In short, PTFE balls are highly functional in applications that demand extreme chemical resistance and self-lubrication, but not high mechanical strength. They are primarily used in components like ball valves, chemical pumps, and light-load bearings that operate in corrosive environments or where external lubricants are impractical.

The decision to use a PTFE ball is almost never about strength; it's a strategic choice for its unparalleled chemical inertness and exceptionally low-friction surface, making it the ideal material for hostile chemical environments and self-lubricating systems.

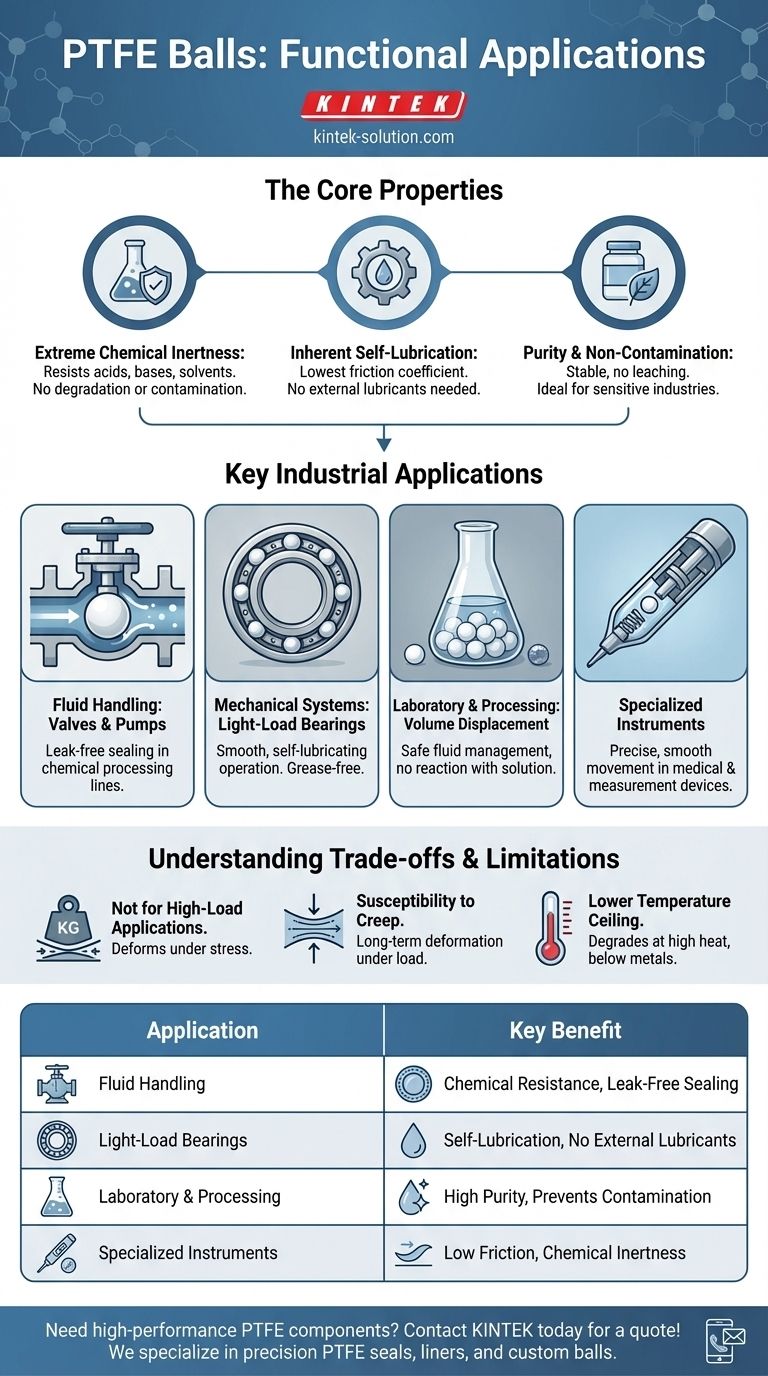

The Core Properties Driving PTFE Ball Selection

To understand where PTFE balls excel, we must first examine the material's unique characteristics. Its value comes from a specific combination of properties that are difficult to find in other materials.

Extreme Chemical Inertness

PTFE is renowned for its resistance to nearly all industrial chemicals, including aggressive acids, bases, solvents, and salts. This makes it a default choice for components that are in direct contact with corrosive fluids. It maintains its structural integrity without degrading, ensuring reliability and preventing process contamination.

Inherent Self-Lubrication

PTFE has one of the lowest coefficients of friction of any solid material. This property means it requires no external lubricant, reducing system complexity and eliminating a potential source of contamination. This "slipperiness" is ideal for moving parts in clean environments.

Purity and Non-Contamination

Because it is so inert and stable, PTFE does not leach chemicals or contaminants into the fluids it touches. This purity is a non-negotiable requirement in industries like pharmaceuticals, food and beverage, and electronics manufacturing.

Key Industrial Applications in Detail

These core properties make PTFE balls the optimal solution for several specific industrial and scientific applications.

Fluid Handling: Valves and Pumps

This is the most common use case. PTFE balls are used as check balls in pumps and as the central sealing component in ball valves. Their ability to form a tight seal while resisting chemical attack ensures long-term, leak-free operation in chemical processing lines.

Mechanical Systems: Light-Load Bearings

In ball bearings designed for light loads, PTFE balls provide smooth, self-lubricating operation. They are particularly useful where grease or oil is undesirable, such as in food processing equipment or sensitive measurement instruments.

Laboratory and Processing: Volume Displacement

In chemical baths and other processing tanks, solid PTFE balls are often used for volume displacement. They can reduce the required volume of expensive or hazardous chemicals in a tank without reacting with the solution, providing a safe and cost-effective method of fluid management.

Specialized Instruments

PTFE balls are also found in various medical and measurement devices. Their combination of chemical inertness and low friction is valuable for components that must move smoothly and not react with biological samples or sensitive reagents.

Understanding the Trade-offs and Limitations

While highly functional, PTFE is not a universal solution. An expert technical decision requires understanding its limitations.

Not for High-Load Applications

PTFE is a relatively soft material compared to steel or ceramic. It has low compressive strength and should not be used in bearings or other applications that are subject to high mechanical stress or heavy loads, as it can deform.

Susceptibility to Creep

Under a sustained load, even a light one, PTFE can slowly deform over time—a phenomenon known as "creep." This must be accounted for in any design that requires long-term dimensional stability under pressure.

Lower Temperature Ceiling Than Metals

While PTFE has good heat resistance for a polymer, its operational temperature range is significantly lower than that of metals or ceramics. Its properties begin to degrade at high temperatures, limiting its use in high-heat applications.

Making the Right Choice for Your Goal

Ultimately, the choice to use PTFE balls depends entirely on your primary engineering goal.

- If your primary focus is chemical compatibility: PTFE is an industry-leading choice for valves, pumps, and seals that will be exposed to corrosive fluids.

- If your primary focus is self-lubrication: PTFE is ideal for light-load bearings and moving parts where external lubricants would cause contamination.

- If your primary focus is fluid purity: PTFE is one of the best materials for applications in the food, pharmaceutical, or electronics industries where preventing contamination is critical.

Choosing the right material is about matching its distinct properties to the specific demands of your application.

Summary Table:

| Application | Key Benefit of PTFE Balls |

|---|---|

| Fluid Handling (Valves, Pumps) | Extreme chemical resistance, leak-free sealing |

| Light-Load Bearings | Self-lubrication, no external lubricants needed |

| Laboratory & Processing | High purity, prevents contamination |

| Specialized Instruments | Low friction, chemical inertness for sensitive environments |

Need high-performance PTFE components for your application?

At KINTEK, we specialize in manufacturing precision PTFE components—including seals, liners, labware, and custom balls—for the semiconductor, medical, laboratory, and industrial sectors. Whether you need prototypes or high-volume orders, our expertise ensures your components meet the highest standards for chemical resistance and purity.

Contact us today to discuss your specific requirements and get a quote!

Visual Guide

Related Products

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE and Nitrile Diaphragm Pump Components for Demanding Applications

- Customizable PTFE Rods for Advanced Industrial Applications

People Also Ask

- What size range do PTFE balls come in? A Guide from 3mm to 100mm

- What materials are used for PTFE balls? A Guide to Virgin PTFE vs. Filled Composites

- What temperature range can PTFE balls withstand? Unlock Extreme Thermal Stability from -200°C to 260°C

- What makes PTFE balls ideal for chemical applications? Unmatched Inertness for Demanding Environments

- What industries commonly use PTFE balls? Essential for Chemical, Pharma, and Food Processing