Beyond the kitchen, Teflon’s unique properties make it an indispensable material in fields ranging from aerospace and medicine to pyrotechnics and consumer electronics. While famous for its non-stick coating on cookware, its true value lies in a rare combination of chemical inertness, temperature resistance, and an extremely low coefficient of friction. These characteristics allow it to solve critical engineering challenges where other materials would fail.

The widespread use of Teflon has less to do with any single feature and more to do with its powerful combination of three core properties: it is nearly impervious to chemical attack, it remains stable at extreme temperatures, and it is one of the most slippery substances known to science.

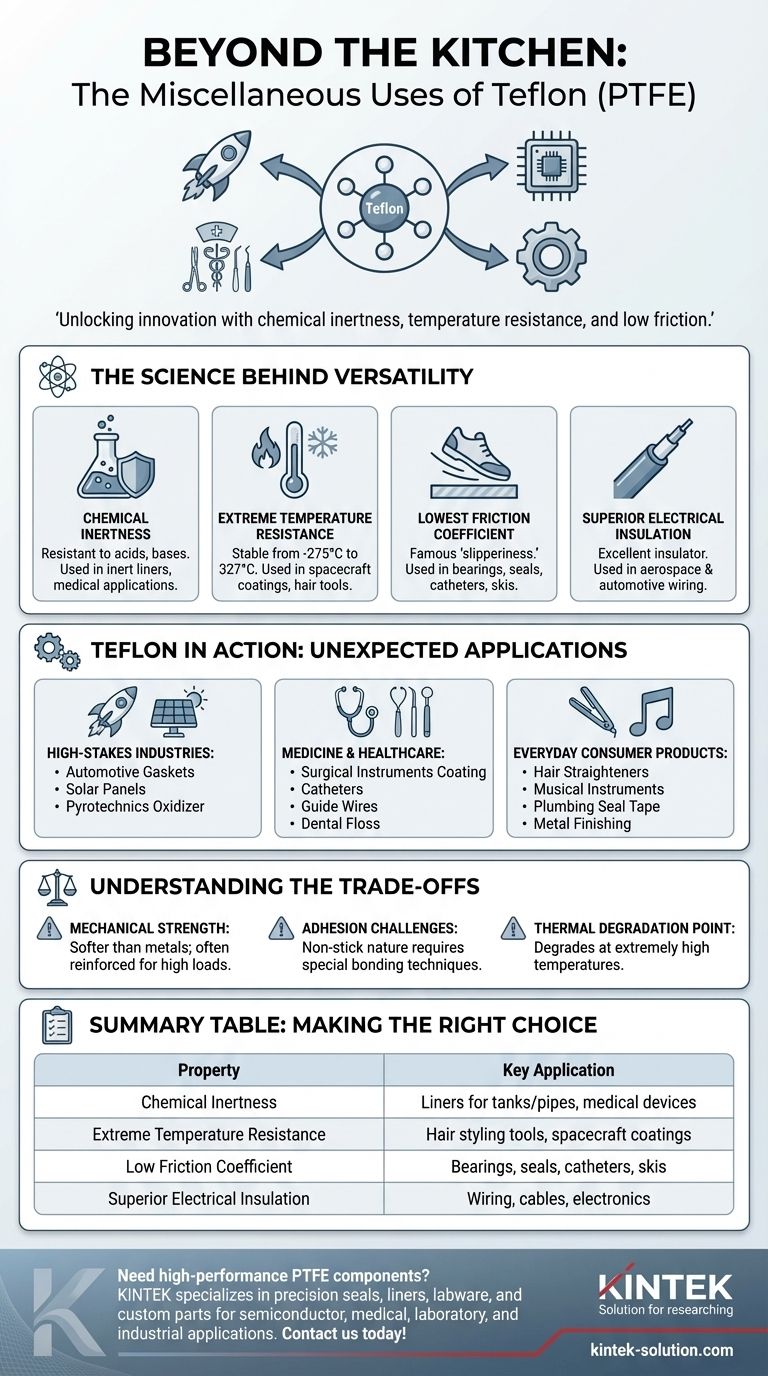

The Science Behind Teflon's Versatility

To understand Teflon's diverse applications, one must first understand its fundamental material properties. These traits are what engineers and designers leverage to solve specific problems.

Unmatched Chemical Inertness

Teflon (PTFE) is resistant to a vast range of chemicals, acids, and bases. This non-reactive nature makes it invaluable for handling or containing corrosive substances.

This property is why it's used for chemically inert liners in storage tanks and pipes, ensuring the integrity of both the container and the substance within it. It's also critical for medical applications where materials must not react with bodily fluids.

Extreme Temperature Resistance

Teflon performs reliably across an exceptional temperature spectrum, handling continuous service temperatures up to 327°C (620°F) and remaining durable at cryogenic lows of -275°C (-463°F).

This thermal stability makes it suitable for high-heat applications like hair styling tools and kitchen appliances, as well as for components in spacecraft coatings that must endure the extreme temperature swings of space.

The Lowest Friction Coefficient

Teflon has one of the lowest coefficients of friction of any solid material, giving it its famous "slipperiness." This property is essential for reducing wear and energy loss in mechanical systems.

It is the key reason Teflon is used in self-lubricating bearings, seals, and gaskets. This same low-friction quality is applied to everything from coatings on skis for better glide to medical catheters for easier insertion.

Superior Electrical Insulation

Teflon is an excellent electrical insulator, meaning it does not conduct electricity. This makes it a perfect material for protecting wires and electronic components.

You will find it used extensively as a coating for electrical wires and cables, especially in high-performance automotive and aerospace applications where reliability is paramount.

Teflon in Action: Unexpected Applications

By combining these core properties, Teflon has found its way into a surprising number of specialized and everyday products.

In High-Stakes Industries

In sectors where failure is not an option, Teflon provides reliability. It is used in automotive gaskets to create durable seals, in solar panels for protective layers, and even as an oxidizer in pyrotechnics for certain fireworks formulations.

In Medicine and Healthcare

Because it is chemically inert and has low friction, Teflon is highly biocompatible. It is used to coat surgical instruments and in sterilization equipment to prevent sticking and contamination.

It is also found in medical products like catheters and guide wires, as well as in dental applications like high-performance dental floss and certain types of fillings.

In Everyday Consumer Products

Beyond the frying pan, Teflon improves many common items. It coats the plates of hair straighteners and curling irons to prevent snagging while resisting high heat.

It's also used to coat musical instruments for protection and durability, in plumbing seal tape for its easy application and removal, and in paint and metal finishing to create durable, low-friction surfaces.

Understanding the Trade-offs

No material is perfect for every situation, and Teflon is no exception. Its unique advantages come with inherent limitations that are important to recognize.

Mechanical Strength

While durable, Teflon is a relatively soft polymer compared to metals. In high-load mechanical applications like bearings, it may be combined with other materials like glass or bronze to improve its strength and resistance to deformation.

Adhesion Challenges

Teflon's non-stick nature is its greatest asset, but it also makes it difficult to bond to other surfaces. Attaching a Teflon coating or liner often requires special surface preparation techniques, such as chemical etching, to ensure a lasting bond.

Thermal Degradation Point

While Teflon has excellent heat resistance for most applications, it can begin to degrade at extremely high temperatures (well above typical cooking temperatures). In specialized industrial settings, this thermal limit must be respected to prevent the material from breaking down.

Making the Right Choice for Your Goal

Understanding Teflon's core strengths allows you to see why it is chosen for such a diverse array of tasks. Its selection is almost always a direct solution to a problem involving friction, chemicals, or temperature.

- If your primary focus is reducing friction: Teflon is a definitive choice for creating non-stick surfaces, self-lubricating mechanical parts, and low-resistance coatings.

- If your primary focus is chemical resistance: It is an ideal liner for pipes, vessels, and containers that will be exposed to corrosive or high-purity substances.

- If your primary focus is high-performance insulation: Its combination of thermal stability and excellent dielectric properties makes it a top-tier material for critical wiring and electronics.

Ultimately, Teflon's journey from the lab to countless industries is a masterclass in how a material's fundamental properties can unlock a world of innovation.

Summary Table:

| Property | Key Application |

|---|---|

| Chemical Inertness | Liners for tanks/pipes, medical devices |

| Extreme Temperature Resistance | Hair styling tools, spacecraft coatings |

| Low Friction Coefficient | Bearings, seals, catheters, skis |

| Superior Electrical Insulation | Wiring, cables, electronics |

Need high-performance PTFE components for your project? KINTEK specializes in manufacturing precision PTFE seals, liners, labware, and custom components for semiconductor, medical, laboratory, and industrial applications. Whether you need prototypes or high-volume orders, we deliver durable, chemically inert solutions tailored to your needs. Contact us today to discuss how our PTFE expertise can enhance your product’s reliability and performance!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs