The fundamental difference is that machining Teflon (PTFE) is a process of managing softness and preventing heat buildup, while machining metal is a process of overcoming rigidity and managing immense cutting forces. You machine Teflon with finesse, using surgically sharp tools at low speeds to avoid melting it; you machine metal with power, using robust tools to shear a much harder material.

While both processes involve removing material, they are governed by opposing principles. Success with metals hinges on rigidity and power to withstand high forces, whereas success with Teflon depends entirely on sharp tooling, low stress, and heat prevention to avoid deforming or melting the soft material.

The Core Material Differences

The distinct properties of Teflon and metals dictate every aspect of the machining process, from tooling and speeds to how you hold the workpiece.

Metals: High Rigidity and Thermal Stability

Metals are rigid, crystalline structures. To cut them, you must exert enough force to exceed their shear strength.

This requires powerful, rigid machines and tooling that can withstand immense pressure and vibration without deflecting. Heat is a byproduct, but metals generally have high melting points and good thermal conductivity, dissipating heat away from the cutting zone.

Teflon (PTFE): Low Rigidity and Thermal Sensitivity

Teflon is a soft polymer with a very low coefficient of friction. Instead of resisting force, it prefers to deform or push away from it.

It also has a very low melting point and is a poor thermal conductor. This means any heat generated by friction stays right at the cutting edge, quickly leading to melting, gumming up the tool, and a failed part.

Managing Heat: The Primary Challenge

Heat is the central enemy when machining Teflon. The entire strategy revolves around preventing its generation in the first place.

The Problem with Heat and Teflon

Because Teflon doesn't conduct heat well, the friction from a cutting tool creates an intense, localized temperature spike. This instantly melts the material, resulting in a gummy, poor surface finish and inaccurate dimensions.

Metal's Approach to Heat

In metal machining, coolant is primarily used to preserve the life of the cutting tool and prevent the workpiece from expanding too much. The metal workpiece itself can typically absorb a significant amount of heat without melting.

Teflon's Approach to Heat

The strategy for Teflon is heat prevention. This is achieved through a combination of factors:

- Extremely sharp tools to shear cleanly with minimal friction.

- Lower cutting speeds to reduce the rate of frictional heat buildup.

- Minimal feed rates to reduce pressure on the material.

- Ample coolant to immediately carry away what little heat is generated.

Tooling and Parameters: A Strategy of Finesse

The tools and settings used for Teflon are fundamentally different from those used for most metals.

The Need for Surgical Sharpness

A tool that is considered sharp enough for aluminum will likely just rub and melt Teflon. Tools for Teflon must have a very sharp, polished cutting edge and high positive rake angles to slice the material cleanly, much like a sharp knife cutting through a soft tomato.

Lower Speeds and Feeds

While machinists often increase speeds to improve cycle times in metals, doing so with Teflon is a recipe for failure. Low cutting speeds and low feed rates are non-negotiable. They minimize friction, which is the primary source of heat.

Workholding and Clamping

Metals can be clamped tightly in a vise with little risk of damage. Clamping Teflon with the same force will crush or deform it, ruining the part before the first cut is even made. It requires minimal, carefully applied clamping pressure.

Common Pitfalls to Avoid

Understanding the differences helps you avoid the most common mistakes machinists make when transitioning from metals to plastics.

Mistake 1: Using a "Good Enough" Tool

A slightly worn tool will plow through Teflon instead of cutting it. This rubbing action generates massive amounts of heat, leading to a melted, unusable surface. Always use your sharpest tooling.

Mistake 2: Overtightening the Vise

Technicians accustomed to cranking down on a vise to hold steel will easily destroy a Teflon workpiece. The material's softness means it must be held with just enough pressure to secure it, and no more.

Mistake 3: Ignoring Thermal Expansion

Because Teflon is sensitive to temperature changes, a part can be perfectly in-spec while it's warm from machining but fall out of tolerance as it cools to room temperature. For high-precision parts, temperature normalization is critical.

Making the Right Choice for Your Goal

Your machining strategy must adapt to the unique properties of Teflon to achieve a successful outcome.

- If your primary focus is dimensional accuracy: You must use minimal clamping pressure and allow the material to stabilize at room temperature before taking final measurements.

- If your primary focus is a clean surface finish: You must use exceptionally sharp tools with a high positive rake and a constant flood of coolant to prevent any localized melting.

- If your primary focus is avoiding part deformation: You must use low cutting speeds and feed rates to minimize both tool pressure and heat input into the workpiece.

Ultimately, successful Teflon machining requires a shift in mindset from applying force to applying finesse.

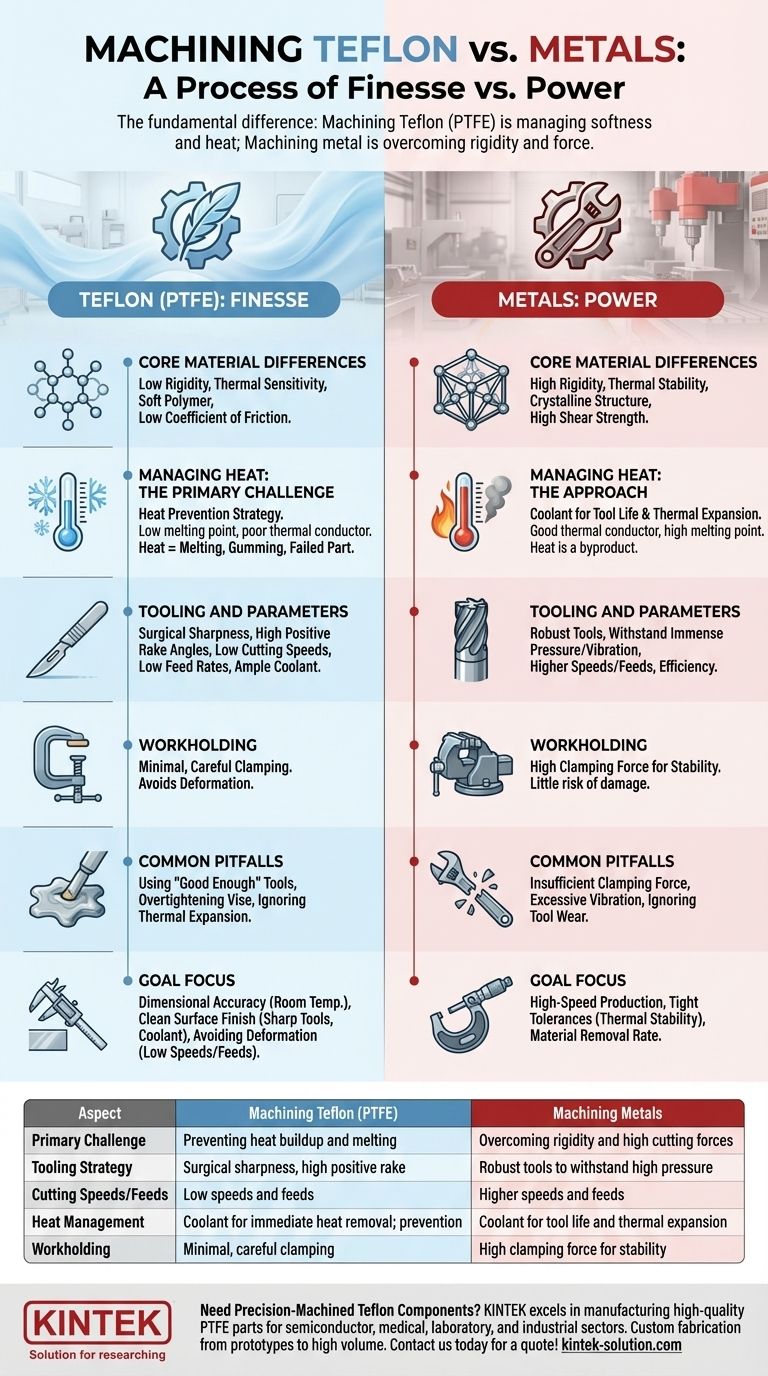

Summary Table:

| Aspect | Machining Teflon (PTFE) | Machining Metals |

|---|---|---|

| Primary Challenge | Preventing heat buildup and melting | Overcoming rigidity and high cutting forces |

| Tooling Strategy | Surgical sharpness, high positive rake angles | Robust tools to withstand high pressure |

| Cutting Speeds/Feeds | Low speeds and feeds to minimize friction | Higher speeds and feeds for efficiency |

| Heat Management | Coolant for immediate heat removal; prevention is key | Coolant for tool life and thermal expansion control |

| Workholding | Minimal, careful clamping to avoid deformation | High clamping force for stability |

Need Precision-Machined Teflon Components?

Machining Teflon requires specialized expertise to avoid common pitfalls like melting and deformation. KINTEK excels in manufacturing high-quality PTFE components (seals, liners, labware, etc.) for the semiconductor, medical, laboratory, and industrial sectors. We prioritize precision production and offer custom fabrication from prototypes to high-volume orders, ensuring your parts meet exact specifications.

Let our expertise work for you. Contact us today for a quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech