When choosing a manufacturer for PTFE-lined bearings, your primary consideration must be their documented experience and technical expertise in the liner bonding process. This single factor is the most common point of failure, where improper adhesion can lead to liner separation, rapid degradation, and catastrophic failure of the entire assembly.

The decision is not merely about procuring a component; it's about selecting a specialized engineering partner. The right manufacturer brings critical expertise in material science, custom design, and collaborative problem-solving to ensure the bearing meets the unique and demanding constraints of your specific application.

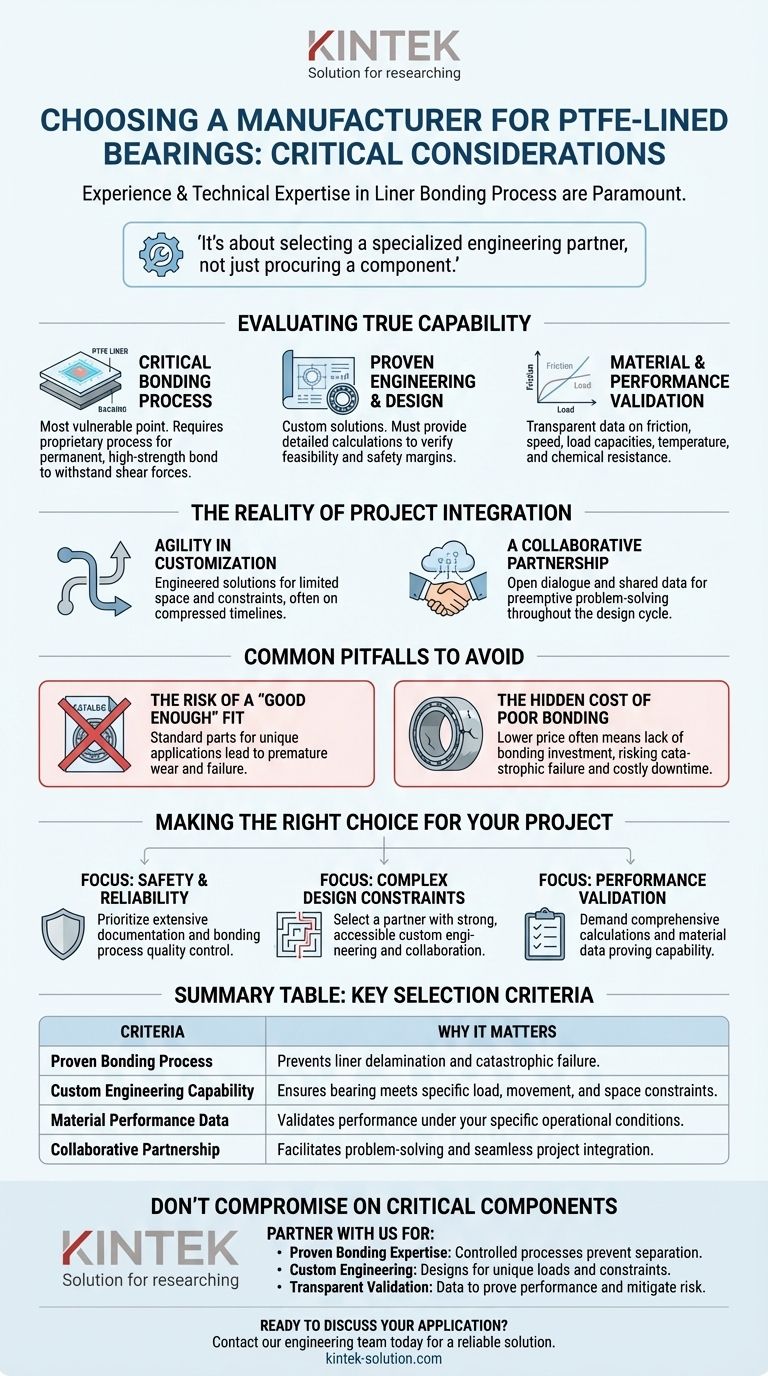

Beyond the Spec Sheet: Evaluating True Capability

A bearing's performance is defined by more than its data sheet. A manufacturer's true value lies in their process control, engineering depth, and ability to validate their product against your specific operational parameters.

The Critical Bonding Process

The bond between the PTFE liner and the bearing's backing is the component's most vulnerable point. A failure here is not a gradual decline; it is often a rapid and complete loss of function.

An experienced manufacturer will have a highly controlled, proprietary process for preparing the backing material and applying the liner to ensure a permanent, high-strength bond that can withstand the application's shear forces.

Proven Engineering and Design

PTFE bearings are rarely off-the-shelf parts. They are engineered solutions for specific challenges. The manufacturer must demonstrate the ability to translate your requirements—vertical loads, movement ranges, rotation, and potential uplift—into a viable design.

This involves providing detailed calculations based on established material properties to verify the design's feasibility and safety margins long before production begins.

Material and Performance Validation

A reputable manufacturer provides transparent data on their material's performance. They should be able to clearly define the bearing's capabilities under specific conditions.

This includes its coefficient of friction, maximum sliding speeds, and load capacities (both static and dynamic). It also extends to performance in your project's specific operational temperatures and potential exposure to chemical media.

The Reality of Project Integration

Bearings are often considered late in the design cycle, creating significant integration challenges. A manufacturer's ability to adapt and collaborate is just as important as their technical skill.

Agility in Customization

Real-world projects impose constraints, such as limited space, specific superstructure gaps, or restrictions on installation methods like welding or bolting.

A key indicator of a superior manufacturer is their ability to engineer customized solutions that work within these limitations, often on a compressed timeline. They see these constraints as part of the engineering problem to be solved.

A Collaborative Partnership

The most successful outcomes occur when the bearing manufacturer acts as a partner, not just a supplier. This requires a clear commitment to transparency from both sides.

Look for a manufacturer who engages in open dialogue, shares data freely, and works with your team throughout the product design and integration cycle to preemptively solve problems.

Common Pitfalls to Avoid

Choosing a partner based solely on initial cost or a generic spec sheet introduces significant risk. Understanding the potential downsides is critical for avoiding costly failures.

The Risk of a "Good Enough" Fit

Attempting to use a standard, catalog bearing for a unique application is a false economy. The subtle mismatches in load capacity, movement tolerance, or material compatibility can lead to premature wear and failure.

True cost-effectiveness comes from an engineered solution designed precisely for the intended use case.

The Hidden Cost of Poor Bonding

A lower price from a less experienced manufacturer often reflects a lack of investment in the critical bonding process.

While this may save money upfront, a single instance of liner delamination can cause damage to surrounding structures or machinery, leading to downtime and repair costs that dwarf the initial savings.

Making the Right Choice for Your Project

Selecting a manufacturer is a strategic decision that directly impacts project reliability and safety. Use your specific project goals to guide your evaluation.

- If your primary focus is safety and long-term reliability: Prioritize manufacturers who can provide extensive documentation and history of their liner bonding process and quality control.

- If your primary focus is navigating complex design constraints: Select a partner with a strong, accessible engineering team that emphasizes custom solutions and collaborative problem-solving.

- If your primary focus is performance validation for a demanding application: Demand comprehensive calculations and material data that prove the bearing can handle your specific loads, movements, and environmental conditions.

Ultimately, choosing the right manufacturer is about mitigating risk by investing in proven engineering expertise.

Summary Table:

| Key Selection Criteria | Why It Matters |

|---|---|

| Proven Bonding Process | Prevents liner delamination and catastrophic failure. |

| Custom Engineering Capability | Ensures the bearing meets specific load, movement, and space constraints. |

| Material Performance Data | Validates performance under your specific operational conditions. |

| Collaborative Partnership | Facilitates problem-solving and seamless project integration. |

Don't Compromise on Critical Components

Your project's safety and reliability depend on the quality of your PTFE-lined bearings. At KINTEK, we specialize in manufacturing high-performance PTFE components for the semiconductor, medical, laboratory, and industrial sectors. Our expertise in precision production and custom fabrication—from prototypes to high-volume orders—ensures a permanent, high-strength bond and a bearing solution engineered for your exact requirements.

Partner with us for:

- Proven Bonding Expertise: Our controlled processes prevent liner separation.

- Custom Engineering: We design solutions for your unique loads and constraints.

- Transparent Validation: We provide the data to prove performance and mitigate risk.

Ready to discuss your specific application? Contact our engineering team today for a collaborative partnership and a reliable solution.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

People Also Ask

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- Why is PTFE rod suitable for automotive applications? Boost Vehicle Performance & Durability

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs