At their core, PTFE rotary seals are high-performance components defined by their exceptional resistance to extreme conditions. They function reliably across a vast temperature range, from -200°C to +260°C, and are virtually inert to almost all industrial chemicals, oils, and solvents. This combination of thermal stability and chemical resistance makes them the superior choice for applications where traditional elastomeric seals would quickly fail.

PTFE rotary seals are not a universal replacement for standard seals, but rather a specialized solution for extreme operating conditions. Their true power lies in their ability to handle high temperatures, aggressive chemicals, and high-speed applications, but this performance often relies on specific filler materials that overcome the inherent softness of pure PTFE.

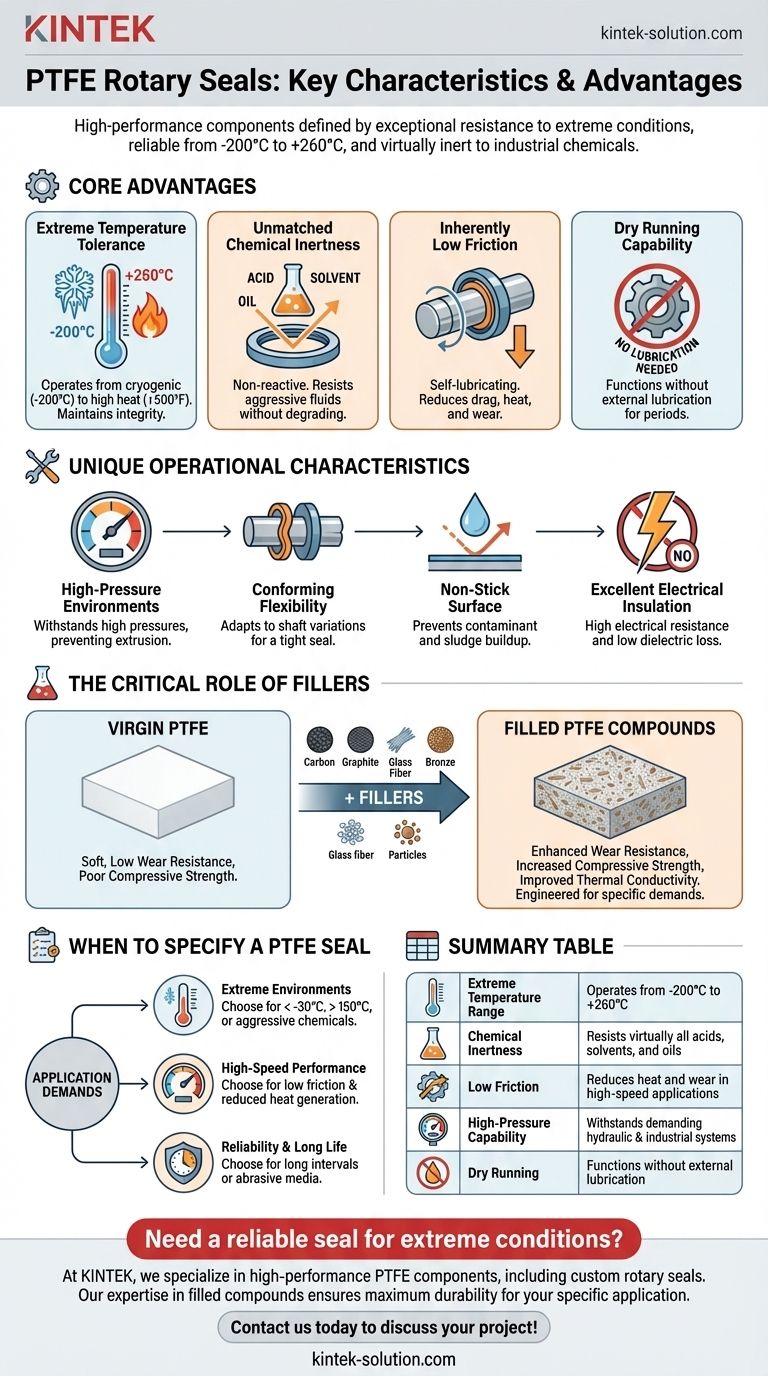

The Core Advantages of PTFE Seals

The unique molecular structure of Polytetrafluoroethylene (PTFE) gives these seals a set of powerful baseline characteristics that set them apart from materials like rubber or nitrile.

Extreme Temperature Tolerance

PTFE seals maintain their integrity and sealing capability across an exceptionally wide thermal range. They can operate effectively in cryogenic conditions as low as -200°C (-328°F) and in high-heat environments up to +260°C (+500°F).

Unmatched Chemical Inertness

A defining feature of PTFE is its non-reactive nature. These seals can be used with the most aggressive acids, solvents, and industrial fluids without swelling, degrading, or failing. This makes them indispensable in chemical processing and pharmaceutical applications.

Inherently Low Friction

PTFE has one of the lowest coefficients of friction of any solid material. This self-lubricating property reduces drag and heat generation in high-speed rotary applications, which in turn minimizes shaft wear and extends the service life of both the seal and the equipment.

Dry Running Capability

The low-friction nature of PTFE allows these seals to run dry (without external lubrication) for periods without catastrophic failure. This is a significant advantage over elastomeric seals, which would be quickly destroyed in such conditions.

Unique Operational Characteristics

Beyond the core material properties, PTFE seals offer distinct operational benefits that solve specific engineering challenges.

High-Pressure Environments

PTFE seals are engineered to withstand high pressures that would cause standard elastomeric seals to extrude or fail. Their durability makes them a reliable choice for hydraulic systems and other demanding operations.

Conforming Flexibility

Despite their strength, PTFE oil seals are flexible enough to conform to variations in shaft geometry. This allows them to maintain a tight, reliable seal even on shafts that may be slightly irregular or worn.

Non-Stick Surface

The non-stick properties of PTFE prevent contaminants, sludge, or other media from building up on the seal lip. This ensures consistent performance and reduces the risk of premature wear.

Excellent Electrical Insulation

PTFE is an exceptional electrical insulator with a high volume resistance and low dielectric loss. Its insulating properties are not affected by frequency or environmental conditions, making it useful in specialized electro-mechanical equipment.

Understanding the Trade-offs: Virgin PTFE vs. Filled Compounds

It is critical to understand that the remarkable durability often associated with PTFE seals comes from enhancement, not from the base material alone.

The Weaknesses of Virgin PTFE

Pure, unfilled PTFE is a relatively soft material. It has limited wear resistance, low stiffness, and poor compressive strength. When used against hard surfaces in demanding applications, virgin PTFE can wear quickly.

How Fillers Create High-Performance Seals

To overcome these limitations, PTFE is blended with filler materials like carbon, graphite, glass fiber, or bronze. These fillers dramatically improve key properties:

- Wear Resistance: Fillers drastically increase durability and lifespan.

- Compressive Strength: They reduce deformation under load.

- Thermal Conductivity: They help dissipate heat away from the sealing lip.

The specific blend of fillers is engineered to match the demands of the application, such as high speed, high pressure, or abrasive media.

When to Specify a PTFE Rotary Seal

Choosing the right seal requires matching the material to the operational demands. A PTFE seal is the correct technical choice when your primary concerns align with its core strengths.

- If your primary focus is extreme environments: Specify a PTFE seal for any application involving temperatures below -30°C or above 150°C, or when contact with aggressive chemicals would degrade a standard rubber seal.

- If your primary focus is high-speed performance: A PTFE seal is the superior choice for high-speed shafts where its low-friction properties will reduce heat generation, minimize wear, and lower energy consumption.

- If your primary focus is reliability and long life: Use a filled PTFE seal in applications requiring long maintenance intervals, low friction, or the ability to withstand abrasive media without premature failure.

By understanding both its inherent strengths and the critical role of material composition, you can confidently specify a PTFE seal for your most demanding applications.

Summary Table:

| Characteristic | Benefit |

|---|---|

| Extreme Temperature Range | Operates from -200°C to +260°C |

| Chemical Inertness | Resists virtually all acids, solvents, and oils |

| Low Friction | Reduces heat and wear in high-speed applications |

| High-Pressure Capability | Withstands demanding hydraulic and industrial systems |

| Dry Running | Functions without external lubrication |

Need a reliable seal for extreme conditions?

At KINTEK, we specialize in manufacturing high-performance PTFE components, including custom rotary seals. Our expertise in filled PTFE compounds ensures your seals deliver maximum wear resistance, thermal stability, and longevity for your specific application—whether in semiconductor, medical, laboratory, or industrial settings.

We offer custom fabrication from prototypes to high-volume orders, prioritizing precision to meet your exact requirements.

Contact us today to discuss your project and get a quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications