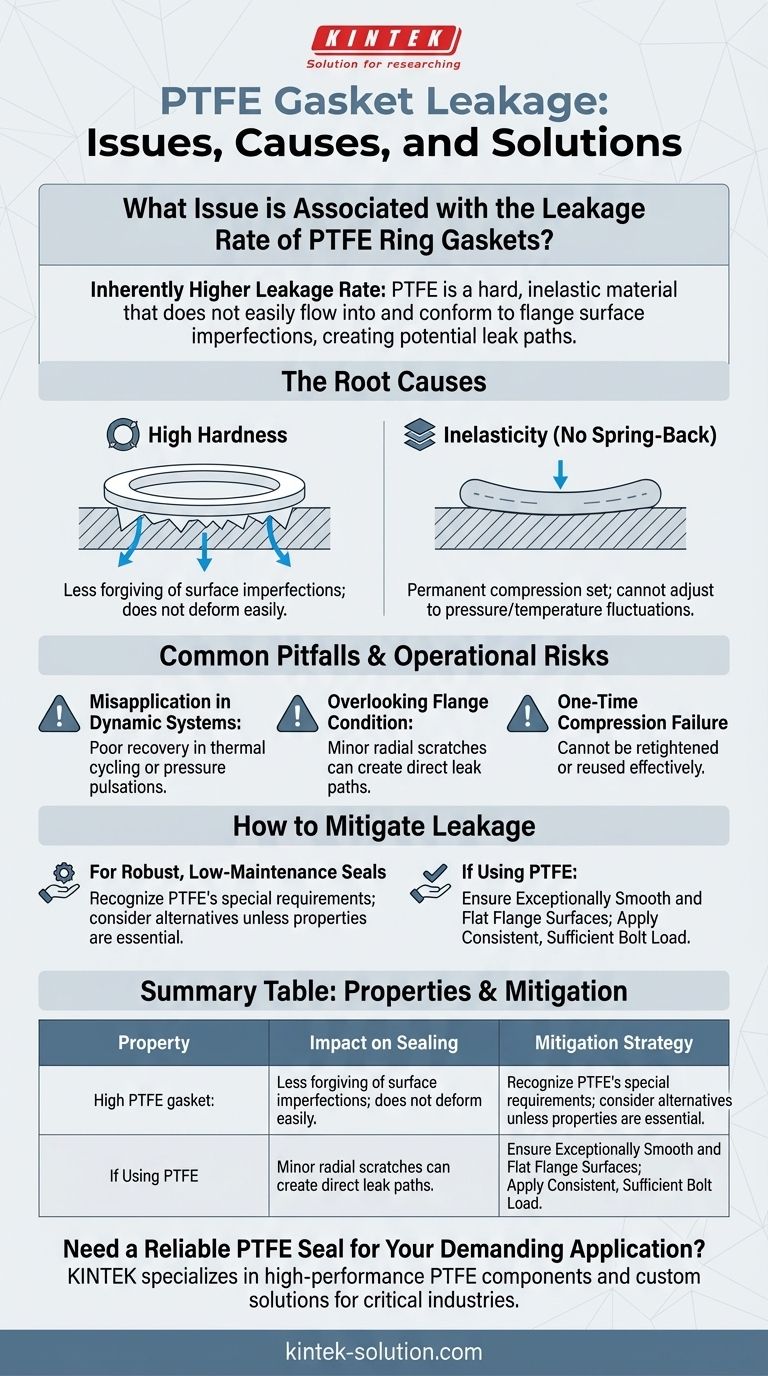

The primary issue associated with PTFE ring gaskets is their inherently higher leakage rate when compared to other gasket materials. This tendency to leak is not a defect but a direct result of PTFE's fundamental physical properties, specifically its high hardness and lack of elasticity, which necessitate special considerations to achieve a reliable seal.

The core problem is that PTFE is a hard, inelastic material. Unlike softer, more elastic gaskets, it does not easily flow into and conform to the microscopic imperfections of a flange surface, creating a greater potential for leak paths.

The Root Causes of PTFE Gasket Leakage

To properly manage PTFE gaskets, it is essential to understand the specific material characteristics that contribute to their higher leak potential. These properties are distinct from more common elastomer or composite gasket materials.

The Problem of High Hardness

PTFE is a relatively hard plastic. This hardness prevents it from deforming and seating as easily as a softer material under the compressive load from flange bolts.

A softer gasket will readily fill minor scratches, voids, and waviness on a flange face. The hardness of PTFE means it is less forgiving of these surface imperfections, which can remain as potential leak paths after installation.

The Impact of Inelasticity

Perhaps the most significant disadvantage of PTFE is that it is inelastic. This means that once it is compressed, it does not return to its original shape.

This lack of "spring-back" or memory means the gasket cannot dynamically adjust to changes in pressure, temperature fluctuations, or flange movement. If the compressive load on the gasket relaxes for any reason, the seal can be compromised.

The Need for Superior Surface Finish

Because of PTFE's hardness and inability to flow into surface irregularities, achieving a reliable seal is highly dependent on the quality of the mating flange surfaces.

The references to requiring post-process surface finish improvements highlight this fact. To use PTFE gaskets effectively, flange surfaces must be exceptionally smooth and flat to minimize the gaps the gasket must seal.

Common Pitfalls and Operational Risks

The unique properties of PTFE gaskets introduce specific risks that must be managed during design and installation. Ignoring them is a common source of sealing failure.

Misapplication in Dynamic Systems

PTFE's inelasticity makes it a poor choice for applications with significant thermal cycling or pressure pulsations. These conditions can cause the flange load to vary, and the gasket lacks the ability to recover and maintain a tight seal.

Overlooking Flange Condition

Teams that are accustomed to more forgiving gasket materials may not inspect flange surfaces with sufficient rigor. With PTFE, even minor radial scratches across the flange face can create a direct leak path that the hard gasket cannot seal.

One-Time Compression Failure

There is no opportunity to "retighten" a PTFE gasket and expect it to perform as new. Since it is inelastic, it takes a permanent compression set upon its initial installation. Once used, it cannot be effectively reused or adjusted.

How to Mitigate Leakage with PTFE

If PTFE is required for its chemical resistance or other properties, you must adopt a strategy that directly compensates for its physical limitations.

- If your priority is a robust, low-maintenance seal: Recognize that PTFE requires more careful engineering and installation than other options and may not be the most suitable choice unless its other properties are essential.

- If you must use a PTFE gasket: Your primary focus must be on ensuring the flange surfaces are exceptionally smooth and flat, and that a consistent, sufficient bolt load is applied during a single installation event.

Making an informed decision requires weighing PTFE's excellent chemical inertness against the stringent mechanical requirements for achieving a reliable seal.

Summary Table:

| Property | Impact on Sealing | Mitigation Strategy |

|---|---|---|

| High Hardness | Less forgiving of surface imperfections, creating leak paths. | Requires exceptionally smooth and flat flange surfaces. |

| Inelasticity (No Spring-Back) | Cannot adjust to pressure/temperature changes; permanent compression set. | Apply consistent, sufficient bolt load; avoid reuse and dynamic systems. |

| Chemical Inertness | Excellent resistance to aggressive chemicals. | Ideal for corrosive applications where this property is essential. |

Need a reliable PTFE seal for your demanding application?

PTFE's unique properties make sealing complex, but the right design and manufacturing precision make all the difference. At KINTEK, we specialize in manufacturing high-performance PTFE components—including seals, liners, and custom labware—for the semiconductor, medical, laboratory, and industrial sectors.

We understand the critical balance between chemical resistance and mechanical performance. Our expertise in custom fabrication, from prototypes to high-volume orders, ensures your PTFE gaskets are engineered for success, mitigating leakage risks from the start.

Let us help you achieve a robust, leak-free seal. Contact our experts today to discuss your specific requirements and explore a precision solution.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Customizable PTFE Rods for Advanced Industrial Applications

People Also Ask

- Why is PTFE considered a significant discovery? A Material That Revolutionized Industry

- Why is dimensional stability a concern when machining PTFE? Ensure Accurate, Stable PTFE Components

- How is PTFE used in industrial processes? Maximize Safety and Efficiency

- How does PTFE compare to other low-friction plastics like UHMW-PE and Nylon? A Guide to Material Selection

- When and by whom was PTFE discovered? A Tale of Accidental Innovation