In short, the primary benefits of using PTFE-lined check valves in water pump systems are superior corrosion resistance, the absolute prevention of damaging backflow, and a significant reduction in long-term operational costs. These valves provide a durable, low-maintenance solution that protects critical system components like pumps and pipelines.

The true value of a PTFE-lined check valve lies not in a single feature, but in how its unique material properties—chemical inertness and a non-stick surface—work together to create a highly reliable, efficient, and cost-effective component for the entire lifespan of your water system.

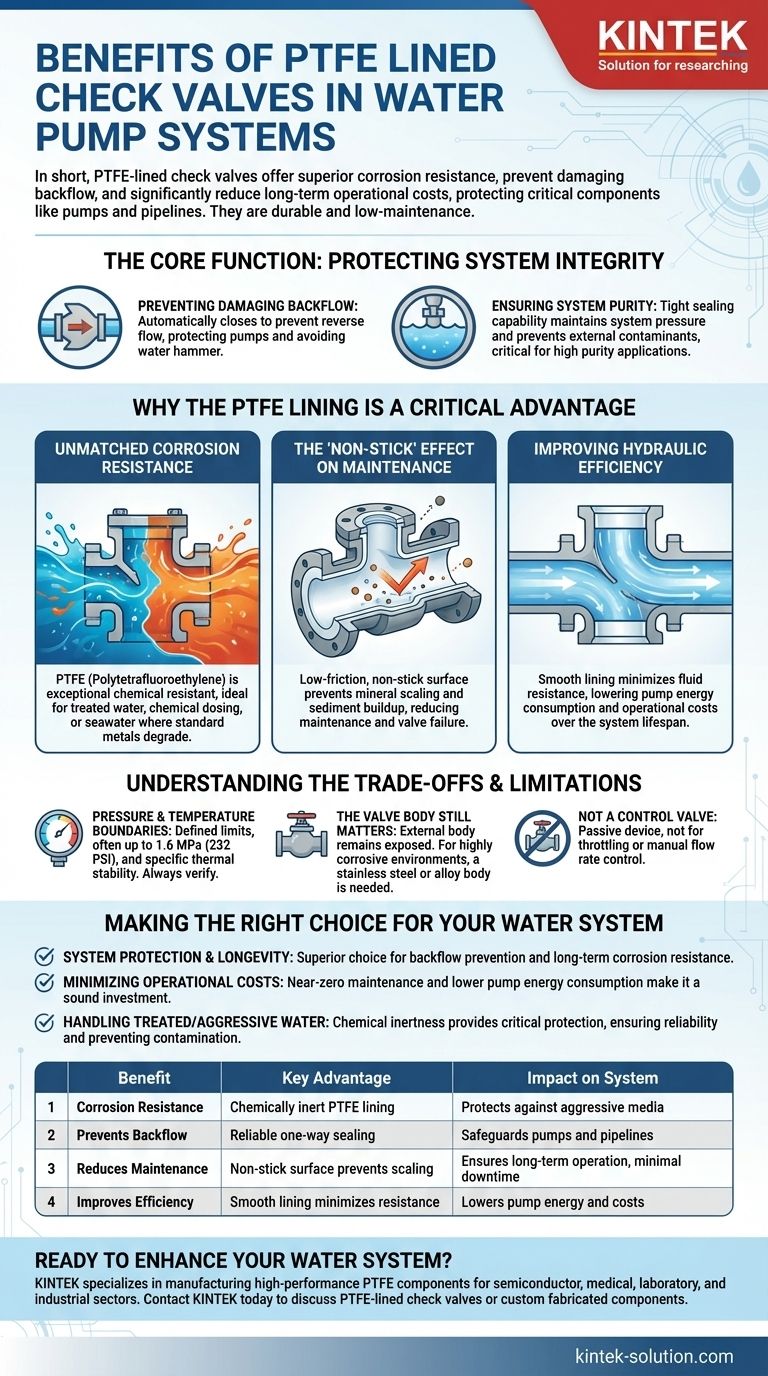

The Core Function: Protecting Your System Integrity

A check valve is your system's first line of defense against reverse flow. The addition of a PTFE lining elevates this function by ensuring the valve operates reliably under a wide range of conditions.

Preventing Damaging Backflow

A check valve's fundamental purpose is to allow fluid to flow in only one direction.

It automatically closes to prevent any reverse flow, which can cause catastrophic damage to pumps, create dangerous water hammer effects, and compromise the entire pipeline.

Ensuring System Purity

The effective sealing capability of these valves is critical for maintaining system pressure and preventing leakage.

This tight seal also ensures that no external contaminants can enter the water system, which is vital for applications requiring high purity.

Why the PTFE Lining is a Critical Advantage

While the mechanical action of a check valve is simple, the PTFE lining provides chemical and physical properties that drastically improve its performance, longevity, and efficiency.

Unmatched Corrosion Resistance

Polytetrafluoroethylene (PTFE) is a fluoropolymer that is exceptionally resistant to chemical attack and corrosion.

This makes the valve ideal for systems involving treated water, chemical dosing, or even more aggressive media like seawater, where standard metal components would quickly degrade.

The 'Non-Stick' Effect on Maintenance

PTFE has an extremely low-friction, non-stick surface. This property prevents mineral scaling, sediment, or other media from building up on the valve's internal components.

This lack of buildup ensures the valve's checking mechanism moves freely and seals properly over time, drastically reducing maintenance needs and preventing valve failure.

Improving Hydraulic Efficiency

The smooth, non-stick lining minimizes fluid resistance as water passes through the valve.

This improved flow characteristic reduces the energy required by the pump to move the fluid, leading to lower energy consumption and operational savings over the life of the system.

Understanding the Trade-offs and Limitations

To make an informed decision, it's essential to recognize where these valves excel and what their operational boundaries are. Objectivity is key to proper system design.

Pressure and Temperature Boundaries

While robust, PTFE-lined valves have defined operational limits. Many are rated for pressures up to 1.6 MPa (or 232 PSI).

They also possess high thermal stability, but you must always verify that the specific valve's temperature rating is suitable for your system's operating conditions.

The Valve Body Still Matters

The PTFE lining protects the wetted internal surfaces, but the external valve body is still exposed to the ambient environment.

For highly corrosive environments, such as marine or chemical plant applications, a PTFE-lined valve with a stainless steel body or other resistant alloy is necessary for overall durability.

Not a Control Valve

It is crucial to remember that a check valve is a passive, automatic device. It is not designed for throttling or manually controlling the rate of flow. Attempting to use it as such will lead to premature wear and system inefficiency.

Making the Right Choice for Your Water System

Selecting the right valve is a strategic decision. Base your choice on your system's primary operational goal.

- If your primary focus is system protection and longevity: A PTFE-lined check valve is a superior choice for preventing backflow damage while resisting long-term corrosion.

- If your primary focus is minimizing operational costs: The combination of near-zero maintenance requirements and lower pump energy consumption makes this valve a sound financial investment.

- If your primary focus is handling treated or aggressive water: The chemical inertness of PTFE provides critical protection that unlined metal valves cannot, ensuring reliability and preventing contamination.

Ultimately, specifying a PTFE-lined check valve is a proactive measure to enhance the core reliability and efficiency of your entire water pump system.

Summary Table:

| Benefit | Key Advantage | Impact on System |

|---|---|---|

| Corrosion Resistance | Chemically inert PTFE lining | Protects against aggressive media like treated water or chemicals |

| Prevents Backflow | Reliable one-way sealing mechanism | Safeguards pumps and pipelines from damage |

| Reduces Maintenance | Non-stick surface prevents scaling | Ensures long-term, reliable operation with minimal downtime |

| Improves Efficiency | Smooth lining minimizes flow resistance | Lowers pump energy consumption and operational costs |

Ready to enhance your water system's reliability and efficiency?

KINTEK specializes in manufacturing high-performance PTFE components, including custom check valves, for the semiconductor, medical, laboratory, and industrial sectors. Our precision engineering ensures your system benefits from superior corrosion resistance, reduced maintenance, and long-term cost savings.

Contact KINTEK today to discuss your specific requirements for PTFE-lined check valves or other custom fabricated components, from prototypes to high-volume orders.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

People Also Ask

- What is the hardness range of PTFE on the Shore D scale? Leveraging Its Softness for Superior Performance

- When and by whom was PTFE discovered? A Tale of Accidental Innovation

- Why is PTFE considered a significant discovery? A Material That Revolutionized Industry

- What is the temperature range that PTFE can withstand? From -200°C to +260°C for Demanding Applications

- How is PTFE used in industrial processes? Maximize Safety and Efficiency