In short, PTFE butterfly valves are special due to their unique material properties that create an unparalleled combination of near-universal chemical resistance, high-temperature tolerance, and superior sealing performance. While other valves might excel in one area, PTFE-lined valves provide a robust, all-in-one solution for some of the most demanding industrial environments.

The core value of a PTFE butterfly valve isn't just its resistance to chemicals or heat, but its ability to deliver reliable, leak-free performance in aggressive applications where standard materials would corrode, degrade, and ultimately fail.

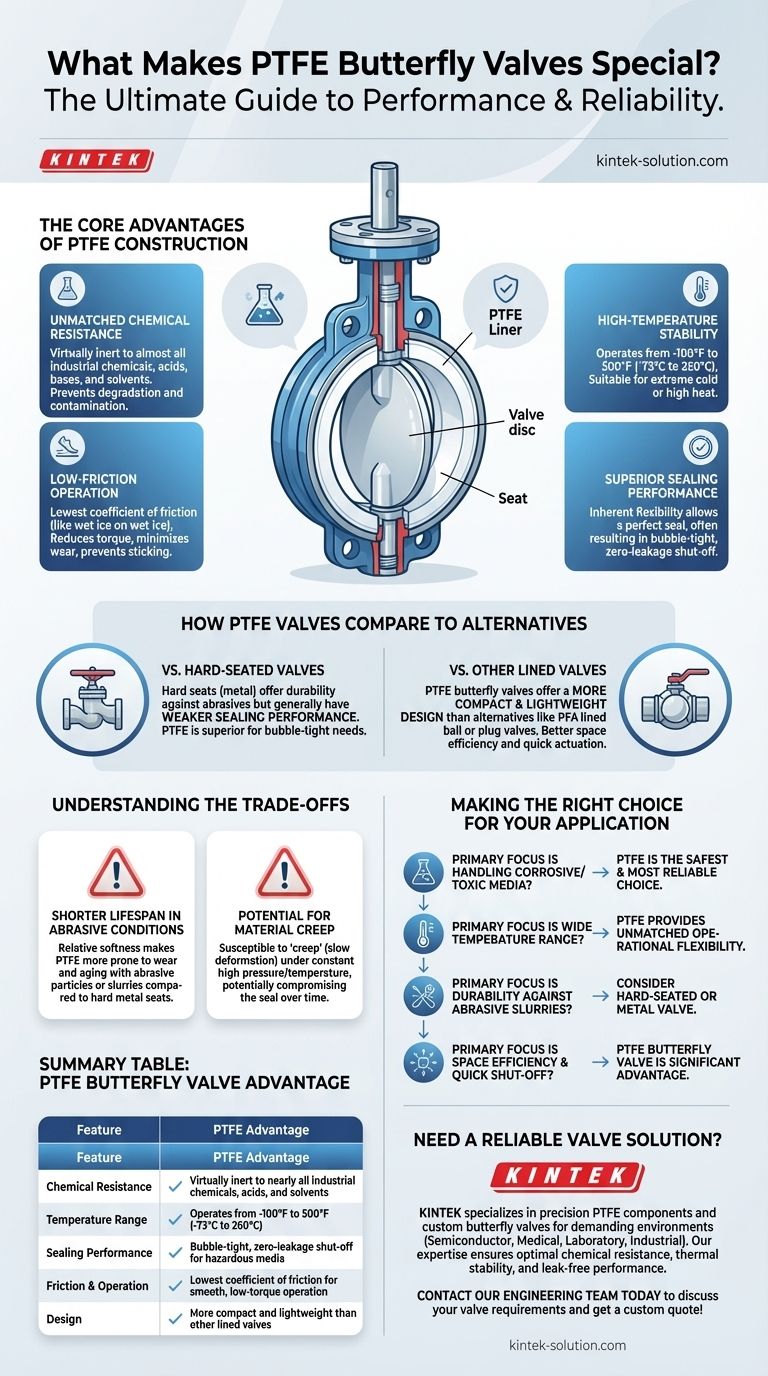

The Core Advantages of PTFE Construction

The unique characteristics of Polytetrafluoroethylene (PTFE) are what set these valves apart. This synthetic fluoropolymer provides a combination of benefits that directly translate to operational reliability and safety.

Unmatched Chemical Resistance

PTFE is virtually inert to almost all industrial chemicals. This includes highly corrosive acids, bases, solvents, and other aggressive substances.

This inertness prevents two critical problems: it stops the process media from degrading the valve's components and ensures the valve itself does not contaminate the media.

High-Temperature Stability

These valves operate effectively across an exceptionally wide temperature range, typically from -100°F to 500°F (-73°C to 260°C).

This makes them suitable for processes that involve extreme cold or high heat, providing a level of versatility that many standard elastomers cannot match.

Low-Friction Operation

PTFE has one of the lowest coefficients of friction of any solid material, similar to wet ice on wet ice.

This property reduces the torque required to open and close the valve, minimizing wear and tear on the seat and disc. It also helps prevent process media from sticking to the valve's internal surfaces.

Superior Sealing Performance

The inherent flexibility of PTFE allows the seat to conform perfectly to the valve disc, creating an exceptionally tight seal.

This often results in a "zero-leakage" shut-off, which is critical when handling toxic, hazardous, or high-purity fluids where any escape could be dangerous or costly.

How PTFE Valves Compare to Alternatives

While PTFE offers a powerful set of features, its advantages become clearer when compared to other common valve types.

Advantage Over Hard-Seated Valves

Valves with metal or "hard" seats are prized for their durability, especially with abrasive media. However, they generally offer weaker sealing performance compared to the "soft" seat of a PTFE valve.

When a bubble-tight shut-off is non-negotiable, PTFE is almost always the superior choice.

Advantage Over Other Lined Valves

Compared to alternatives like PFA-lined ball or plug valves, PTFE-lined butterfly valves offer a more compact and lightweight design.

This makes them more space-efficient and often better suited for applications requiring quick actuation for immediate shut-off, without sacrificing the necessary chemical resistance.

Understanding the Trade-offs

No single valve is perfect for every situation. Objectivity requires acknowledging the limitations of PTFE-lined valves to ensure they are used in the correct applications.

Shorter Lifespan in Abrasive Conditions

The primary trade-off for PTFE's excellent sealing is its relative softness. It is more prone to wear and aging than a hard metal seat, especially when the media contains abrasive particles or slurries.

In these conditions, a hard-seated valve will almost always have a longer operational lifespan.

Potential for Material Creep

Under constant high pressure and temperature, PTFE can be susceptible to "creep" or cold flow, where the material slowly deforms over time. This can eventually compromise the integrity of the seal.

Proper valve design and selection for the specific pressure and temperature ratings of the application are critical to mitigating this risk.

Making the Right Choice for Your Application

Selecting the correct valve hinges on clearly defining the most critical demand of your process.

- If your primary focus is handling corrosive chemicals or toxic media: PTFE's chemical inertness and zero-leakage sealing make it the safest and most reliable choice.

- If your primary focus is operating in a wide temperature range: PTFE's stability across extreme hot and cold provides unmatched operational flexibility.

- If your primary focus is durability against abrasive slurries: You should consider a hard-seated or metal butterfly valve, as PTFE's soft liner can wear more quickly.

- If your primary focus is space efficiency and quick shut-off: The compact design of a PTFE butterfly valve is a significant advantage over bulkier lined ball or plug valves.

Ultimately, selecting a PTFE butterfly valve is a strategic decision for applications where chemical and thermal resilience cannot be compromised.

Summary Table:

| Feature | PTFE Butterfly Valve Advantage |

|---|---|

| Chemical Resistance | Virtually inert to nearly all industrial chemicals, acids, and solvents |

| Temperature Range | Operates from -100°F to 500°F (-73°C to 260°C) |

| Sealing Performance | Bubble-tight, zero-leakage shut-off for hazardous media |

| Friction & Operation | Lowest coefficient of friction for smooth, low-torque operation |

| Design | More compact and lightweight than other lined valves |

Need a reliable valve solution for corrosive or high-temperature applications?

KINTEK specializes in manufacturing precision PTFE components, including custom butterfly valves designed for the most demanding environments in semiconductor, medical, laboratory, and industrial sectors. Our expertise in PTFE fabrication ensures you get optimal chemical resistance, thermal stability, and leak-free performance.

Whether you need prototypes or high-volume production, we deliver solutions that meet your exact specifications. Contact our engineering team today to discuss your valve requirements and get a custom quote!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- Custom PTFE Square Trays for Industrial and Laboratory Use

- Customizable PTFE Seals Filter Holders for Versatile Applications

People Also Ask

- What are the unique properties of PTFE? The 3 Pillars Driving Demand for High-Performance Parts

- What are the main applications of PTFE type Teflon? Unlock Its Versatility for Your Industry

- What finishing techniques are effective for machined Teflon parts? Achieve Functional Performance and Dimensional Stability

- What are the unique properties of PTFE? Unlock Unmatched Performance in Demanding Applications

- What factors should be considered when choosing between Nylon and PTFE? Select the Right Material for Your Application