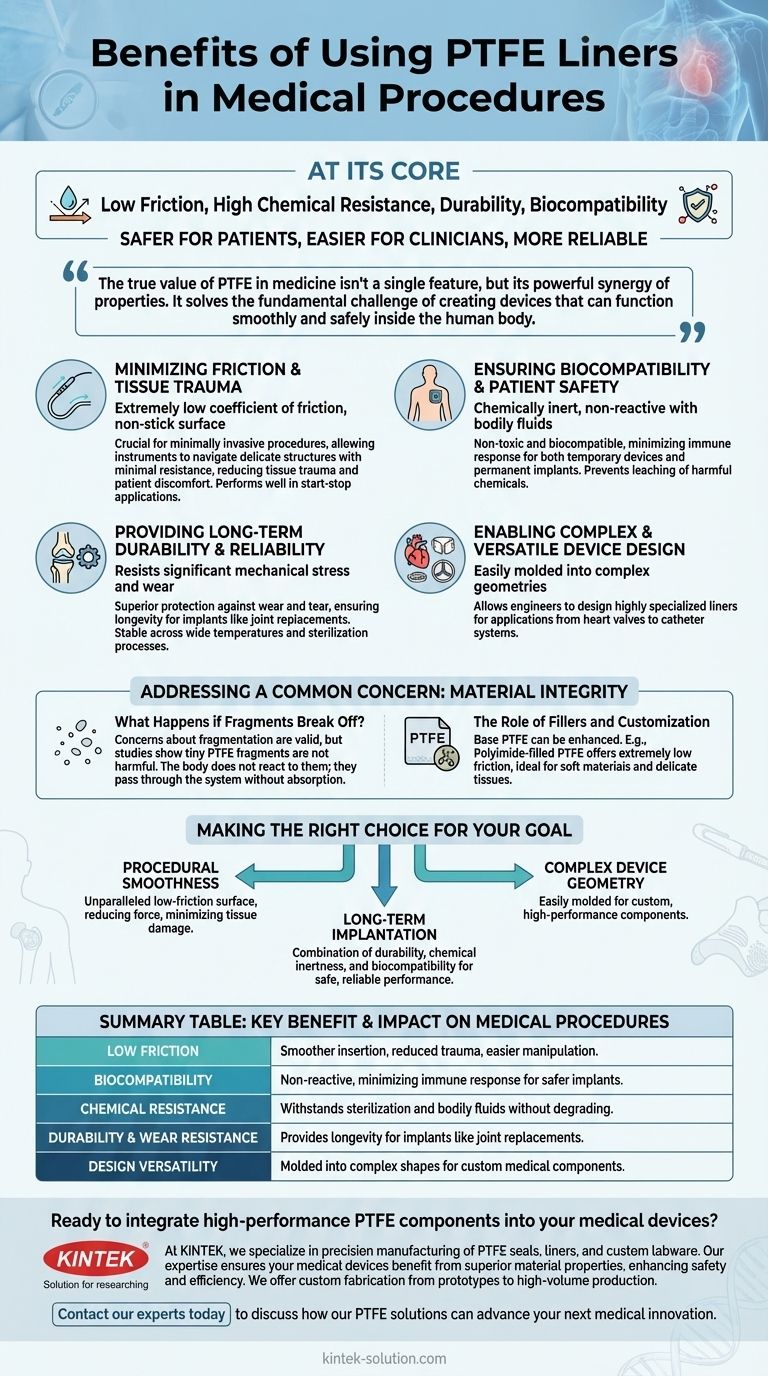

At its core, the primary benefits of using PTFE liners in medical procedures are their exceptionally low friction, high chemical resistance, durability, and biocompatibility. This unique combination of properties makes medical devices safer for the patient, easier for clinicians to use, and more reliable for long-term implantation in applications ranging from cardiovascular interventions to joint replacements.

The true value of PTFE in medicine isn't a single feature, but its powerful synergy of properties. It solves the fundamental challenge of creating devices that can function smoothly and safely inside the human body without causing harm or degrading over time.

The Core Advantages of PTFE in Medical Applications

Polytetrafluoroethylene (PTFE) is a cornerstone material in modern medical technology. Its molecular structure gives rise to several distinct advantages that directly improve procedural outcomes and patient safety.

Minimizing Friction and Tissue Trauma

The most celebrated property of PTFE is its extremely low coefficient of friction, resulting in a non-stick, slippery surface.

This is critical in minimally invasive procedures, as it allows catheters, guidewires, and other instruments to navigate delicate anatomical structures with minimal resistance. This reduces tissue trauma and patient discomfort.

This low-friction nature also performs exceptionally well in start-stop applications, which are common during surgical manipulations.

Ensuring Biocompatibility and Patient Safety

A material used inside the body must be non-reactive. PTFE is chemically inert, meaning it does not react with bodily fluids or tissues.

Because it is non-toxic and biocompatible, the body's immune system does not typically react to its presence, which is essential for both temporary devices and permanent implants.

This inertness also prevents the material from leaching harmful chemicals, ensuring patient safety over the long term.

Providing Long-Term Durability and Reliability

Medical implants, particularly in applications like joint replacements, must withstand significant mechanical stress and wear for years.

PTFE liners offer superior protection against wear and tear, ensuring the longevity and reliability of the device.

The material is also resistant to a wide range of temperatures, making it stable and dependable through sterilization processes and within the body's environment.

Enabling Complex and Versatile Device Design

Modern medical tools often require intricate and precise shapes to function correctly.

PTFE is valued for its ability to be easily molded into complex geometries. This allows engineers to design highly specialized liners for everything from heart valves to catheter systems.

Addressing a Common Concern: Material Integrity

While PTFE is highly durable, a natural question arises about the safety implications if the material were to degrade or shed particles over time.

What Happens if Fragments Break Off?

The concern over material fragmentation is valid for any implantable device.

Fortunately, studies show that should tiny fragments of PTFE come loose, they are not harmful. The body does not react to them, and they simply pass through the system without being absorbed.

The Role of Fillers and Customization

Base PTFE can be enhanced with fillers to optimize it for specific applications.

For example, polyimide-filled PTFE exhibits extremely low friction and is non-abrasive. This makes it ideal for use with very soft materials, such as plastics or certain biological tissues, ensuring smooth operation without damaging delicate adjacent surfaces.

Making the Right Choice for Your Goal

The decision to use PTFE is driven by the specific demands of the medical application.

- If your primary focus is procedural smoothness: PTFE's unparalleled low-friction surface is the key benefit, reducing force requirements and minimizing tissue damage during interventions.

- If your primary focus is long-term implantation: Its combination of durability, chemical inertness, and biocompatibility ensures the device will perform safely and reliably for years.

- If your primary focus is complex device geometry: The ease with which PTFE can be molded into intricate shapes makes it the ideal choice for custom, high-performance medical components.

Ultimately, PTFE's unique profile makes it an essential material for advancing the safety and effectiveness of modern medical procedures.

Summary Table:

| Key Benefit | Impact on Medical Procedures |

|---|---|

| Low Friction | Smoother device insertion, reduced tissue trauma, and easier surgical manipulation. |

| Biocompatibility | Non-reactive with bodily tissues, minimizing immune response for safer implants. |

| Chemical Resistance | Withstands sterilization and bodily fluids without degrading, ensuring long-term reliability. |

| Durability & Wear Resistance | Provides longevity for implants like joint replacements under mechanical stress. |

| Design Versatility | Can be molded into complex shapes for custom, high-performance medical components. |

Ready to integrate high-performance PTFE components into your medical devices?

At KINTEK, we specialize in the precision manufacturing of PTFE seals, liners, and custom labware. Our expertise ensures your medical devices for the semiconductor, medical, and laboratory industries benefit from superior material properties that enhance patient safety and procedural efficiency.

We offer custom fabrication from initial prototypes to high-volume production, guaranteeing components that meet your exact specifications for reliability and performance.

Contact our experts today to discuss how our PTFE solutions can advance your next medical innovation.

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Measuring Cylinders for Advanced Scientific and Industrial Applications

- PTFE Chemical Solvent Sampling Spoon

People Also Ask

- What finishing techniques are effective for machined Teflon parts? Achieve Functional Performance and Dimensional Stability

- What challenges arise when machining PTFE (Teflon)? Overcome Softness, Heat, and Instability

- What factors should be considered when choosing between Nylon and PTFE? Select the Right Material for Your Application

- What are the main applications of PTFE type Teflon? Unlock Its Versatility for Your Industry

- What are the unique properties of PTFE? The 3 Pillars Driving Demand for High-Performance Parts