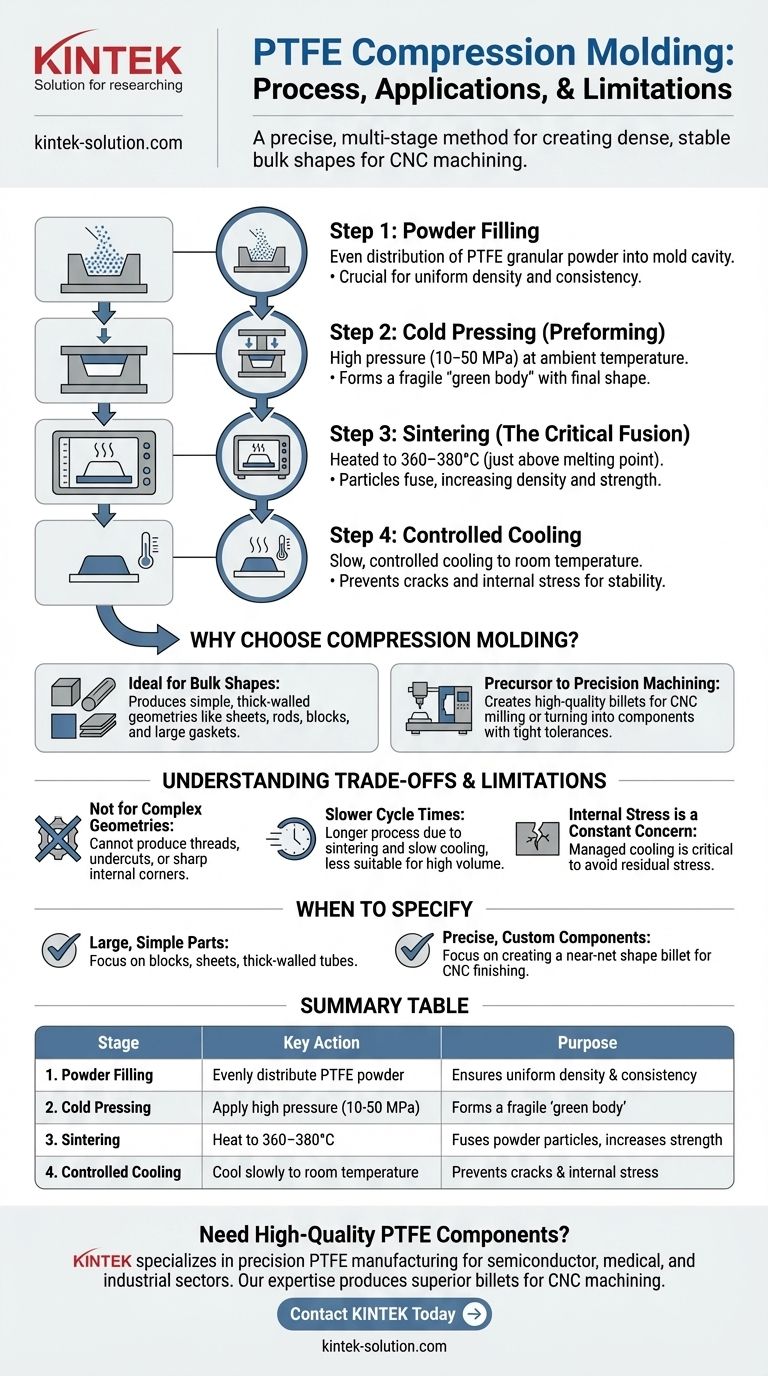

The process flow for PTFE compression molding is a precise, multi-stage method involving four key steps. First, PTFE powder is carefully filled into a mold. Second, this powder is subjected to high pressure in a step called cold pressing to form a fragile "green" part. Third, the part is heated in a process called sintering, which fuses the powder particles together. Finally, it undergoes a slow, controlled cooling phase to solidify into a stable final form.

PTFE compression molding is not primarily used to create finished, intricate parts. Instead, its core function is to produce dense, stable, and simple bulk shapes—like rods, sheets, or blocks—which serve as high-quality preforms for subsequent CNC machining to achieve precise final dimensions.

A Step-by-Step Breakdown of the Process

Understanding each stage of the compression molding process is critical to appreciating why it's chosen for specific applications and what determines the quality of the final product.

Stage 1: Powder Filling

The process begins by evenly distributing a pre-measured amount of PTFE granular powder into a mold cavity.

The uniformity of this distribution is crucial, as it directly impacts the density and consistency of the final part. Uneven filling can lead to weak spots or dimensional inaccuracies.

Stage 2: Cold Pressing (Preforming)

Once the mold is filled, a press applies significant pressure, typically between 10 and 50 MPa. This is done at ambient temperature.

This step compacts the powder particles, forcing them into tight mechanical contact and creating a fragile, self-supporting shape known as a green body. This part has its final shape but none of its final material properties.

Stage 3: Sintering (The Critical Fusion)

The green body is carefully removed from the mold and placed into a specialized oven for sintering.

The part is heated to a precise temperature between 360–380°C, which is just above PTFE's melting point. The material does not truly liquefy; instead, the individual particles fuse together, eliminating voids and dramatically increasing the part's density and mechanical strength.

Stage 4: Controlled Cooling

After sintering, the part must be cooled back to room temperature very slowly and under controlled conditions.

PTFE has a high rate of thermal expansion and contraction. Rapid cooling would induce significant internal stresses, causing cracks and compromising the structural integrity of the part. This slow cooling phase is essential for producing a stable, stress-free component.

Why Choose Compression Molding for PTFE?

This seemingly complex process is the go-to method for PTFE for several key reasons that align with the material's unique properties and common applications.

Ideal for Bulk Shapes

Compression molding excels at producing simple, thick-walled geometries. It is the most effective method for creating stock materials like sheets, rods, blocks, and large gaskets.

A Precursor to Precision Machining

The most common application of this process is not to make a final part, but to create a high-quality billet. This dense, stable block or rod is then transferred to a CNC machine for milling or turning into a component with tight tolerances.

This two-step approach (mold then machine) is often more economical and effective than trying to mold a complex PTFE part directly.

Understanding the Trade-offs and Limitations

While effective, this process carries inherent limitations that make it unsuitable for certain applications. Acknowledging these trade-offs is key to making an informed decision.

Not for Complex Geometries

The nature of pressing powder into a simple cavity means this process cannot produce intricate features like threads, sharp internal corners, or undercuts. The part geometry must be simple enough to be pressed and ejected.

Slower Cycle Times

The combination of sintering and, more importantly, the very slow cooling phase results in long cycle times. This makes the process less suitable for high-volume production compared to thermoplastic injection molding.

Internal Stress Is a Constant Concern

Properly managing the cooling cycle is the single most critical variable for part quality. Even with careful control, residual internal stress can be a factor, which is why machining is often performed on annealed (stress-relieved) material.

When to Specify PTFE Compression Molding

Choosing the right manufacturing process depends entirely on your end goal. Use these guidelines to determine if compression molding is the correct path for your project.

- If your primary focus is producing large, simple parts like blocks, sheets, or thick-walled tubes: Compression molding is the most effective and often the only viable manufacturing method.

- If your primary focus is manufacturing a precise, custom component with specific tolerances: Specify compression molding to create a near-net shape billet, which will then be finished via CNC machining.

Understanding this two-stage approach—molding a preform then machining it to final spec—is the key to successfully leveraging PTFE's unique properties for your application.

Summary Table:

| Stage | Key Action | Purpose |

|---|---|---|

| 1. Powder Filling | Evenly distribute PTFE powder into a mold | Ensures uniform density and consistency in the final part |

| 2. Cold Pressing | Apply high pressure (10-50 MPa) at room temperature | Forms a fragile 'green body' with the desired shape |

| 3. Sintering | Heat the part to 360–380°C | Fuses powder particles, increasing density and strength |

| 4. Controlled Cooling | Cool slowly to room temperature | Prevents cracks and internal stress for a stable final part |

Need High-Quality PTFE Components?

KINTEK specializes in precision PTFE manufacturing for the semiconductor, medical, laboratory, and industrial sectors. Our expertise in compression molding produces superior billets—rods, sheets, and blocks—perfect for your subsequent CNC machining into precise final components.

We offer custom fabrication from prototypes to high-volume orders, ensuring your parts meet exact specifications.

Contact KINTEL today to discuss your PTFE project requirements and get a quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- What are the main advantages of using PTFE parts in industrial applications? Unlock Unmatched Chemical Resistance and Reliability

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech