Polytetrafluoroethylene (PTFE) is considered an ideal material for demanding hydraulic and pneumatic applications because its unique combination of properties directly solves the most common failure points in these systems. Its exceptional chemical resistance, extremely low coefficient of friction, and broad temperature tolerance allow it to outperform traditional elastomeric seals in harsh and critical operating conditions.

The true value of PTFE is not just one of its properties, but their synergistic effect. It creates reliable, long-lasting seals and components that maintain their integrity under extreme chemical, thermal, and mechanical stress, which translates directly to enhanced system safety, efficiency, and longevity.

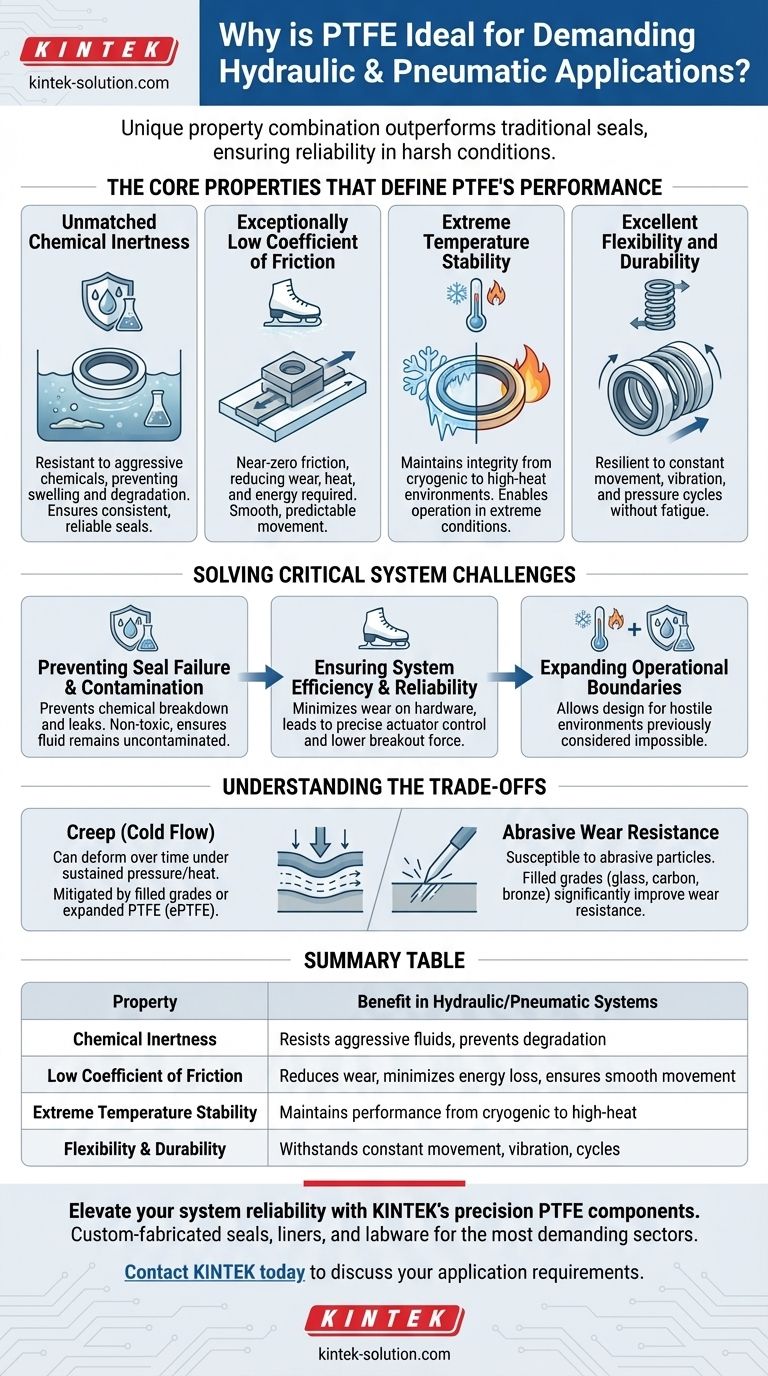

The Core Properties That Define PTFE's Performance

To understand why PTFE is so effective, we must first examine its fundamental material characteristics. Each property addresses a specific vulnerability found in high-performance fluid power systems.

Unmatched Chemical Inertness

PTFE is resistant to nearly all industrial chemicals, including aggressive acids, bases, solvents, and salts. This non-reactive nature is critical in hydraulic and pneumatic systems where specialized fluids or contaminants could easily degrade lesser materials.

This inertness prevents the seal or component from swelling, hardening, or dissolving over time, ensuring a consistent and reliable seal throughout its service life.

An Exceptionally Low Coefficient of Friction

PTFE has one of the lowest coefficients of friction of any solid material, often compared to wet ice on wet ice. This "slipperiness" is a significant advantage in dynamic applications like actuator rods and valve stems.

This property means that parts can slide against each other with minimal resistance, which reduces heat generation, minimizes wear, and lowers the energy required to operate the system. It ensures smooth, predictable movement without the "stick-slip" behavior that can plague systems with elastomeric seals.

Extreme Temperature Stability

PTFE maintains its structural integrity and performance characteristics across an incredibly wide temperature range. It can function effectively in environments where conventional elastomers would become brittle at low temperatures or degrade rapidly at high temperatures.

This thermal stability allows hydraulic and pneumatic systems to operate reliably in extreme conditions, from cryogenic applications to high-heat industrial processes.

Excellent Flexibility and Durability

Despite its robustness, PTFE is extremely flexible and has an excellent flex life. This makes it suitable for dynamic applications that involve constant movement, vibration, and pressure cycles.

This resilience ensures the material can conform to sealing surfaces and withstand mechanical stress without cracking or fatiguing, which is vital for components in constant motion.

How These Properties Solve Critical System Challenges

The true power of PTFE becomes clear when we see how its properties translate into solutions for real-world engineering problems in hydraulic and pneumatic systems.

Preventing Seal Failure and Contamination

The primary cause of failure in many fluid power systems is the chemical breakdown of seals. PTFE’s inertness directly prevents this, extending the life of the component and preventing costly leaks or system downtime.

Furthermore, because it is non-toxic and does not leach chemicals, PTFE ensures that the operating fluid remains uncontaminated, a critical requirement in sensitive industries like food processing and pharmaceuticals.

Ensuring System Efficiency and Reliability

In dynamic sealing, friction is the enemy of efficiency and longevity. By minimizing friction, PTFE seals reduce wear on expensive hardware like cylinder rods and valve bodies.

This low friction also leads to more precise and repeatable control over actuators, as the force required to overcome initial static friction (breakout force) is significantly lower. The result is a more efficient and reliable system.

Expanding Operational Boundaries

Engineers often select PTFE when standard materials are not an option. Its ability to withstand extreme temperatures and aggressive chemicals allows for the design of hydraulic and pneumatic systems that can operate in environments previously considered too hostile.

This capability makes PTFE indispensable in demanding sectors like aerospace, chemical processing, and heavy industry.

Understanding the Trade-offs

While highly capable, PTFE is not without its limitations. Understanding these trade-offs is key to using it effectively.

Tendency to Creep (Cold Flow)

Under sustained pressure, especially at elevated temperatures, pure PTFE can slowly deform over time. This phenomenon, known as "creep" or "cold flow," can lead to a loss of sealing pressure in some static applications.

This is often mitigated by using filled PTFE grades (compounded with materials like glass, carbon, or bronze) or by using expanded PTFE (ePTFE), which offers superior creep resistance.

Lower Abrasive Wear Resistance

While its low friction prevents adhesive wear, pure PTFE can be susceptible to abrasive wear if the system fluid contains hard particulate contaminants.

Again, filled grades of PTFE are often used to dramatically improve hardness and wear resistance in applications where abrasive particles are a concern.

Making the Right Choice for Your Application

Selecting PTFE is a decision to prioritize performance and reliability, especially when conditions are severe.

- If your primary focus is extreme chemical compatibility: PTFE is the definitive choice, preventing seal degradation and fluid contamination from aggressive media.

- If your primary focus is high-efficiency, low-friction dynamic sealing: PTFE's low coefficient of friction minimizes energy loss and wear, ensuring smooth and reliable actuator movement.

- If your primary focus is performance in wide temperature ranges: PTFE maintains its integrity and sealing capability in both cryogenic and high-heat environments where elastomers would fail.

Ultimately, choosing PTFE is an investment in system reliability, safety, and longevity, especially when operating conditions are too demanding for conventional materials.

Summary Table:

| Property | Benefit in Hydraulic/Pneumatic Systems |

|---|---|

| Chemical Inertness | Resists aggressive fluids, prevents seal degradation and contamination |

| Low Coefficient of Friction | Reduces wear, minimizes energy loss, and ensures smooth actuator movement |

| Extreme Temperature Stability | Maintains performance from cryogenic to high-heat environments |

| Flexibility & Durability | Withstands constant movement, vibration, and pressure cycles |

Elevate your hydraulic and pneumatic system reliability with KINTEK's precision PTFE components.

Our custom-fabricated PTFE seals, liners, and labware are engineered to thrive in the most demanding conditions, directly addressing the challenges of the semiconductor, medical, laboratory, and industrial sectors. We combine precision production with custom fabrication—from prototypes to high-volume orders—to deliver solutions that enhance your system's safety, efficiency, and longevity.

Contact KINTEK today to discuss your specific application requirements and discover the value of a trusted PTFE partner.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What chemical processing applications involve PTFE-machined parts? Essential Components for Corrosive & High-Purity Systems

- What fabrication services are available for PTFE? Shearing, Stamping, Laser Cutting, Molding & Machining

- What factors should be considered when choosing between Nylon and PTFE? Select the Right Material for Your Application

- What industrial benefits do PTFE-machined parts offer? Achieve Peak Performance in Demanding Applications

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications