The primary benefit of a low friction coefficient in PTFE-lined butterfly valves is the significant reduction in the operational torque required to open and close the valve. This makes actuation easier and smoother, which directly translates to less wear on the valve's sealing components over its service life.

The core insight is that low friction is not merely a convenience feature; it is a fundamental property that enhances the valve's efficiency, extends its operational lifespan, and reduces long-term maintenance costs by minimizing the two primary forces of degradation: operational stress and surface wear.

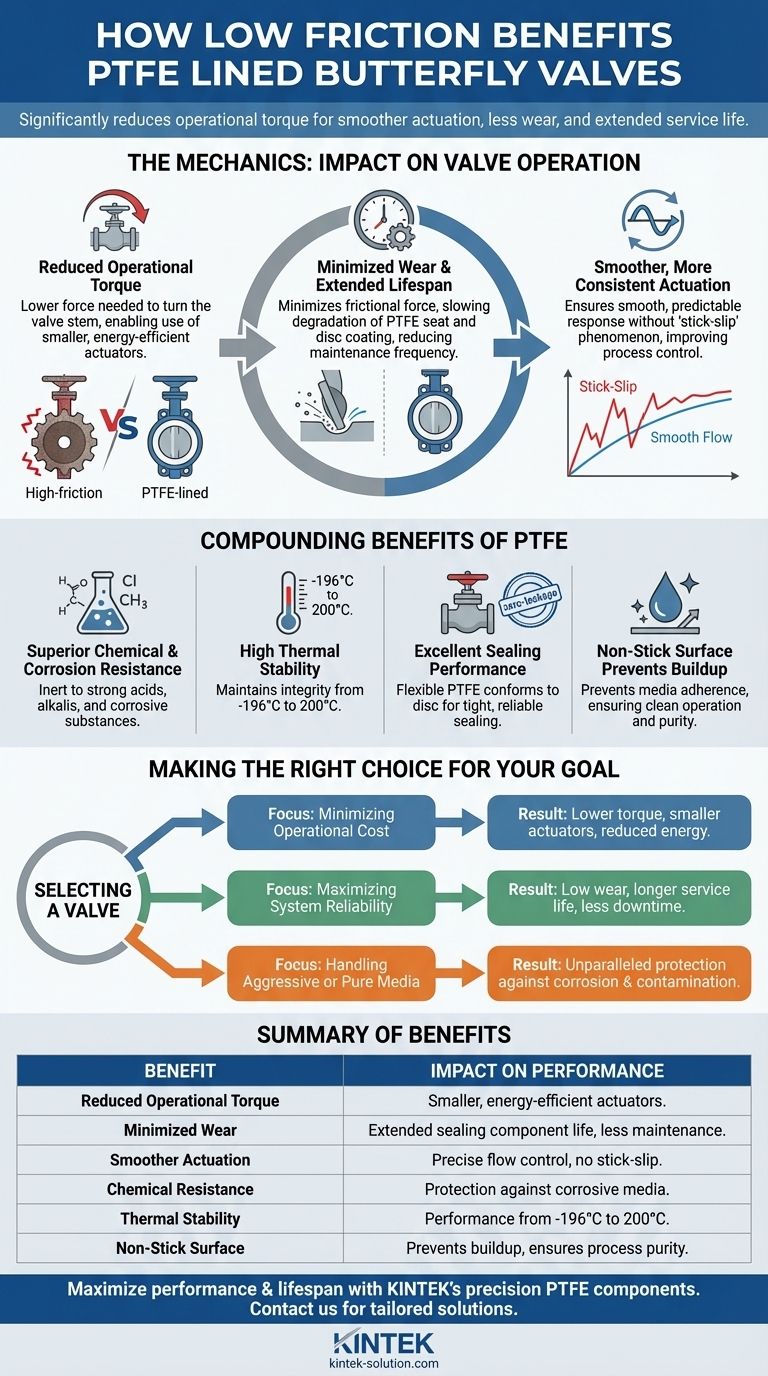

The Mechanics: How Low Friction Impacts Valve Operation

A butterfly valve operates by rotating a disc within a seat to control flow. The friction between the edge of this disc and the stationary liner (the seat) is a critical factor in the valve's performance and longevity.

Reduced Operational Torque

The force required to turn the valve stem and rotate the disc is known as operational torque.

A high coefficient of friction means the disc "grips" the seat, requiring a much larger force to break it free and move it. PTFE's extremely low friction coefficient means the disc glides against the seat with minimal resistance.

This directly results in the need for smaller, less expensive, and more energy-efficient actuators (whether electric, pneumatic, or manual).

Minimized Wear and Extended Lifespan

Friction is a direct cause of mechanical wear. Each time a high-friction valve is operated, microscopic particles of the seat and disc are worn away.

Because PTFE minimizes this frictional force, both the PTFE seat and the disc coating degrade at a much slower rate. This extends the reliable service life of the valve and reduces the frequency of costly maintenance or replacement.

Smoother, More Consistent Actuation

High friction can cause a "stick-slip" phenomenon, where the valve jerks open instead of moving smoothly. This is detrimental in applications requiring precise flow regulation.

The consistent, low-friction nature of PTFE ensures a smooth and predictable response to actuation. This improves process control and reliability, especially in automated systems.

Beyond Friction: Compounding Benefits of PTFE

While low friction is a critical starting point, its true value is realized when combined with the other inherent properties of PTFE. These characteristics work in synergy to create a highly robust and versatile valve.

Superior Chemical and Corrosion Resistance

A valve that doesn't wear out from friction is of little use if it is destroyed by the process media.

PTFE is nearly chemically inert, making it suitable for service with strong acids, alkalis, and other corrosive substances that would rapidly degrade metal or other polymer components.

High Thermal Stability

Operational environments are rarely at a constant room temperature.

PTFE maintains its structural integrity and performance characteristics across a very wide temperature range, typically from -196°C to 200°C (-320°F to 392°F). This makes it a reliable choice for both cryogenic and high-temperature applications.

Excellent Sealing Performance

The ultimate purpose of a valve in the closed position is to prevent leaks.

PTFE's flexibility allows it to conform perfectly to the disc, creating a tight seal that often achieves zero-leakage performance. The low friction ensures this sealing surface is not damaged during operation, maintaining its integrity over thousands of cycles.

Non-Stick Surface Prevents Buildup

Many process fluids contain suspended solids that can adhere to valve components, impeding operation and contaminating the media.

PTFE's famous non-stick surface prevents media from building up on the disc or seat, ensuring a clean, free-moving valve and maintaining process purity.

Making the Right Choice for Your Goal

When selecting a valve, consider how PTFE's properties align with your primary objective.

- If your primary focus is minimizing operational cost: The lower torque requirements allow for smaller, less expensive actuators and reduce long-term energy consumption.

- If your primary focus is maximizing system reliability: The combined effect of low wear, chemical resistance, and thermal stability results in a longer service life and less frequent downtime for maintenance.

- If your primary focus is handling aggressive or pure media: PTFE's chemical inertness and non-stick properties provide unparalleled protection against corrosion and contamination.

Ultimately, understanding the role of low friction is key to appreciating why PTFE-lined valves provide such durable and reliable performance across a vast range of demanding industrial applications.

Summary Table:

| Benefit | Impact on Valve Performance |

|---|---|

| Reduced Operational Torque | Enables use of smaller, more energy-efficient actuators. |

| Minimized Wear | Extends service life of sealing components, reducing maintenance. |

| Smoother Actuation | Provides precise flow control and eliminates stick-slip. |

| Chemical Resistance | Protects against corrosion from acids, alkalis, and other aggressive media. |

| Thermal Stability | Maintains performance from -196°C to 200°C. |

| Non-Stick Surface | Prevents media buildup, ensuring clean operation and process purity. |

Maximize the performance and lifespan of your fluid handling systems with KINTEK's precision PTFE components.

Our expertise in custom fabricating high-performance PTFE seals, liners, and labware ensures your equipment—from butterfly valves to complex laboratory apparatus—operates with maximum efficiency and reliability. We serve the semiconductor, medical, laboratory, and industrial sectors, delivering solutions from prototypes to high-volume orders.

Let us help you achieve superior chemical resistance, reduced maintenance, and longer service life. Contact our team today to discuss your specific requirements and receive a tailored solution.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Bottles for Diverse Industrial Applications

People Also Ask

- How does the PTFE layer enhance the functionality of elastomeric bearings? Achieve Superior Load Support and Movement

- How does Teflon coating contribute to machinery safety and efficiency? Extend Asset Life and Reduce Downtime

- What are the main disadvantages of pure PTFE? Understand Its Critical Limitations for Your Application

- What are some common fillers used in PTFE seal materials? Enhance Performance for Your Application

- What installation methods are available for PTFE slide bearings? Choose the Right Method for Your Structure

- How is Teflon used in cookware? Leveraging Non-Stick Properties for Superior Cooking

- What industries are PTFE gasket envelopes suitable for? Find the Perfect Seal for Demanding Applications

- What type of media should not be used with PTFE lined butterfly valves? Avoid These 2 Critical Failure Points