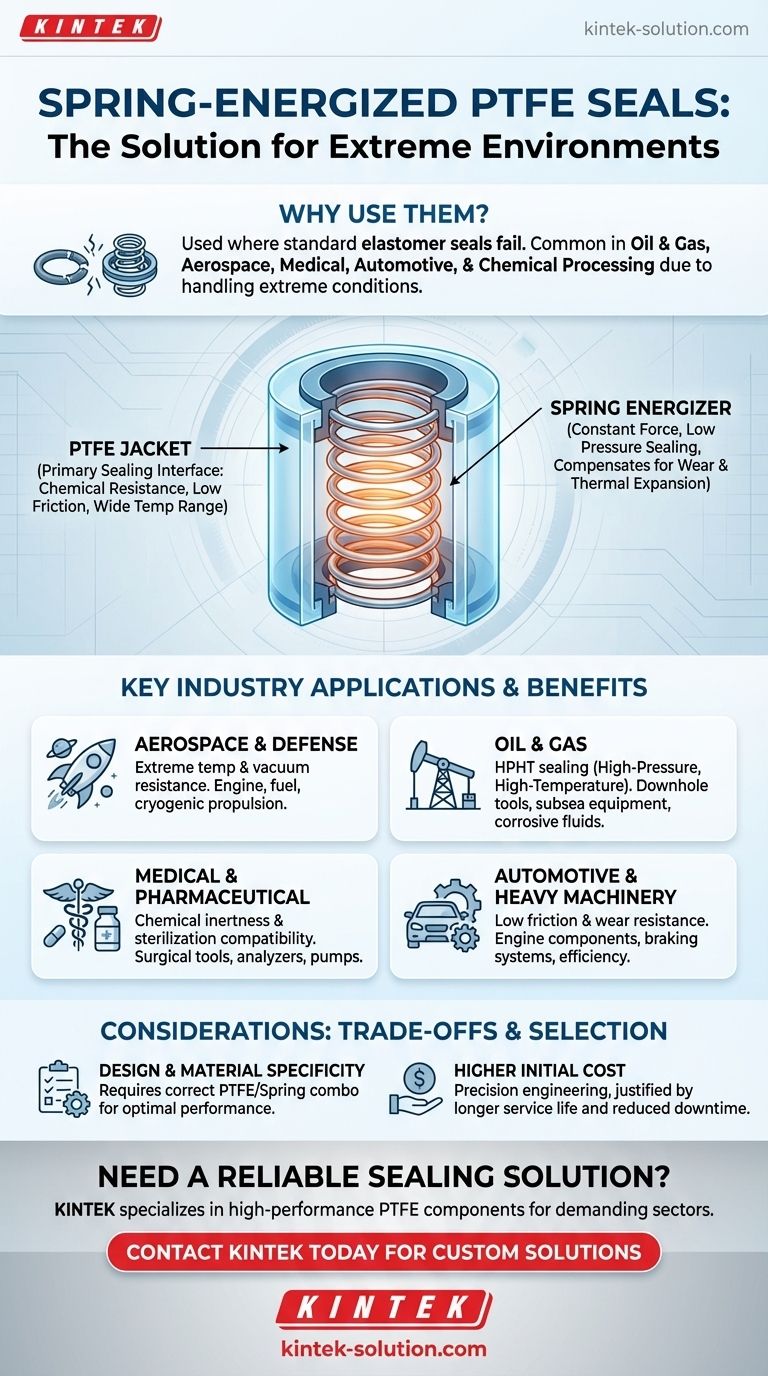

What Makes a Spring-Energized PTFE Seal Unique?

To understand why these seals are critical in such demanding fields, you must first understand how their two core components work together to solve complex sealing challenges.

The Role of the PTFE Jacket

Polytetrafluoroethylene (PTFE) is a high-performance polymer that provides the primary sealing interface. Its properties make it ideal for aggressive environments.

Key characteristics include exceptional chemical resistance against corrosive substances, a very low coefficient of friction which reduces wear and energy loss, and the ability to operate across a vast temperature range.

The Function of the Spring Energizer

Unlike a standard O-ring that relies on system pressure and its own elasticity, this seal uses a metal spring (like a cantilever or canted coil spring) embedded within the PTFE jacket.

This spring exerts a constant, uniform force against the sealing lip. This ensures a tight seal even at low pressures, compensates for thermal expansion and contraction, and accounts for wear over the seal's lifespan.

A Closer Look at Key Industrial Applications

The combination of a resilient PTFE jacket and a constant-force spring makes these seals the definitive solution for specific, high-stakes applications across various sectors.

Aerospace and Defense

In aerospace, failure is not an option. These seals are used in aircraft engines, hydraulic actuators, fuel systems, and cryogenic propulsion lines.

They are specified for their ability to withstand extreme temperature variations, from cryogenic fuels to high-engine heat, as well as the vacuum of high altitudes. Their low outgassing properties are also critical for space applications.

Oil and Gas

The oil and gas industry presents some of the harshest operating conditions, characterized by high-pressure, high-temperature (HPHT) environments.

Spring-energized seals are essential in downhole tools, subsea equipment, valves, and pumps. They reliably seal against abrasive and corrosive fluids, preventing catastrophic leaks in equipment that is difficult and costly to service.

Medical and Pharmaceutical

Purity and reliability are paramount in medical and food-grade applications. These seals are chosen for their non-toxic and non-stick properties.

They are used in surgical tools, hematology analyzers, pumps, and mixers where they must withstand aggressive sterilization processes and disinfectants without degrading or contaminating the process media.

Automotive and Heavy Machinery

In automotive and construction equipment, the focus is on durability, efficiency, and performance. Applications include engine components, transmissions, and braking systems.

The seals provide excellent wear resistance and their low-friction nature helps minimize energy loss, contributing to better fuel efficiency and longer component life in machinery like excavators and loaders.

Understanding the Trade-offs

While highly effective, spring-energized PTFE seals are a specialized component, and their application requires careful consideration.

Design and Material Specificity

The performance of the seal is entirely dependent on choosing the correct combination of PTFE compound, filler material, and spring type for the specific application.

An incorrect specification can lead to suboptimal performance. For example, a spring with too much force can cause excessive wear, while the wrong PTFE blend may not be compatible with the process fluid.

Higher Initial Cost

As a precision-engineered solution, these seals typically have a higher upfront cost compared to standard elastomeric seals like O-rings.

However, this cost is often justified by their significantly longer service life, reduced downtime, and ability to perform in conditions where less expensive seals would fail immediately.

Making the Right Choice for Your Application

Selecting the appropriate seal requires aligning its material properties with the primary challenge of your operating environment.

- If your primary focus is extreme temperatures and pressures (e.g., Oil & Gas, Aerospace): Ensure the spring material and PTFE grade are specified to handle the full thermal and pressure range without failure.

- If your primary focus is chemical inertness and purity (e.g., Medical, Food Processing): Prioritize biocompatible or FDA-compliant PTFE grades and a design that eliminates dead space to prevent contamination.

- If your primary focus is high wear resistance and low friction (e.g., Automotive, Industrial): Evaluate filled PTFE compounds that enhance durability and select a spring design that provides optimal lip loading for longevity.

Ultimately, a spring-energized PTFE seal is an engineering solution for sealing problems that cannot be solved by conventional means.

Summary Table:

| Industry | Primary Application | Key Seal Benefit |

|---|---|---|

| Aerospace & Defense | Aircraft engines, fuel systems | Extreme temperature & vacuum resistance |

| Oil & Gas | Downhole tools, subsea equipment | High-pressure, high-temperature (HPHT) sealing |

| Medical & Pharmaceutical | Surgical tools, analyzers | Chemical inertness & sterilization compatibility |

| Automotive & Heavy Machinery | Engine components, braking systems | Low friction & wear resistance |

| Chemical Processing | Valves, pumps | Resistance to corrosive media |

Need a Reliable Sealing Solution for Demanding Environments?

Spring-energized PTFE seals are precision components designed to perform where standard seals fail. At KINTEK, we specialize in manufacturing high-performance PTFE components—including custom seals, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors.

We understand that every application has unique challenges. Whether you require prototypes or high-volume production, our team ensures precision manufacturing and material expertise to deliver seals that withstand extreme temperatures, aggressive chemicals, and high pressures.

Let us help you solve your toughest sealing problems. Contact KINTEB today to discuss your custom PTFE component needs!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE and Nitrile Diaphragm Pump Components for Demanding Applications

People Also Ask

- What are the key properties that make Teflon rods suitable for industrial applications? Unlock Unmatched Chemical & Thermal Resistance

- What are the components of an assembly PTFE sliding bearing pad? A Guide to the Engineered System

- What are the properties of Modified Polytetrafluoroethylene? Enhanced Performance for Demanding Applications

- What specific advantages do PTFE coated bolts and screws offer? Achieve Reliable, Seizure-Free Assemblies

- What are the key properties of PTFE O-rings? Unlock Superior Chemical & Thermal Resistance

- Why is UV resistance important for PTFE Teflon washers? Ensure Long-Term Reliability in Outdoor and Harsh Environments

- What are the advantages of PTFE-lined pipes? Achieve Unmatched Corrosion Resistance and Purity

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability