Yes, pure PTFE sheets are widely considered safe for food-related uses. The material is chemically inert, non-toxic, and approved by the FDA for direct food contact. This makes it a popular choice for applications ranging from reusable baking sheets to components in industrial food processing equipment.

The critical factor determining food safety is the grade of the material. Only 100% pure, virgin PTFE is approved for food applications, as industrial grades may contain fillers that can contaminate or taint food.

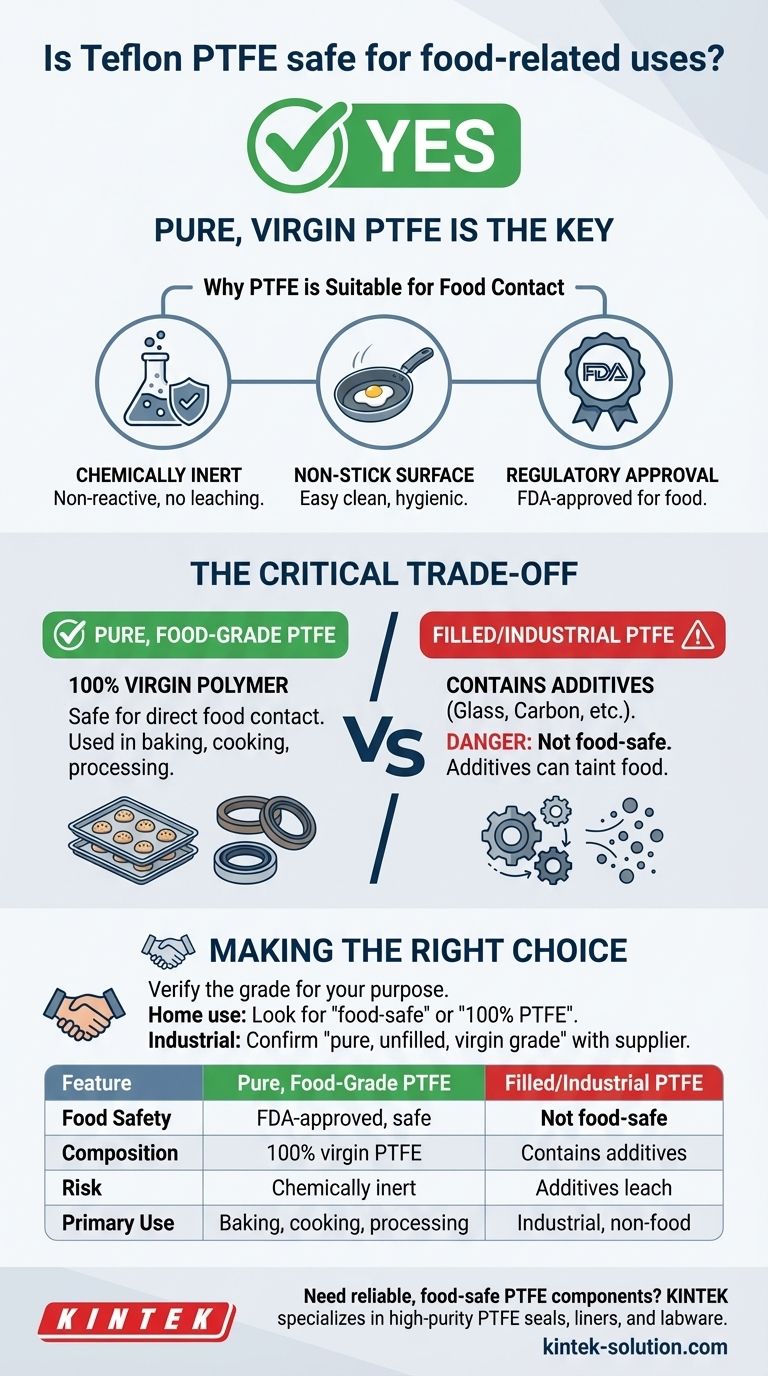

Why PTFE is Suitable for Food Contact

Polytetrafluoroethylene (PTFE), commonly known by the brand name Teflon, possesses unique properties that make it highly valuable in food environments. Its safety and utility are rooted in its fundamental chemical structure.

Chemical Inertness

Pure PTFE is one ofthe most chemically inert polymers known. It does not react with food acids, bases, or fats.

This non-reactive nature ensures that the material will not break down and leach harmful substances into the food it touches, preventing contamination.

Non-Stick Surface

The famous non-stick quality of PTFE is a significant advantage for food safety and hygiene.

Because food does not adhere to the surface, components are much easier to clean thoroughly. This reduces the risk of bacterial growth and cross-contamination in both home kitchens and industrial settings.

Regulatory Approval

Materials intended for food contact are subject to strict regulatory oversight.

PTFE is approved by the U.S. Food and Drug Administration (FDA) for use in food applications, confirming its status as a non-toxic and safe material when used as intended.

The Critical Trade-off: Pure vs. Filled PTFE

While pure PTFE is safe, not all PTFE is created equal. The distinction between pure and filled grades is the single most important factor for any food-related use case.

Pure, Food-Grade PTFE

This is the only type of PTFE that should ever come into contact with food. It consists of 100% virgin PTFE polymer without any additives.

Products intended for baking, cooking, or food processing will always be made from this pure grade to meet safety standards.

The Dangers of Filled Grades

For industrial applications outside of the food industry, fillers like glass, carbon, or bronze are often added to PTFE to enhance its strength or wear resistance.

These filled grades are not food-safe. The additives can discolor, taint, or leach into food, making them entirely unsuitable for these applications.

Common Food-Related Applications

The properties of pure PTFE make it a versatile material across the food industry, from consumer products to large-scale processing.

Baking and Crafting Sheets

Reusable, non-stick sheets made from PTFE are common in baking. They provide an excellent surface for cookies, pastries, and other baked goods, eliminating the need for oils or single-use parchment paper.

Industrial Gaskets and Seals

In commercial dairy and beverage processing, PTFE is used for gaskets and seals within pipes and machinery.

Its inertness ensures that it does not contaminate the liquids flowing through the system, maintaining the purity of the final product.

Making the Right Choice for Your Goal

To ensure safety, you must verify that you are using the correct grade of PTFE for your specific purpose.

- If your primary focus is home baking or cooking: Purchase sheets or liners that are explicitly marketed as "food-safe," "FDA-approved," or "100% PTFE" for culinary use.

- If your primary focus is industrial food processing: Always confirm with your supplier that the material is a pure, unfilled, virgin grade of PTFE designed specifically for direct food contact applications.

By ensuring you are using only pure, food-grade PTFE, you can confidently leverage its unique benefits in any food-related application.

Summary Table:

| Feature | Pure, Food-Grade PTFE | Filled/Industrial PTFE |

|---|---|---|

| Food Safety | FDA-approved, safe for direct contact | Not food-safe |

| Composition | 100% virgin PTFE polymer | Contains additives (glass, carbon, etc.) |

| Risk of Contamination | Chemically inert, non-toxic | Additives can leach and taint food |

| Primary Use | Baking, cooking, food processing | Industrial, non-food applications |

Need reliable, food-safe PTFE components? KINTEK specializes in manufacturing high-purity PTFE seals, liners, and custom labware for the food, beverage, and pharmaceutical industries. Our commitment to precision and using only certified, virgin materials ensures your products meet the strictest safety standards. Contact our experts today to discuss your custom fabrication needs, from prototypes to high-volume orders.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Bottles for Diverse Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- How do energized PTFE seals work? Achieve Reliable Sealing from Zero to High Pressure

- What makes PTFE butterfly valves special compared to other types? Unmatched Chemical & Thermal Performance

- What are the benefits of using PTFE liners in medical procedures? Enhance Safety & Performance

- What makes Metal-Polymer Bronze Backed PTFE Plain Bearings corrosion resistant? A Two-Layer Defense System Explained

- How is PTFE adapted for semiconductor environments? Leveraging Inertness and Anti-Static Grades for Chip Fab

- Why is PTFE difficult to process using traditional methods? Overcoming High Melt Viscosity

- What is the process flow for PTFE compression molding? A 4-Step Guide to Durable PTFE Preforms

- What are the benefits of using PTFE lined check valves in water pump systems? Boost Reliability & Cut Costs