To choose the right gasket material, you must systematically evaluate the operating environment, the specific application requirements, and the total cost-effectiveness. The key factors are the system's temperature, pressure, and chemical compatibility, as these conditions most directly dictate whether a seal will hold or fail over time.

The goal is not to find a single "best" material, but to select the material that creates the most stable and reliable seal within the unique conditions of your specific system. A gasket's success is defined entirely by its environment.

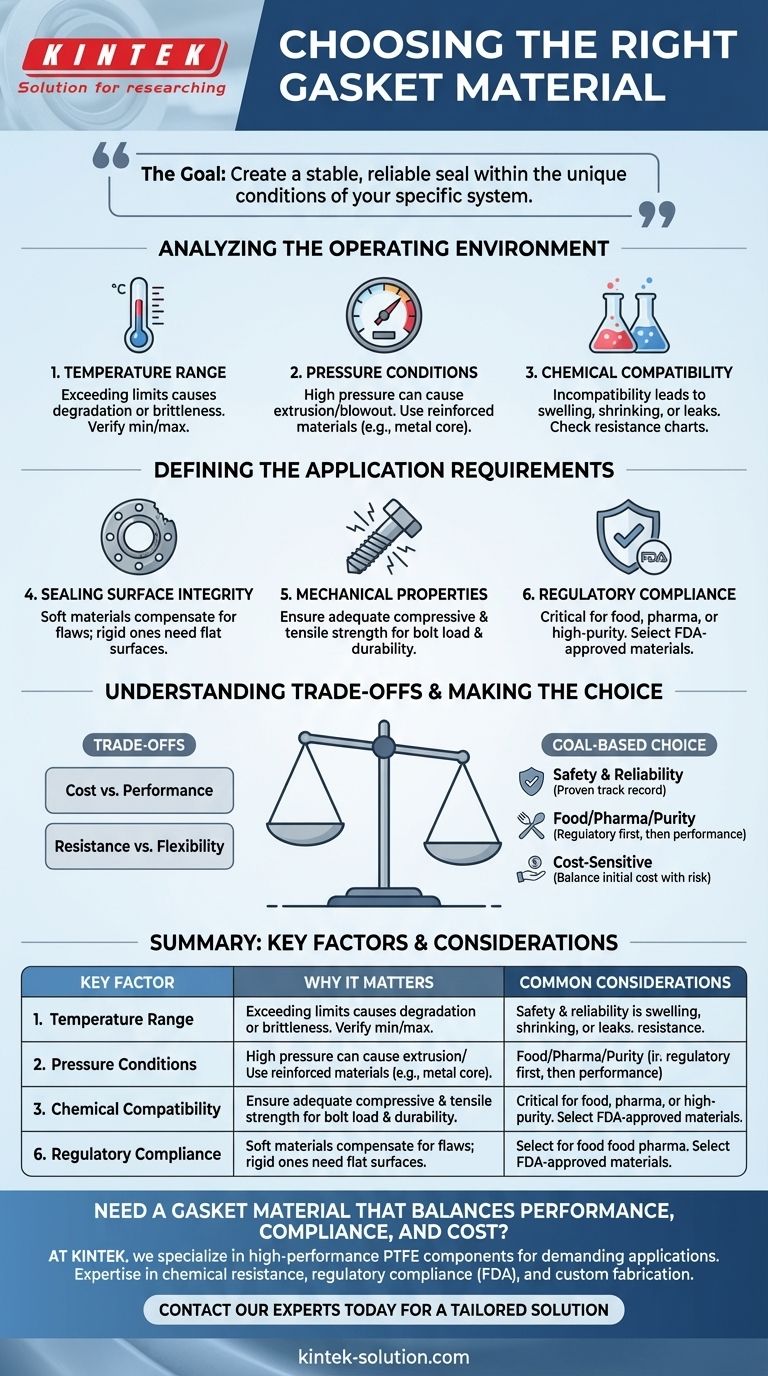

Analyzing the Operating Environment

The physical and chemical conditions surrounding the gasket are the most critical factors in your decision. A material perfectly suited for one environment can fail catastrophically in another.

Factor 1: Temperature Range

Every material has a defined operating temperature range. Exceeding this range, even for short periods, can cause permanent damage and seal failure.

Extreme heat can cause a material to soften, degrade, or lose its compressive strength, while extreme cold can make it brittle and prone to cracking. Always verify the material's suitability for both the minimum and maximum temperatures it will experience.

Factor 2: Pressure Conditions

The internal pressure of the system exerts force on the gasket, trying to push it out of place. The gasket material must be strong enough to resist this force without being crushed or extruded.

For high-pressure applications, you may need a stronger or reinforced material, such as those that incorporate a metal core, to prevent blowout.

Factor 3: Chemical Compatibility

The gasket must remain inert when exposed to the fluids or gases it is sealing. Incompatibility can lead to the material swelling, shrinking, or dissolving, which inevitably results in a leak.

Always cross-reference the gasket material's chemical resistance chart with every chemical it will contact in your application.

Defining the Application Requirements

Beyond the immediate environment, the mechanical and regulatory demands of the application will further narrow your material choices.

Factor 4: Sealing Surface Integrity

No gasket can perform optimally on a damaged or uneven surface. The material you choose must be able to conform to the flange surfaces to create a complete seal.

Softer, more flexible materials can often compensate for minor surface imperfections, whereas harder, more rigid materials require nearly perfect, flat surfaces to seal effectively.

Factor 5: Mechanical Properties

A gasket must withstand the compressive load from bolts (the bolt load) required to create a seal, without being crushed. This property, known as compressive strength, is essential for maintaining seal integrity over time.

The material must also have sufficient tensile strength to resist being torn or damaged during installation and operation.

Factor 6: Regulatory Compliance

Many industries have strict standards for materials used in their processes. This is especially true for food, beverage, and pharmaceutical applications.

If your application involves human consumption or high-purity processes, you must select a material that meets specific standards, such as being FDA-approved.

Understanding the Trade-offs

Selecting a gasket material is an exercise in balancing competing properties. Understanding these trade-offs is crucial for making an informed, cost-effective decision.

Cost vs. Performance

The cheapest material is rarely the most cost-effective. An inexpensive gasket that fails prematurely can lead to costly downtime, product loss, or safety incidents that far outweigh the initial savings.

Always evaluate the total cost of ownership, which includes the risk and cost of failure, not just the purchase price.

Chemical Resistance vs. Flexibility

Often, the most chemically resistant materials, like PTFE, are more rigid than other elastomers. While they offer superior protection against corrosive media, their rigidity may require better flange surfaces to achieve a proper seal.

In contrast, a more flexible rubber material might seal more easily on an imperfect surface but have a more limited range of chemical compatibility.

Making the Right Choice for Your Goal

Your final decision should be guided by your primary objective for the sealed joint.

- If your primary focus is maximum safety and reliability: Prioritize materials with a proven track record in your specific temperature, pressure, and chemical environment, even at a higher cost.

- If your primary focus is a food, pharma, or high-purity application: Your first filter must be regulatory compliance (e.g., FDA, USP Class VI), then select from that approved list based on performance.

- If your primary focus is a cost-sensitive, non-critical system: Balance the initial material cost with the expected service life and the low consequence of a potential leak.

Choosing the right gasket is about ensuring the long-term integrity and safety of your entire system.

Summary Table:

| Key Factor | Why It Matters | Common Considerations |

|---|---|---|

| Temperature Range | Exceeding limits causes degradation or brittleness. | Verify min/max operating temperatures for the material. |

| Pressure Conditions | High pressure can cause extrusion or blowout. | Use reinforced materials (e.g., metal core) for high-pressure systems. |

| Chemical Compatibility | Incompatibility leads to swelling, shrinking, or leaks. | Check chemical resistance charts for all media in the system. |

| Sealing Surface Integrity | Imperfect surfaces require conformable materials. | Softer materials compensate for flaws; rigid ones need flat flanges. |

| Mechanical Properties | Bolt load and tensile strength affect seal durability. | Ensure adequate compressive and tensile strength for the application. |

| Regulatory Compliance | Critical for food, pharma, or high-purity applications. | Select FDA-approved or industry-compliant materials as required. |

Need a Gasket Material That Balances Performance, Compliance, and Cost?

At KINTEK, we specialize in manufacturing high-performance PTFE components—including seals, gaskets, liners, and labware—for demanding applications in the semiconductor, medical, laboratory, and industrial sectors. Our expertise ensures your gasket material is precisely suited to your operating environment, whether you require superior chemical resistance, regulatory compliance (like FDA standards), or custom fabrication from prototypes to high-volume orders.

Let us help you achieve a reliable, long-lasting seal. Contact our experts today for a tailored solution that prioritizes your system's integrity and safety.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What are the key benefits of PTFE in custom fabrication? Unlock Performance in Extreme Conditions

- What are some common applications of machined PTFE? Leverage its Unique Properties for Demanding Applications

- What are the base characteristics of PTFE? Unlocking Extreme Performance in Friction, Temperature, and Chemical Resistance

- What is PTFE commonly known as and what are its unique properties? Unlock Unmatched Chemical & Thermal Resistance