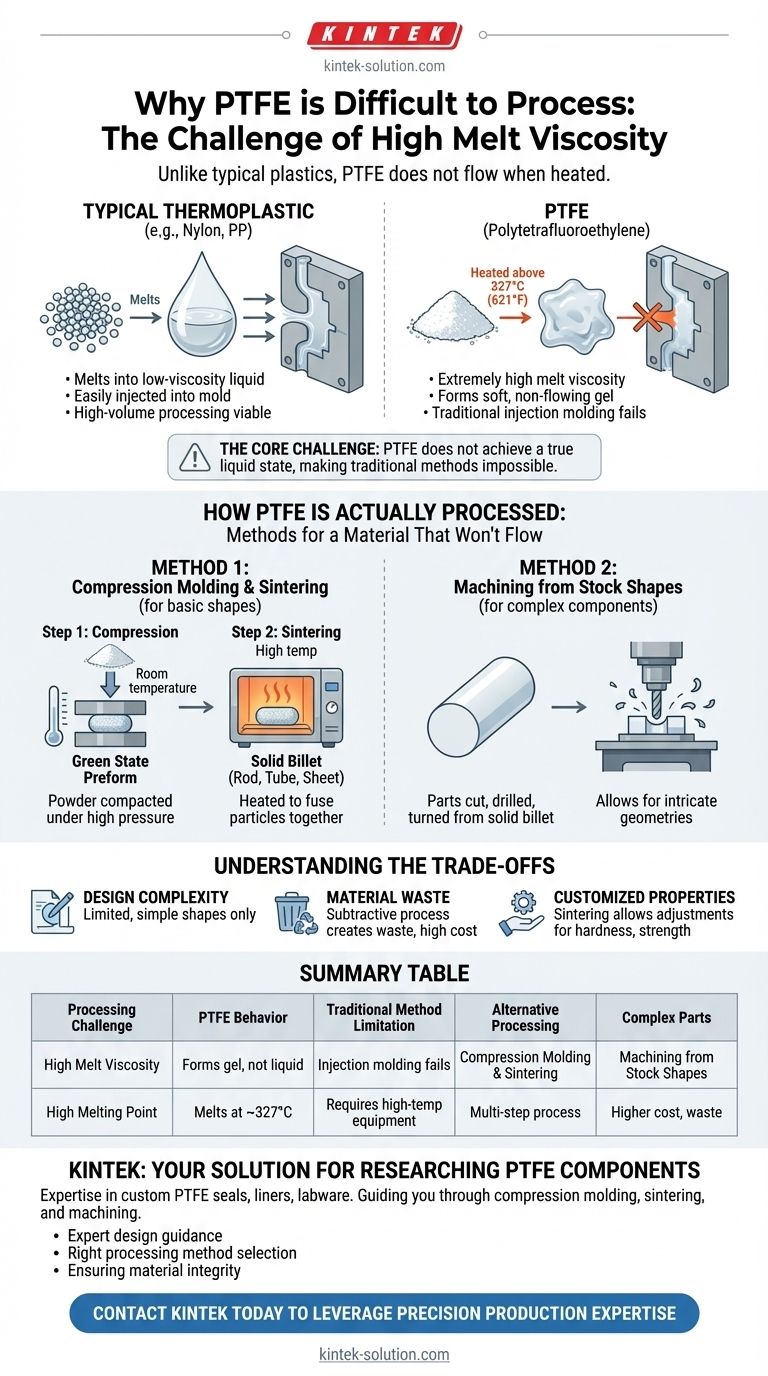

At its core, the difficulty in processing Polytetrafluoroethylene (PTFE) stems from two fundamental material properties: an extremely high melting point and, more critically, an exceptionally high melt viscosity. Unlike common plastics that liquefy and flow easily when heated, PTFE does not; it transitions into a soft, non-flowing gel that cannot be forced into a mold using conventional methods.

The central issue is that PTFE does not behave like a typical thermoplastic. It fails to achieve a true liquid state when melted, making traditional high-volume processing techniques like injection molding completely unviable and requiring specialized, multi-step methods instead.

The Core Challenge: A Material That Won't Flow

The primary obstacle in working with PTFE is not just its heat resistance, but its behavior at that high temperature. This unique characteristic dictates every aspect of how it must be handled and formed.

What "High Melt Viscosity" Really Means

Viscosity is a measure of a fluid's resistance to flow. While plastics like polypropylene or nylon melt into a low-viscosity liquid that can be easily injected into a mold, PTFE does the opposite.

When heated above its melting temperature of approximately 327°C (621°F), PTFE maintains an extremely high viscosity. It becomes a translucent, gel-like substance that will not flow under pressure, making it impossible to process with standard equipment.

Why Injection Molding Fails

Injection molding relies on melting plastic pellets into a true liquid and then forcing that liquid under high pressure into a mold cavity.

Because PTFE never becomes a low-viscosity fluid, it simply cannot be processed this way. Attempting to do so would be like trying to inject a solid block of gelatin into a mold—it will not conform to the shape.

How PTFE Is Actually Processed

Since traditional melt processing is not an option, manufacturing with PTFE relies on methods more commonly associated with powdered metals or ceramics. These techniques work around the material's inability to flow.

Method 1: Compression Molding and Sintering

This is the most common method for creating basic PTFE shapes, known as "billets" (such as rods, tubes, or sheets).

It is a two-step process. First, PTFE resin powder is compressed under high pressure at room temperature into a preform shape. Second, this compacted shape is heated in an oven above its melting point in a process called sintering, which fuses the individual PTFE particles together into a solid mass.

Method 2: Machining from Stock Shapes

For more complex or high-precision components, the standard approach is to machine them from pre-existing stock shapes.

Parts are cut, drilled, or turned on a CNC machine from a solid billet that was previously created through compression molding and sintering. This allows for intricate geometries that molding cannot achieve.

Understanding the Trade-offs

The unique processing requirements of PTFE introduce specific design and cost considerations that are different from those for conventional plastics.

Design Complexity is Limited

Compression molding is best suited for simple, symmetrical shapes like seals, gaskets, and bearings. It cannot produce the fine details, sharp corners, or complex features that are possible with injection molding.

Machining Creates Material Waste

While machining allows for high precision, it is a subtractive process. A significant amount of the expensive PTFE stock material may be cut away and wasted, which can drive up the cost per part, especially for complex designs.

Properties Can Be Customized

A key advantage of the sintering process is that its parameters (temperature, duration, and cooling rate) can be adjusted. This allows for the customization of mechanical properties like hardness, tensile strength, and flexibility to meet specific application demands.

Making the Right Choice for Your Application

Understanding these processing constraints is the first step to leveraging PTFE's remarkable chemical resistance and low-friction properties effectively.

- If your primary focus is creating simple, robust shapes like seals or washers: Compression molding is the most direct and cost-effective manufacturing method.

- If your primary focus is producing a small number of complex, high-precision components: Machining from a pre-sintered stock shape is the most practical and often the only viable approach.

- If you are designing a new part: Acknowledge from the start that PTFE cannot be injection molded and design your component with the geometric limitations of molding and machining in mind.

By working with these unique manufacturing rules instead of against them, you can successfully harness the full potential of this high-performance material.

Summary Table:

| Processing Challenge | PTFE Behavior | Traditional Method Limitation |

|---|---|---|

| High Melt Viscosity | Forms a gel, not a liquid, when heated | Injection molding fails; material won't flow into mold |

| High Melting Point | Melts at ~327°C (621°F) | Requires specialized high-temperature equipment |

| Alternative Processing | Compression Molding & Sintering | Multi-step process, limited to simpler shapes |

| Complex Parts | Machining from Stock Shapes | Higher cost, significant material waste |

Need High-Quality PTFE Components? Let KINTEK's Expertise Guide You.

Understanding PTFE's unique processing challenges is just the first step. Successfully manufacturing precision parts requires a partner with specialized knowledge and capabilities.

KINTEK manufactures custom PTFE components—including seals, liners, and labware—for the semiconductor, medical, laboratory, and industrial sectors. We expertly navigate the complexities of compression molding, sintering, and precision machining to deliver parts that meet your exact specifications, from prototypes to high-volume orders.

We help you overcome PTFE's limitations by:

- Providing expert design guidance to optimize your part for manufacturability.

- Selecting the right processing method (molding or machining) to balance cost, complexity, and performance.

- Ensuring material integrity through controlled sintering processes that tailor mechanical properties.

Don't let processing challenges limit your design. Contact KINTEK today to discuss your PTFE component needs and leverage our precision production expertise.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Rods for Advanced Industrial Applications

- Custom PTFE Teflon Balls for Advanced Industrial Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

People Also Ask

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What are the best practices for achieving tight tolerances in Teflon (PTFE) machining? Master Precision for Demanding Applications

- What industries use PTFE machined parts and for what applications? Critical Components for Demanding Environments

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support