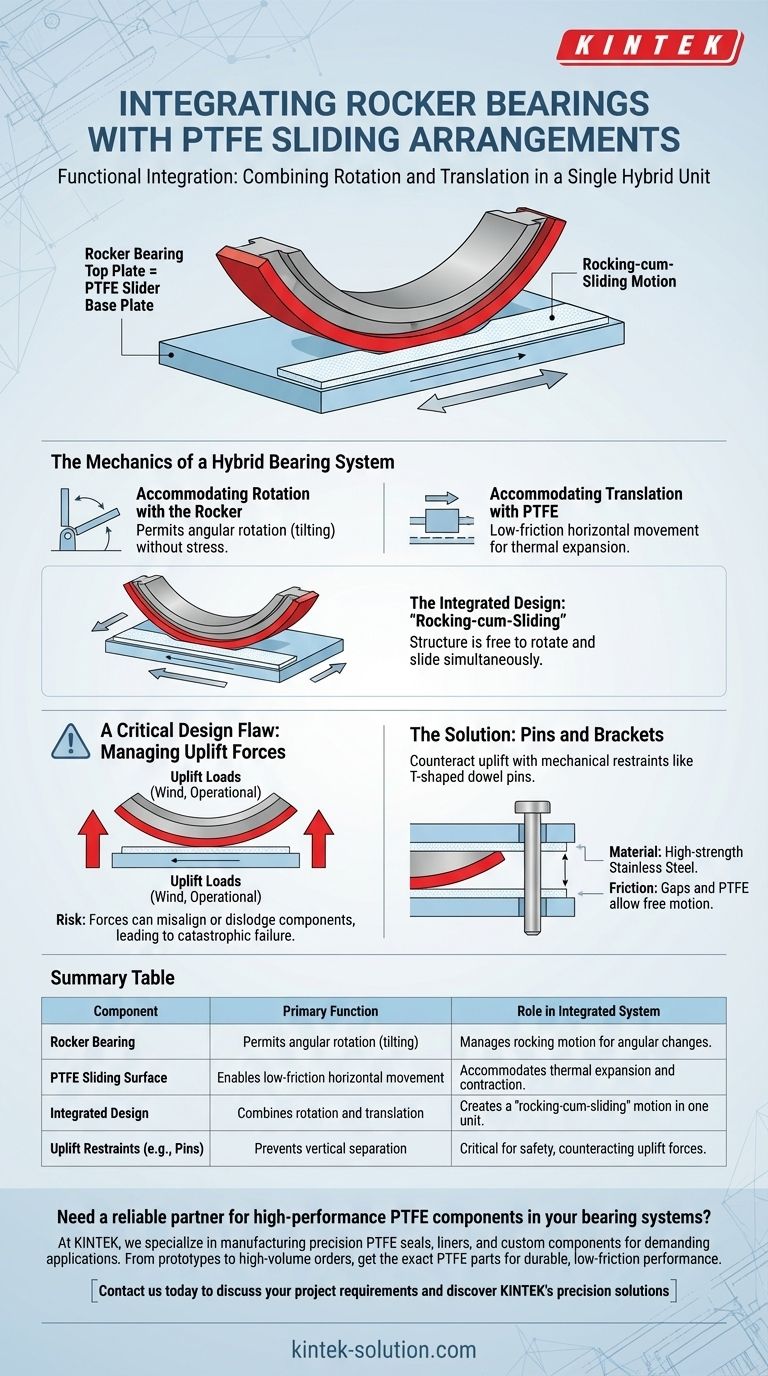

To integrate rocker bearings with PTFE sliding arrangements, the two components are combined into a single hybrid unit. In this design, the base plate that houses the PTFE sliding surface is engineered to also function as the top plate of the rocker bearing itself. This creates a sophisticated bearing capable of simultaneous rotational and translational movement.

The core principle is functional integration: by making the PTFE slider's base a direct component of the rocker bearing, you create a single device that manages both the rocking motion for angular changes and the sliding motion for horizontal expansion or contraction.

The Mechanics of a Hybrid Bearing System

Understanding this integration requires seeing how each component's primary function contributes to the combined system. The goal is to accommodate complex structural movements efficiently.

Accommodating Rotation with the Rocker

A rocker bearing is designed to permit angular rotation. It functions like a hinge, allowing a supported structure, such as a bridge deck, to tilt slightly without inducing damaging stress.

Accommodating Translation with PTFE

A PTFE (Polytetrafluoroethylene) sliding arrangement is designed for low-friction horizontal movement. This is critical for accommodating thermal expansion and contraction or other translational forces.

The Integrated Design: "Rocking-cum-Sliding"

The combination of these two systems creates what is known as a rocking-cum-sliding motion. The structure is free to rotate via the rocker mechanism while simultaneously being able to slide horizontally on the PTFE surface.

This is achieved when the top component of the rocker bearing is the same piece of metal that serves as the base plate for the PTFE pad. The two are not simply stacked; they are designed as one unified part.

A Critical Design Flaw: Managing Uplift Forces

While effective, this integrated design introduces a critical point of failure that must be addressed: uplift.

The Cause and Risk of Uplift

Forces such as heavy winds or the operational characteristics of mechanical systems can create uplift loads. These forces act to pull the bearing apart vertically.

If not properly restrained, uplift can misalign the bearing components or dislodge the sliding plate entirely, leading to catastrophic failure.

The Solution: Pins and Brackets

To counteract uplift, the design must include mechanical restraints. These commonly take the form of specialized brackets or T-shaped dowel pins.

These pins connect the upper and lower plates of the bearing, physically preventing them from separating under tensile (pulling) loads.

Material and Friction Considerations

The restraining pins must be strong enough to handle significant tensile forces. For this reason, they are often made from high-strength materials like stainless steel.

Furthermore, it is crucial that these restraints do not impede the bearing's intended movement. Gaps between the pins and their corresponding slots must be sufficient for free motion, and PTFE may even be used between these surfaces to minimize friction.

How to Apply This to Your Design

Choosing and specifying this type of bearing requires balancing its dual-motion capability with its inherent vulnerabilities.

- If your primary focus is accommodating complex movement: This hybrid design is an excellent solution for structures that experience both angular deflection and thermal expansion.

- If your primary focus is structural safety and longevity: You must explicitly design for potential uplift forces by specifying robust restraint systems like stainless steel dowel pins.

Ultimately, a correctly specified integrated bearing provides a highly effective solution by managing multiple degrees of freedom within a single component.

Summary Table:

| Component | Primary Function | Role in Integrated System |

|---|---|---|

| Rocker Bearing | Permits angular rotation (tilting) | Manages rocking motion for angular changes. |

| PTFE Sliding Surface | Enables low-friction horizontal movement | Accommodates thermal expansion and contraction. |

| Integrated Design | Combines rotation and translation | Creates a "rocking-cum-sliding" motion in one unit. |

| Uplift Restraints (e.g., Pins) | Prevents vertical separation | Critical for safety, counteracting wind or operational uplift forces. |

Need a reliable partner for high-performance PTFE components in your bearing systems?

At KINTEK, we specialize in manufacturing precision PTFE seals, liners, and custom components essential for demanding applications in the semiconductor, medical, laboratory, and industrial sectors. Our expertise in custom fabrication—from prototypes to high-volume orders—ensures you get the exact PTFE parts you need for durable, low-friction performance in integrated bearing designs.

Contact us today to discuss your project requirements and discover how KINTEK's precision PTFE solutions can enhance the safety and efficiency of your designs.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications