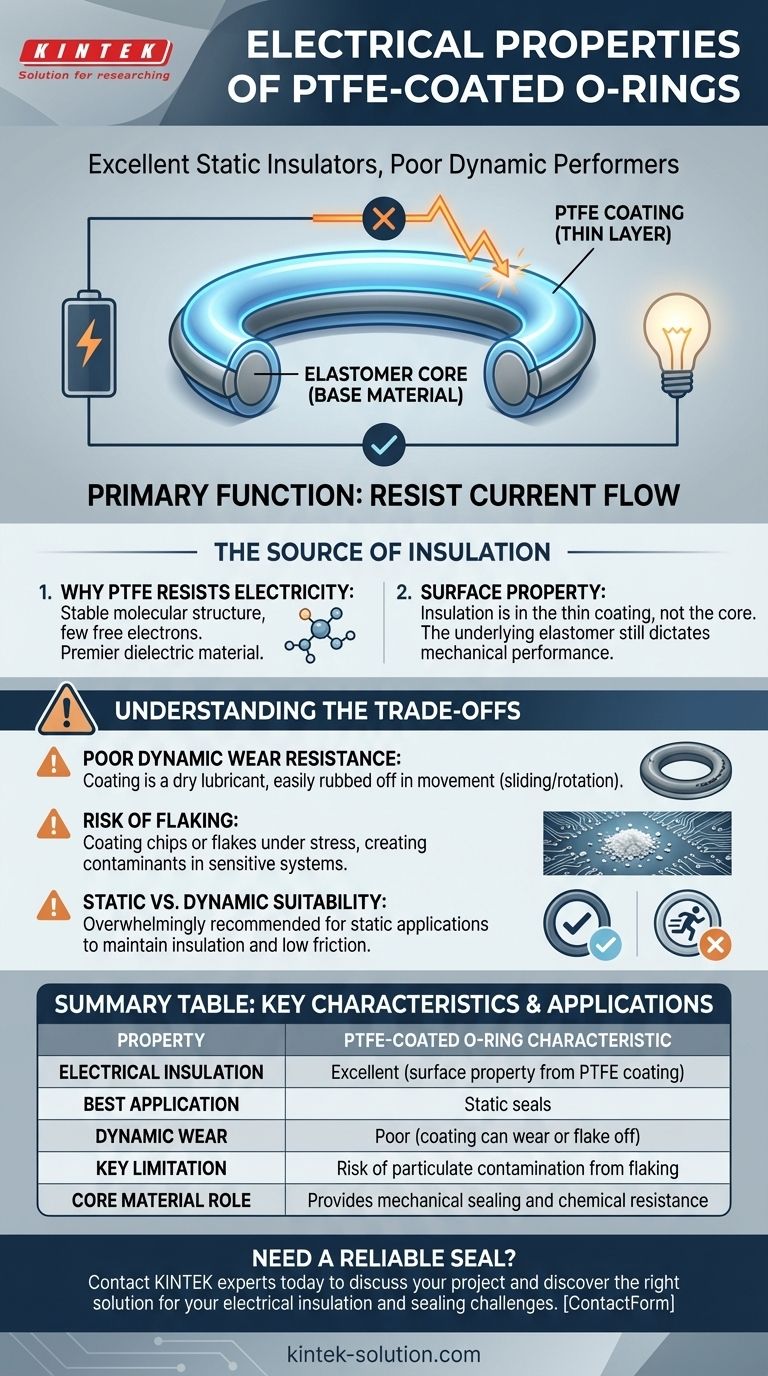

Fundamentally, PTFE-coated O-rings are excellent electrical insulators. This property is derived directly from the polytetrafluoroethylene (PTFE) layer applied to the surface of a standard elastomer O-ring. The coating's primary electrical function is to resist the flow of current, making these components highly suitable for applications where preventing electrical leakage across a sealed interface is critical.

The key insight is that while the PTFE coating provides superior surface insulation and low friction, its mechanical fragility is the deciding factor. The coating's electrical benefits can be negated if it wears away or flakes off, making these O-rings best suited for static, not dynamic, applications.

The Source of Electrical Insulation

Why PTFE Resists Electricity

PTFE is a fluoropolymer with an extremely stable molecular structure. This stability means there are very few free electrons to conduct an electrical current.

As a result, PTFE is a premier dielectric material, meaning it can sustain an electric field without conducting electricity. It is highly resistant to electrical tracking, where a current attempts to form a conductive path across an insulator's surface.

A Surface-Level Property

It is critical to understand that the electrical insulation is a property of the thin coating, not the entire O-ring.

The underlying elastomer (like FKM, Silicone, or EPDM) has its own set of electrical properties. The PTFE coating enhances the surface characteristics, but the bulk material of the O-ring still defines the component's overall mechanical performance and its behavior if the coating is compromised.

The Role of the Core Material

Porosity of the Coating

A PTFE coating is not a perfectly hermetic seal. It is slightly porous and is primarily there to reduce friction and provide surface insulation.

This means the coating does not add significant chemical or temperature resistance. The core elastomer must be independently selected to withstand the application's media and temperature range.

Mechanical Performance

The core material dictates the O-ring's fundamental sealing ability, including its compression set (the ability to rebound after being compressed) and elasticity.

If the coating were to wear away, the core material's properties would become the primary factor in both mechanical sealing and electrical insulation.

Understanding the Trade-offs and Limitations

Poor Dynamic Wear Resistance

This is the most significant limitation of PTFE-coated O-rings. The coating is a dry lubricant that can easily be rubbed off in dynamic applications involving sliding or rotation.

Once the coating is gone, its low-friction and electrical insulation benefits are lost. In many moving applications, it functions only as a one-time lubricant for initial installation.

The Risk of Flaking

The PTFE coating can chip or flake off, especially under stress or during movement.

These tiny flakes can become contaminants in sensitive systems, such as electronics, fuel lines, or medical devices. This particulate can clog small orifices or even create unintended conductive paths if it bridges two terminals.

Static vs. Dynamic Suitability

Due to these limitations, PTFE-coated O-rings are overwhelmingly recommended for static applications.

In a static face or groove seal, the coating provides excellent insulation and eases installation without the risk of being worn away.

Making the Right Choice for Your Application

Choosing the correct seal requires matching the component's properties to the specific demands of your design.

- If your primary focus is static electrical insulation: A PTFE-coated O-ring is an excellent and cost-effective choice, providing reliable surface insulation and low-friction installation.

- If your primary focus is dynamic sealing with insulation: Avoid PTFE-coated O-rings due to wear and flaking; instead, consider a solid PTFE O-ring or an elastomer known for its inherent dielectric properties.

- If your primary focus is system cleanliness: The risk of particulate contamination makes PTFE-coated O-rings a poor choice for sensitive electronic, medical, or optical systems.

Ultimately, you must evaluate the component not just for its ideal properties but also for its performance under real-world mechanical stress.

Summary Table:

| Property | PTFE-Coated O-Ring Characteristic |

|---|---|

| Electrical Insulation | Excellent (surface property from PTFE coating) |

| Best Application | Static seals |

| Dynamic Wear | Poor (coating can wear or flake off) |

| Key Limitation | Risk of particulate contamination from flaking |

| Core Material Role | Provides mechanical sealing and chemical resistance |

Need a reliable, high-performance seal for your application?

At KINTEK, we specialize in manufacturing precision PTFE components, including custom O-rings and seals, for the semiconductor, medical, laboratory, and industrial sectors. Our expertise ensures you get the right solution for your specific electrical insulation and sealing challenges, from prototypes to high-volume orders.

Contact our experts today to discuss your project requirements and discover how we can enhance your design's reliability and performance.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- Can both PTFE and stainless steel impellers be sterilized in an autoclave? Yes, and here's how to choose.

- In which industries are PTFE-lined piping systems commonly used? Ensure Safety and Purity in Harsh Environments

- How are PTFE gaskets and O-rings used in industrial and marine operations? Ensure Leak-Proof Sealing in Harsh Environments

- How does the durability of PTFE expansion bellows compare to rubber alternatives? Maximize Lifespan in Harsh Environments

- What industries rely heavily on Teflon machined parts? Critical Applications in Aerospace, Medical & More

- What is a PTFE lined dual plate check valve? A Guide to Corrosion-Resistant Backflow Prevention

- In what industries or applications are PTFE bellows commonly used? Essential for Purity and Corrosion Resistance

- In which industries are PTFE rotary shaft lip seals commonly used? Essential for Extreme Conditions