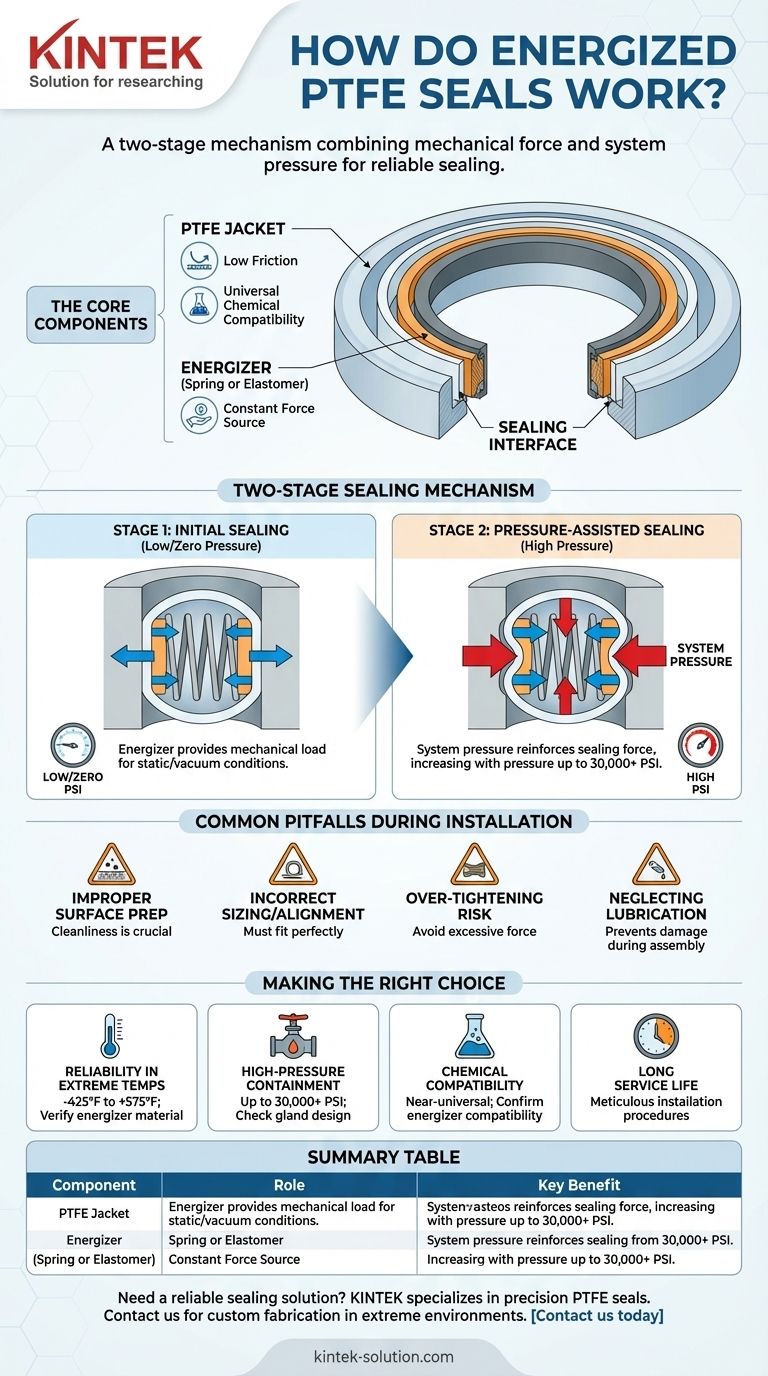

Energized PTFE seals work by using a two-stage mechanism that combines mechanical force with system pressure. A durable, corrosion-resistant energizer, typically a metal spring or an elastomer, provides an initial outward force on a precision-machined PTFE jacket. This initial force creates a reliable seal at low pressures, which is then powerfully reinforced by the system's own pressure to create an exceptionally tight barrier under demanding conditions.

The core principle is simple yet powerful: an internal energizer creates a constant, active sealing force, while the seal's design cleverly uses the system's own pressure to proportionally increase that force, ensuring a tight seal from zero to thousands of PSI.

The Core Components and Their Roles

To understand the seal's function, it's essential to look at its two primary components and the distinct job each one performs.

The PTFE Jacket: The Sealing Interface

The outer housing, or jacket, is machined from Polytetrafluoroethylene (PTFE). This material is chosen for its unique combination of properties.

Its extremely low coefficient of friction minimizes wear and allows for high-speed service, while its universal chemical compatibility makes it inert to nearly all industrial fluids and gases.

The Energizer: The Source of Constant Force

Inside the PTFE jacket sits the energizer. This component acts like a spring, providing the permanent elasticity that the more rigid PTFE material lacks.

When the seal is installed, the energizer is compressed. It constantly pushes the lips of the PTFE jacket outward against the sealing surfaces, ensuring a tight connection even when no system pressure is present.

The Two-Stage Sealing Mechanism Explained

The genius of this design lies in how it adapts to changing system pressure, ensuring reliable performance across a massive operating range.

Stage 1: Initial Sealing at Low and Zero Pressure

The energizer provides the initial mechanical load. This force is critical for creating a reliable seal in static, low-pressure, and vacuum conditions where there isn't enough system pressure to activate the seal on its own.

Stage 2: Pressure-Assisted Sealing

As system pressure increases, fluid enters the cavity of the seal. This pressure acts upon the inside surfaces of the PTFE jacket, adding to the outward force already being applied by the energizer.

This pressure-assist effect means the sealing force increases in direct proportion to the system pressure. The higher the pressure, the tighter the seal becomes, preventing leaks in high-pressure applications up to 30,000 PSI and beyond.

Common Pitfalls During Installation

While robust, the performance of an energized PTFE seal is highly dependent on correct installation. Failure to follow proper procedures can easily compromise the seal's integrity.

Improper Surface Preparation

Mating surfaces must be meticulously cleaned of all dirt, dust, and debris. Any contamination can create a leak path or damage the soft PTFE jacket during installation.

Incorrect Sizing or Alignment

Using a seal of the wrong size or failing to align it properly within the gland will cause uneven wear and inevitable leakage. The seal must sit perfectly between the mating parts with no gaps.

The Risk of Over-tightening

PTFE is a relatively soft material. Applying excessive force, especially by over-tightening fasteners, can deform or extrude the seal jacket. This permanently damages the seal and destroys its ability to function correctly.

Neglecting Lubrication

Lubricating the seal with a compatible fluid eases installation. This simple step prevents the seal from galling or tearing during assembly, which is a common cause of early-life failure.

Making the Right Choice for Your Goal

Understanding how these seals work allows you to apply them effectively to solve specific engineering challenges.

- If your primary focus is reliability in extreme temperatures: Verify the energizer material is rated for your specific cryogenic (-425°F) or high-heat (+575°F) environment, as this component is critical for maintaining force.

- If your primary focus is high-pressure containment: Ensure your gland design allows system pressure to properly actuate the seal and that all dimensions are machined to precise tolerances.

- If your primary focus is chemical compatibility: The PTFE jacket provides near-universal resistance, but always confirm the energizer material is also compatible with your media.

- If your primary focus is long service life: Prioritize meticulous installation procedures, especially surface cleanliness and using the correct torque, to prevent premature wear and damage.

By mastering its core principles of operation, you can leverage the full potential of this advanced sealing solution.

Summary Table:

| Component | Role | Key Benefit |

|---|---|---|

| PTFE Jacket | Sealing interface | Low friction, universal chemical compatibility |

| Energizer | Provides constant force | Maintains seal at low/zero pressure, adapts to system pressure |

| Two-Stage Mechanism | Combines energizer force and pressure-assist | Ensures reliability from vacuum to 30,000+ PSI |

Need a reliable sealing solution for demanding applications? KINTEK specializes in precision-manufactured PTFE seals, liners, and labware for semiconductor, medical, laboratory, and industrial sectors. Our custom fabrication services—from prototypes to high-volume orders—ensure optimal performance in extreme temperatures, high pressures, and corrosive environments. Contact us today to discuss your specific requirements and let our experts help you achieve leak-proof reliability!

Visual Guide

Related Products

- Custom PTFE Parts Manufacturer for Teflon Parts and PTFE Tweezers

- Custom PTFE Parts Manufacturer for Teflon Containers and Components

- Custom PTFE Sealing Tapes for Industrial and High Tech Applications

- Custom PTFE Sleeves and Hollow Rods for Advanced Applications

- Custom PTFE Bottles for Diverse Industrial Applications

People Also Ask

- What are the future considerations for machining Teflon? Mastering Material Challenges with Smart Tech

- What are the key considerations when machining Teflon? Master Precision Machining for Soft Polymers

- What are the key advantages of PTFE? Unmatched Performance for Extreme Environments

- How does PTFE contribute to low friction and wear resistance? Achieve Superior Performance with Advanced Materials

- What tips can improve Teflon machining results? Master Sharp Tools, Heat Control, and Rigid Support