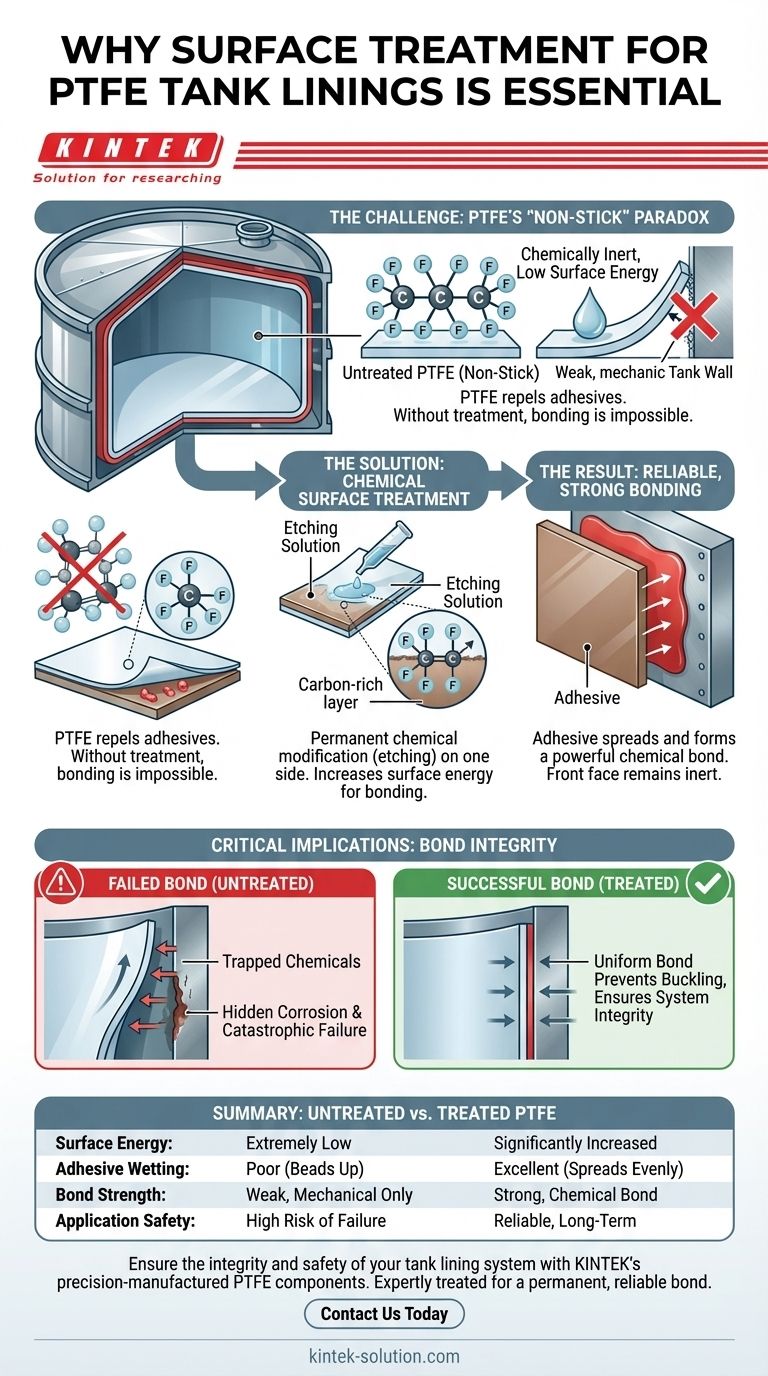

In short, surface treatment is necessary because Polytetrafluoroethylene (PTFE) is inherently a "non-stick" material with extremely low surface energy. Without a specialized treatment process, no adhesive can form a strong, reliable bond with the PTFE sheet, making it impossible to securely attach it as a protective lining inside a metal tank.

The core challenge is a paradox: PTFE's exceptional chemical inertness, which makes it an ideal tank liner, also makes it repel the very adhesives needed to install it. Surface treatment solves this by chemically altering one side of the sheet, creating a bondable surface without compromising the protective front face.

The Fundamental Challenge: PTFE's Natural Inertness

PTFE's unique properties make it both the perfect solution for chemical containment and a significant engineering challenge for installation. Understanding this dual nature is key.

The 'Non-Stick' Property Explained

PTFE, widely known by the brand name Teflon®, is a fluoropolymer. Its structure consists of a chain of carbon atoms completely shielded by a sheath of fluorine atoms.

These carbon-fluorine bonds are exceptionally strong and stable. This chemical stability is what gives PTFE its remarkable resistance to nearly all chemicals and high temperatures.

This same stability also results in extremely low surface energy. Adhesives work by "wetting" a surface, meaning the liquid adhesive spreads out and makes intimate contact. PTFE's low energy causes liquids, including adhesives, to bead up and refuse to spread, preventing any meaningful bond from forming.

Why Standard Adhesion Fails

For an adhesive to create a strong bond, it requires two things: a clean surface and sufficient surface energy to allow wetting.

With untreated PTFE, the adhesive simply cannot grip the surface at a molecular level. Any bond that does form would be purely mechanical and far too weak to withstand the physical stresses, temperature fluctuations, and chemical exposure inside an industrial tank.

How Surface Treatment Enables Bonding

The surface treatment process is not a coating; it is a permanent chemical modification of the PTFE itself. It is performed only on the side of the sheet that will be bonded to the tank wall.

The Chemical Etching Process

The most common method for treating PTFE is a chemical process known as etching. The sheet's back side is exposed to a solution, often involving sodium, that reacts with the PTFE.

This reaction breaks the strong carbon-fluorine bonds and strips fluorine atoms away from the surface.

Creating a Bondable Layer

This process leaves behind a carbonaceous, or carbon-rich, layer. This new surface is visually distinct, often turning a brownish color.

Crucially, this altered layer has much higher surface energy. It becomes receptive to adhesives, allowing them to properly wet the surface and form a powerful, permanent chemical bond. The front, untreated side remains a pure, chemically inert PTFE surface.

Understanding the Critical Implications

Failing to use a properly treated sheet or underestimating the importance of the bond has severe consequences in a tank lining application.

The Bond is Part of the System

The liner, adhesive, and tank wall work together as a single integrated system. The adhesive bond is not merely for positioning; it is a structural component.

A strong, uniform bond prevents the liner from buckling under thermal expansion, collapsing under vacuum conditions, or tearing. It ensures the liner remains flush against the tank wall, functioning as intended.

The Consequence of a Failed Bond

If the bond between the liner and the tank fails, a gap can form. Corrosive chemicals can permeate this space, becoming trapped behind the liner.

This leads to a catastrophic and hidden failure mode. The trapped chemicals will attack the tank's metal shell, causing corrosion that is invisible from the outside. By the time the leak is discovered, the structural integrity of the tank may already be compromised.

Making the Right Choice for Your Application

The decision to use surface-treated PTFE is not a matter of preference but a fundamental requirement for success and safety in tank lining.

- If your primary focus is safety and long-term reliability: Always specify and verify that the PTFE sheet is professionally surface-treated on one side for bonding. This is a non-negotiable step for any critical containment application.

- If your primary focus is system integrity: Treat the adhesive selection and surface preparation with the same rigor as the liner selection itself. The bond is as critical to performance as the PTFE material.

Ultimately, surface treatment is the enabling technology that allows us to leverage the extraordinary protective properties of PTFE in demanding industrial environments.

Summary Table:

| Aspect | Untreated PTFE | Surface-Treated PTFE |

|---|---|---|

| Surface Energy | Extremely Low | Significantly Increased |

| Adhesive Wetting | Poor (Beads Up) | Excellent (Spreads Evenly) |

| Bond Strength | Weak, Mechanical Only | Strong, Chemical Bond |

| Application Safety | High Risk of Liner Failure | Reliable, Long-Term Performance |

Ensure the integrity and safety of your tank lining system with KINTEK's precision-manufactured PTFE components.

Our PTFE sheets are expertly surface-treated to guarantee a permanent, reliable bond for your most critical containment applications in the semiconductor, medical, laboratory, and industrial sectors. We provide custom fabrication from prototypes to high-volume orders, ensuring your liners perform as an integrated system.

Contact us today via our secure form to discuss your project requirements and receive a quote.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Bottles for Diverse Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What support is available for selecting the right PTFE valve design and size? Get Expert Guidance for Your Application

- What are the key considerations when choosing between pure PTFE and additive-enhanced PTFE in valve manufacturing? Optimize Performance and Purity

- What is a Teflon O-ring? A Guide to PTFE Seals for Extreme Chemical and Temperature Resistance

- What are the advantages of PTFE packing over graphite packing? Maximize Chemical Resistance & Purity

- What support and warranty options are available for custom Teflon parts? Secure Your Investment with Full Manufacturer Backing

- What are the mechanical applications of PTFE rods? Solve Friction and Corrosion Problems

- What aerospace applications utilize Teflon plastic sheets? Critical Components for Extreme Environments

- What are the benefits of using PTFE gasket sheet material? Superior Sealing for Demanding Industries