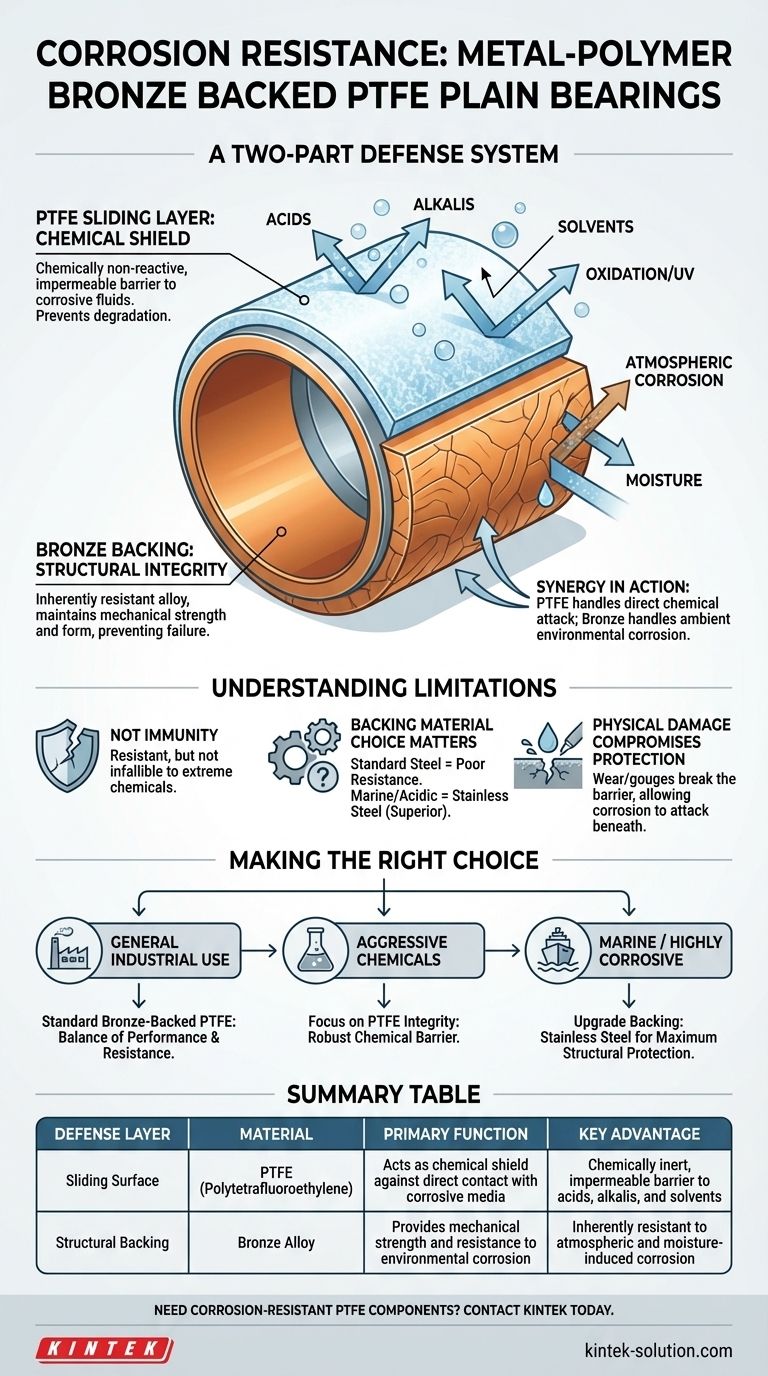

The corrosion resistance of a metal-polymer bronze-backed PTFE plain bearing is not derived from a single material, but from a two-part defense system. The bearing's resilience comes from the combination of the chemically inert PTFE sliding layer and the inherently corrosion-resistant bronze backing.

The core principle is layered protection. The PTFE layer acts as a complete chemical shield for the active contact surface, while the bronze backing provides foundational structural resistance against environmental corrosion like moisture.

A Two-Layer Defense Against Corrosion

To understand the bearing's durability, you must look at how its two primary components function independently and together to prevent degradation.

The PTFE Sliding Layer: A Chemical Shield

The primary defense is the layer of Polytetrafluoroethylene (PTFE), the material in direct contact with the moving parts.

PTFE is one of the most chemically non-reactive substances known. It acts as an impermeable barrier, preventing corrosive fluids, acids, or alkalis from ever reaching the metal structure beneath.

Its resistance to oxidation, weathering, and UV light ensures it does not degrade over time, even in harsh outdoor or chemical-rich environments.

The Bronze Backing: Structural Integrity

While the PTFE layer protects the sliding surface, the bearing's main body requires its own protection. This is the role of the bronze backing.

Bronze is an alloy that is significantly more resistant to atmospheric and moisture-induced corrosion than standard carbon steel.

This inherent resistance ensures the bearing maintains its mechanical strength and structural form, preventing failure from rust or degradation of the support structure.

How the Layers Work in Synergy

The design is highly effective because it addresses two different types of corrosive threats.

The PTFE layer handles direct chemical attack on the functional surface. The bronze backing handles ambient environmental corrosion that threatens the bearing's overall structure.

Understanding the Trade-offs and Limitations

While highly effective, this design is not infallible. Understanding its limitations is key to proper application.

It's Resistance, Not Immunity

Although PTFE is resistant to the vast majority of industrial chemicals, extremely aggressive or exotic combinations could potentially affect it. Always verify chemical compatibility in critical applications.

The Backing Material is a Critical Choice

The term "metal-polymer bearing" can be generic. While a bronze backing offers good protection, a bearing with a standard steel backing would have poor corrosion resistance. For marine or highly acidic environments, a stainless steel backing is the superior, albeit more expensive, option.

Physical Damage Can Compromise Protection

The system's primary weakness is mechanical damage. If the PTFE layer is worn through or gouged, the protective barrier is broken, and corrosive media can directly attack the bronze or sintered layer beneath.

Making the Right Choice for Your Application

Selecting the correct bearing depends entirely on matching its specific construction to the environmental challenges it will face.

- If your primary focus is general industrial use with moderate moisture: The standard bronze-backed PTFE bearing offers an excellent balance of performance and corrosion resistance.

- If your primary focus is exposure to aggressive chemicals: The integrity of the PTFE layer is your main concern, as it provides a robust chemical barrier for the sliding surface.

- If your primary focus is a marine or highly corrosive environment: Pay close attention to the backing material; upgrading from bronze to stainless steel is often necessary for maximum structural protection.

By understanding this two-part defense system, you can confidently select the right bearing for long-term reliability in your specific environment.

Summary Table:

| Defense Layer | Material | Primary Function | Key Advantage |

|---|---|---|---|

| Sliding Surface | PTFE (Polytetrafluoroethylene) | Acts as chemical shield against direct contact with corrosive media | Chemically inert, impermeable barrier to acids, alkalis, and solvents |

| Structural Backing | Bronze Alloy | Provides mechanical strength and resistance to environmental corrosion | Inherently resistant to atmospheric and moisture-induced corrosion |

Need corrosion-resistant PTFE components for your application?

At KINTEK, we specialize in manufacturing precision PTFE components (including seals, liners, labware, and custom bearings) for semiconductor, medical, laboratory, and industrial applications. Our expertise in custom fabrication—from prototypes to high-volume production—ensures you get components specifically engineered to withstand your unique environmental challenges.

Contact us today to discuss how our PTFE solutions can enhance the durability and performance of your equipment.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Customizable PTFE Seals Filter Holders for Versatile Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

People Also Ask

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- Why is CNC machining preferred for Teflon parts over other methods? Unlock Precision & Complex Designs

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials